Your workers are leaving. Theirs are lining up. The difference between 38% turnover and under 1% isn’t money—it’s a $5,000 decision you haven’t made yet

EXECUTIVE SUMMARY: The average dairy loses 38% of its workers every year—and at $15,000 a head, that’s $100,000+ walking out your driveway. Money that never produces a single pound of milk. Sandy Larson was trapped in the same cycle until she made a decision most owners won’t: she became a landlord. Her Wisconsin operation went from 7% turnover to under 1%. Now there’s a waiting list to work there. Cornell research confirms it—structured onboarding alone cuts turnover nearly in half. The fix isn’t higher wages. It’s treating labor like the capital investment it actually is. Here’s the math, the proof, and the playbook.

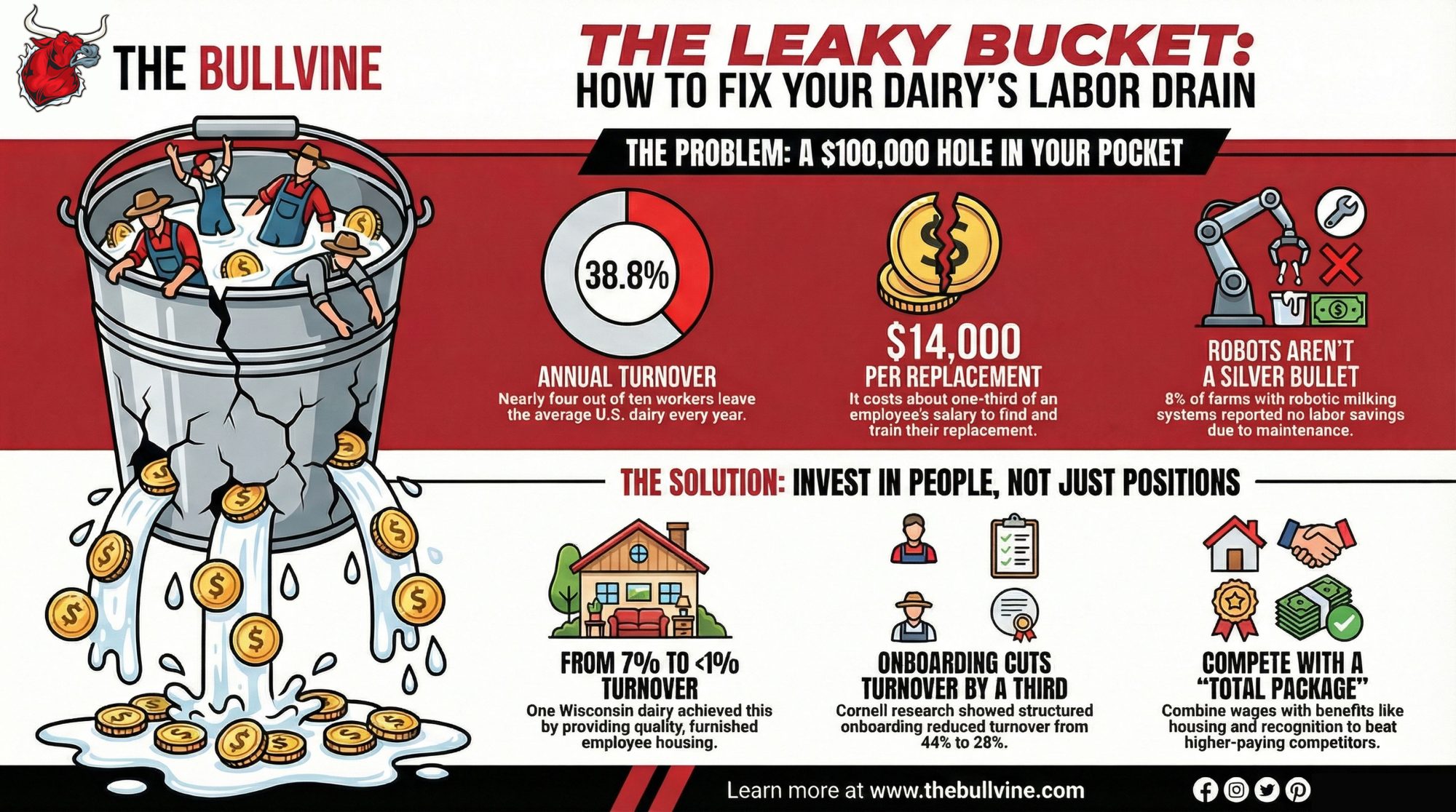

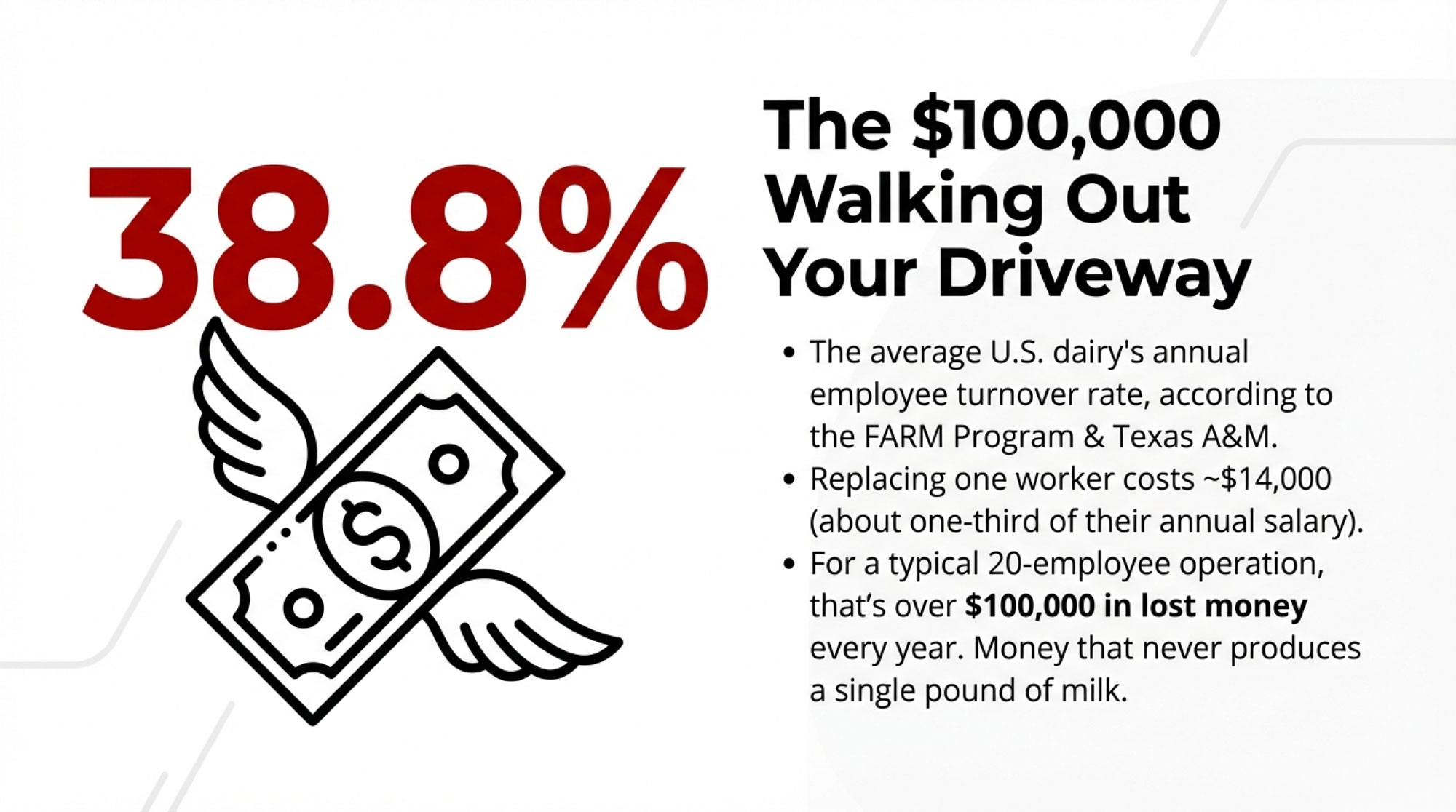

Let’s be blunt: The average U.S. dairy loses nearly four out of ten workers every single year. According to the FARM Program and Texas A&M, that 38.8% turnover rate isn’t just a “headache”—it’s a financial hemorrhage.

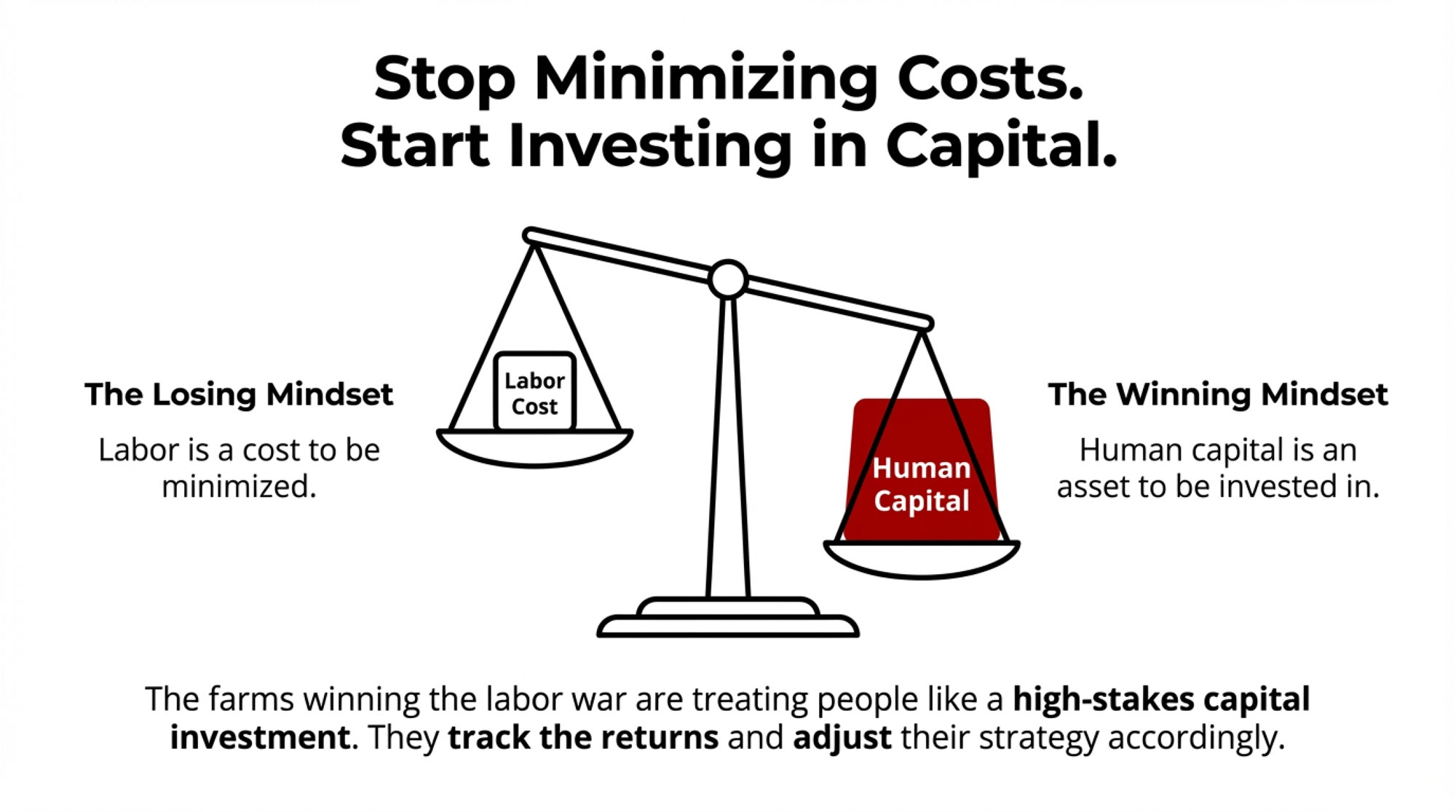

If you’re running a 20-employee operation, you aren’t just losing people; you’re watching $100,000 walk out the driveway annually in replacement costs. That’s money that doesn’t produce a single pound of milk. With Class III milk hovering in the high teens and component premiums tightening margins across most regions, every operational efficiency matters more than it did five years ago. It’s time we stop treating labor as a “cost to be minimized” and start treating it like the high-stakes capital investment it actually is.

| Operation Size | Average Turnover Rate | Workers Lost Annually | Annual Turnover Cost |

| Small (10 employees) | 38% | 3.8 workers | $52,000 |

| Medium (20 employees) | 38% | 7.6 workers | $104,000 |

| Large (50 employees) | 38% | 19 workers | $260,000 |

| Experienced Worker Loss | 38% | Per worker | $20,000+ |

| Industry Best (Larson Acres) | <1% | 0.5 workers (50 employees) | $7,000 |

The FARM Program’s nationwide survey—conducted by Texas A&M’s Center for North American Studies with over 630 dairy farms participating—found that replacing a worker typically costs about one-third of their annual salary. With average dairy compensation running around $42,000, you’re looking at $13,000 to $14,000 per departure. For experienced hands who know your herd, your protocols, your fresh cow management inside and out? That number climbs past $20,000.

So what separates the farms drowning in turnover from the ones that have essentially solved it? It’s not geography. It’s not wage rates. It’s not luck. It’s how they think about their people.

How Employee Housing Transformed One Wisconsin Dairy

When Sandy Larson, general manager at Larson Acres near Evansville, Wisconsin, started hearing employees mention housing as a reason for choosing other employers back in 2019, she made a decision that seemed counterintuitive at the time: she’d take on the responsibility of becoming a landlord.

“That was the one thing that I thought I could change that would help the culture and keep our employees wanting to be at Larson Acres every day,” Larson shared on the Uplevel Dairy Podcast a few years back.

You know how it goes—you identify a problem, and you find a way to address it. Today, nearly half of her 75 employees live in housing provided by the farm. Some of it’s farm-owned, some are rentals where Larson Acres holds the leases. Either way, the results speak for themselves.

“Our turnover rate has dropped from 7% to under 1%,” Larson says. “We have a waiting list of people that want to work here because we’re taking care of the employees.”

What she’s discovered is that housing isn’t just a benefit—it creates a genuine competitive advantage. And the practical details matter here. Furnishing units completely so workers can walk into a home that’s ready to be lived in. Handling seasonal needs like A/C units come summer and salt and shovels before winter hits. Covering wireless internet as part of the rent. Grouping employees by shift compatibility to avoid disrupting each other’s sleep schedules.

It’s work—Larson visits homes monthly and manages relationships with multiple landlords. But the return on that effort shows up across the operation.

“The culture at the farm, the cow care, the somatic cell count, the milk production… it’s all clicking,” she explains. “And it’s all tied in together with a good working environment and a good home.”

The True Cost of Dairy Employee Turnover

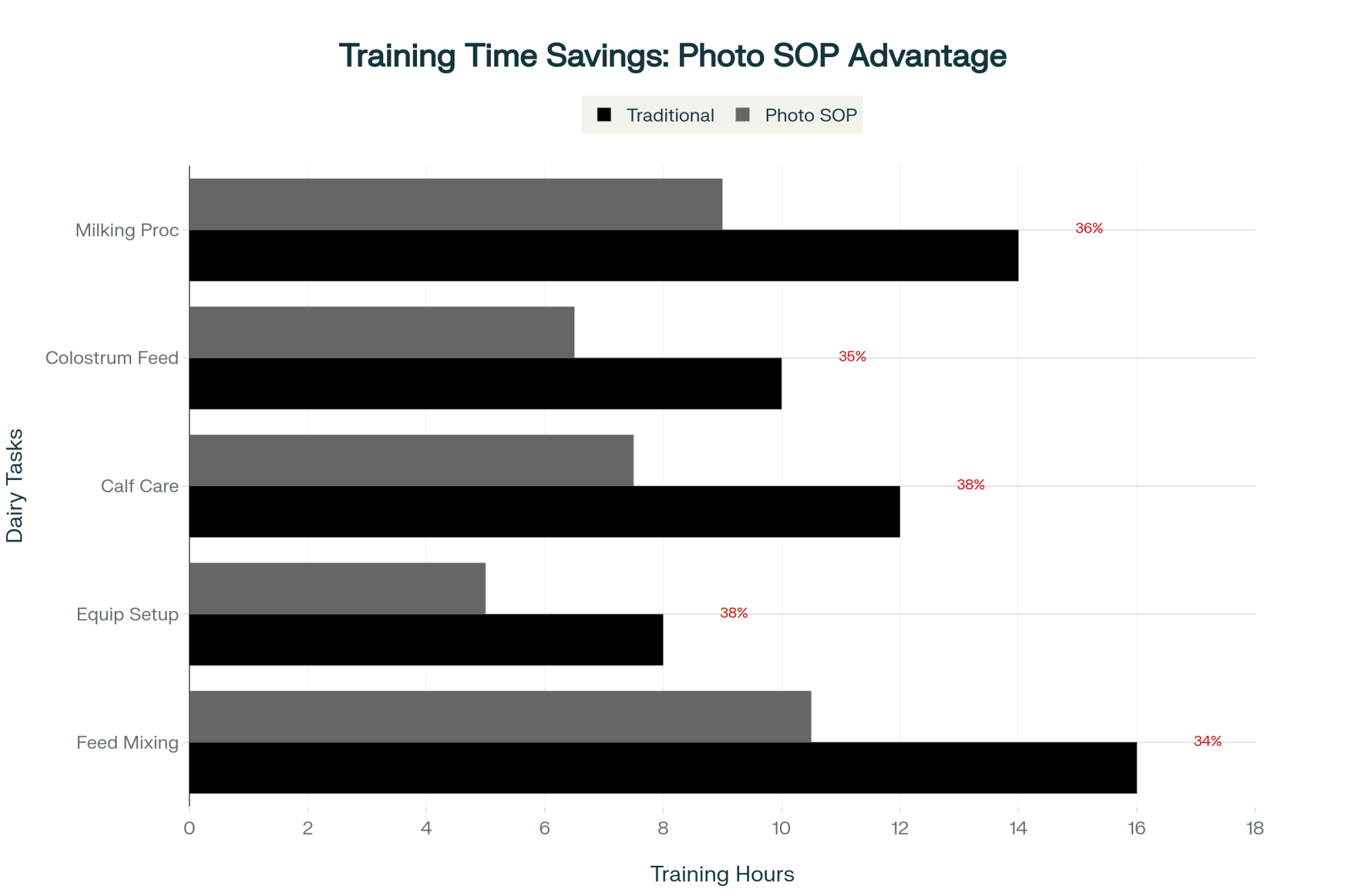

What makes turnover expensive isn’t just the obvious stuff—posting job ads, interviewing candidates, sorting paperwork. It’s everything that happens after someone new walks through the door. As many of us have seen, the new hire spends their first few weeks learning the ropes, while your experienced people spend their time teaching rather than doing their actual jobs.

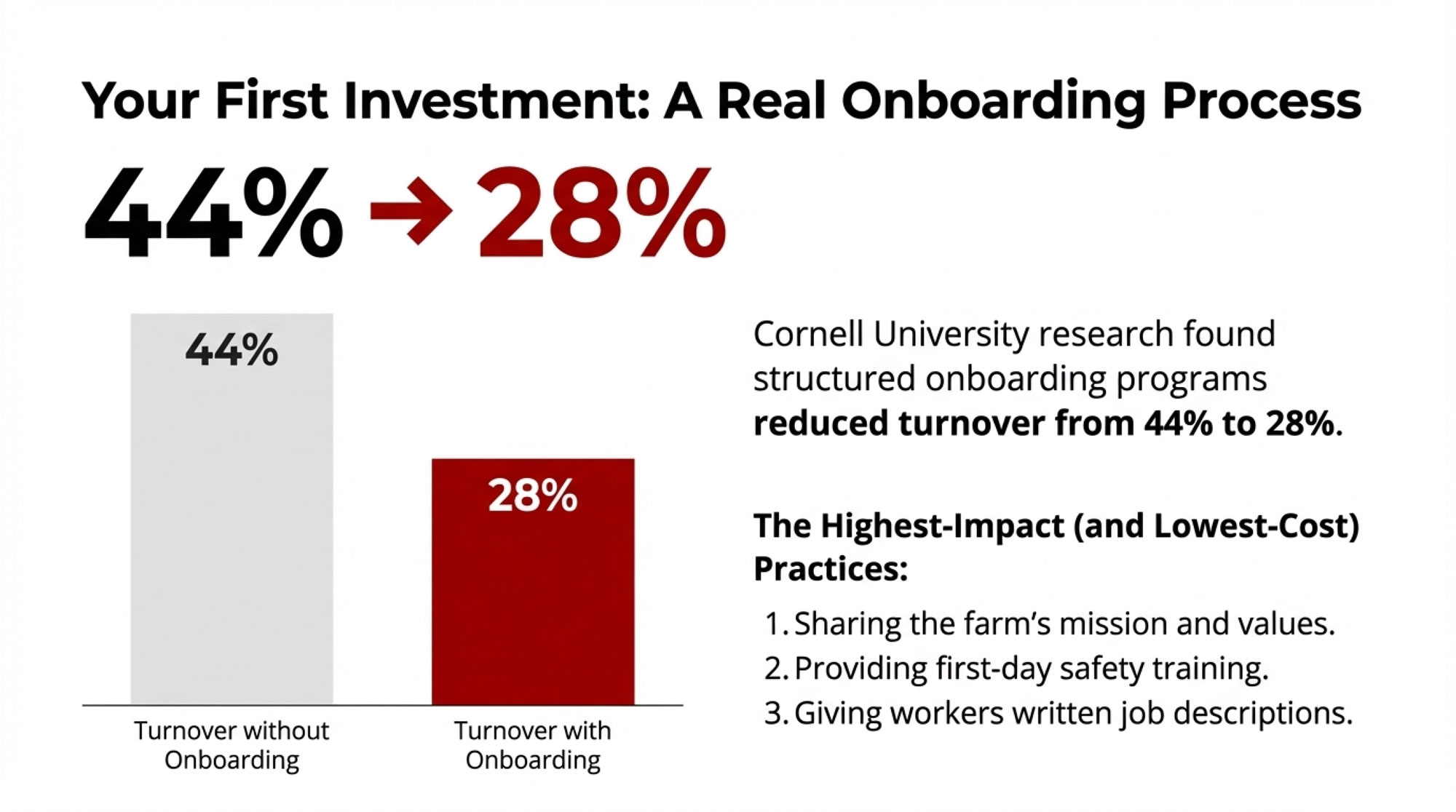

Richard Stup, who leads the Agricultural Workforce Development program at Cornell, has spent years studying what actually happens when farms bring on new people. His team’s research, published in the Journal of Dairy Science earlier this year, found that structured onboarding programs reduced turnover from 44% to 28% among participating farms. Now, the sample size meant this wasn’t statistically significant, but the direction is encouraging—and worth watching as more data comes in.

More importantly, farms that implemented formal onboarding saw real improvements in how they do things day to day. Of 23 recommended onboarding practices, participating farms tripled their adoption of mission statements, first-day safety training, and written job descriptions. Five other practices more than doubled.

What that tells us is pretty straightforward: most farms aren’t doing the basics yet. And when you’re not doing the basics, you’re essentially running a perpetual training operation.

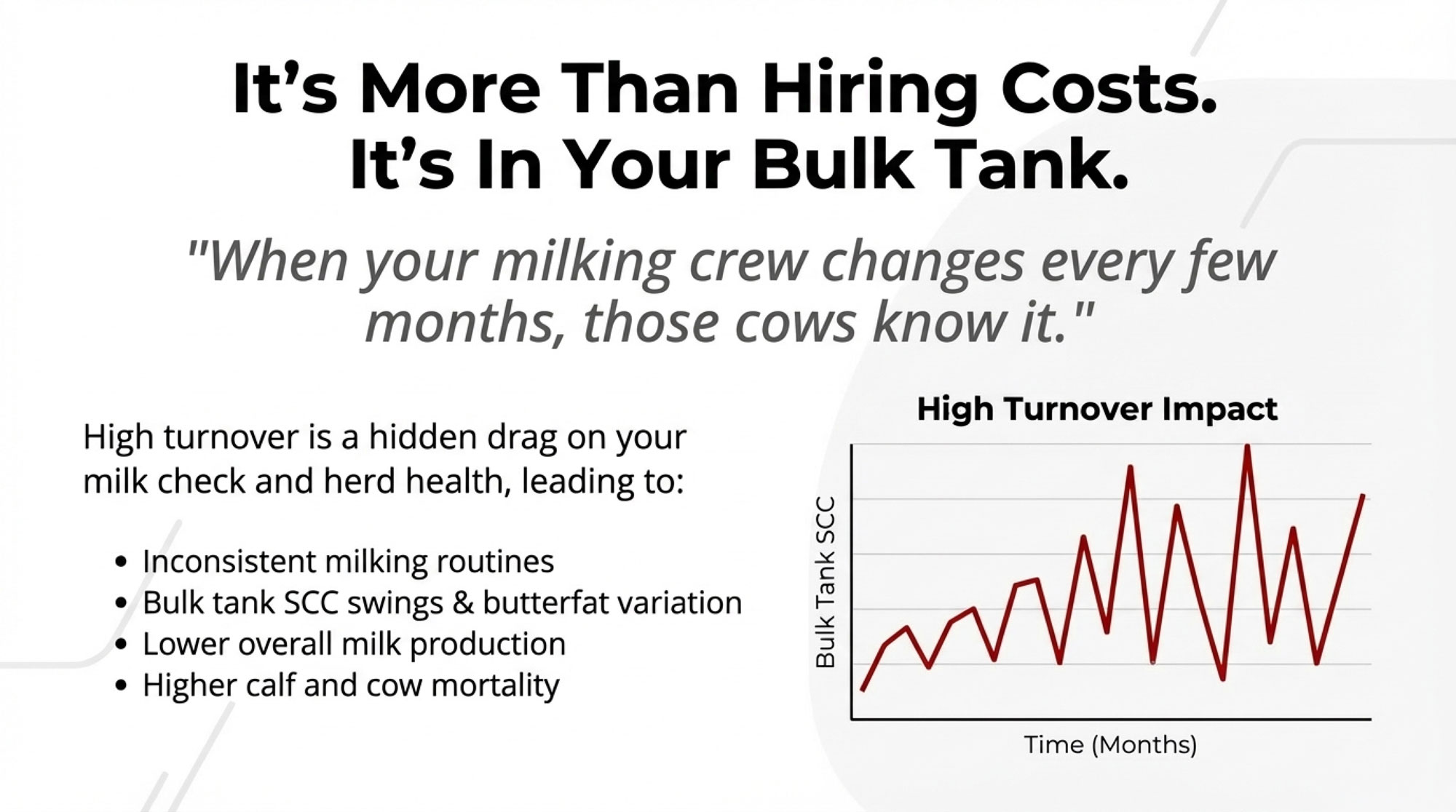

Beyond those direct replacement costs, the connection between workforce stability and production outcomes is consistently evident across industry research. While specific figures vary depending on how you measure things, the pattern is clear: operations with high turnover generally see lower milk production, higher calf mortality, and higher cow mortality than operations that keep their people around.

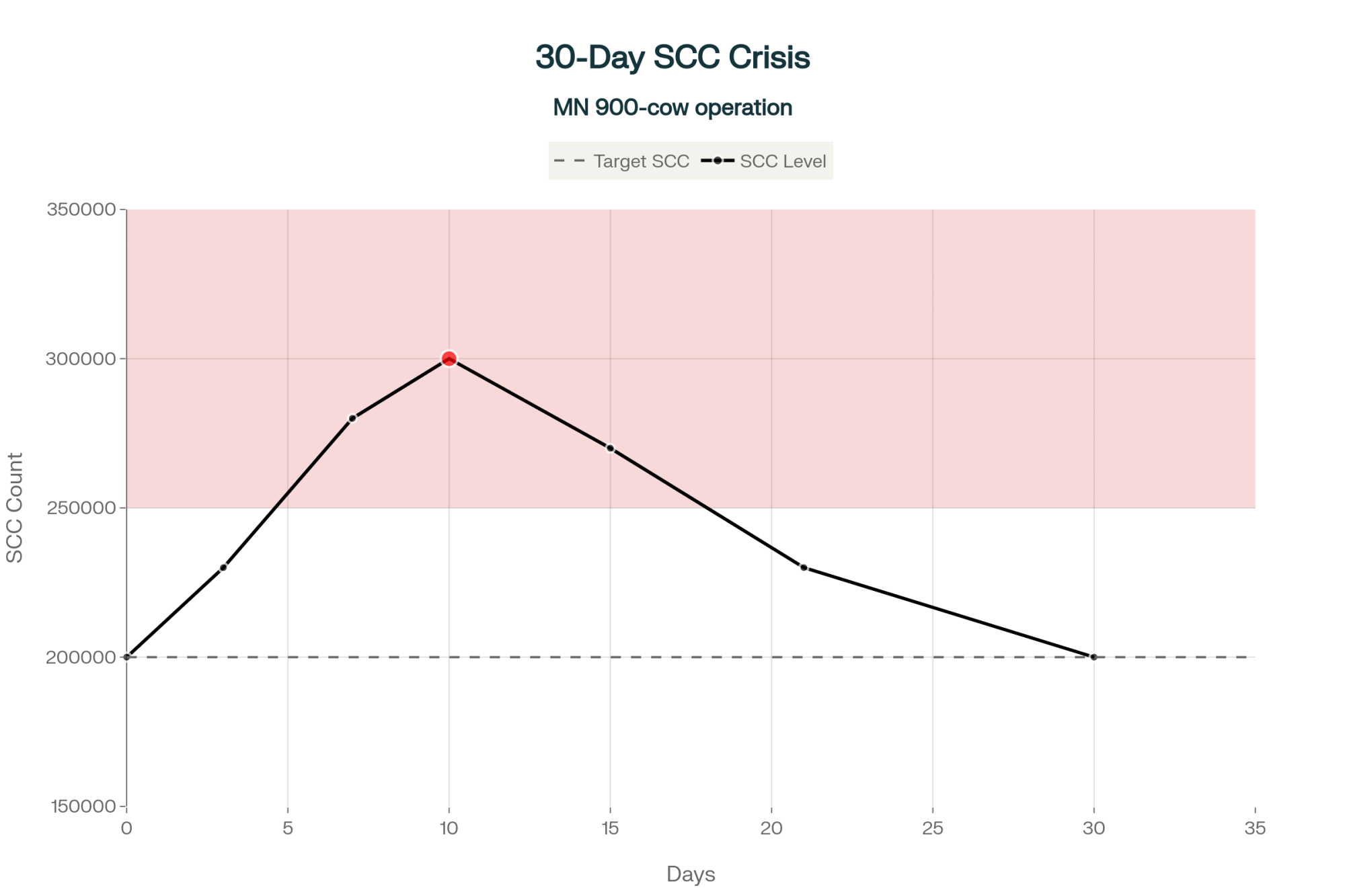

And here’s something that doesn’t always make it into the turnover conversation: inconsistent milking routines from constant staff changes can show up in bulk tank SCC swings and butterfat variation—subtle hits to your milk check that don’t always get traced back to staffing issues. When your milking crew changes every few months, those cows know it. Consistency in stockmanship, feeding protocols, and fresh-cow management. New people, no matter how capable, need time to develop those instincts.

Understanding Today’s Dairy Workforce

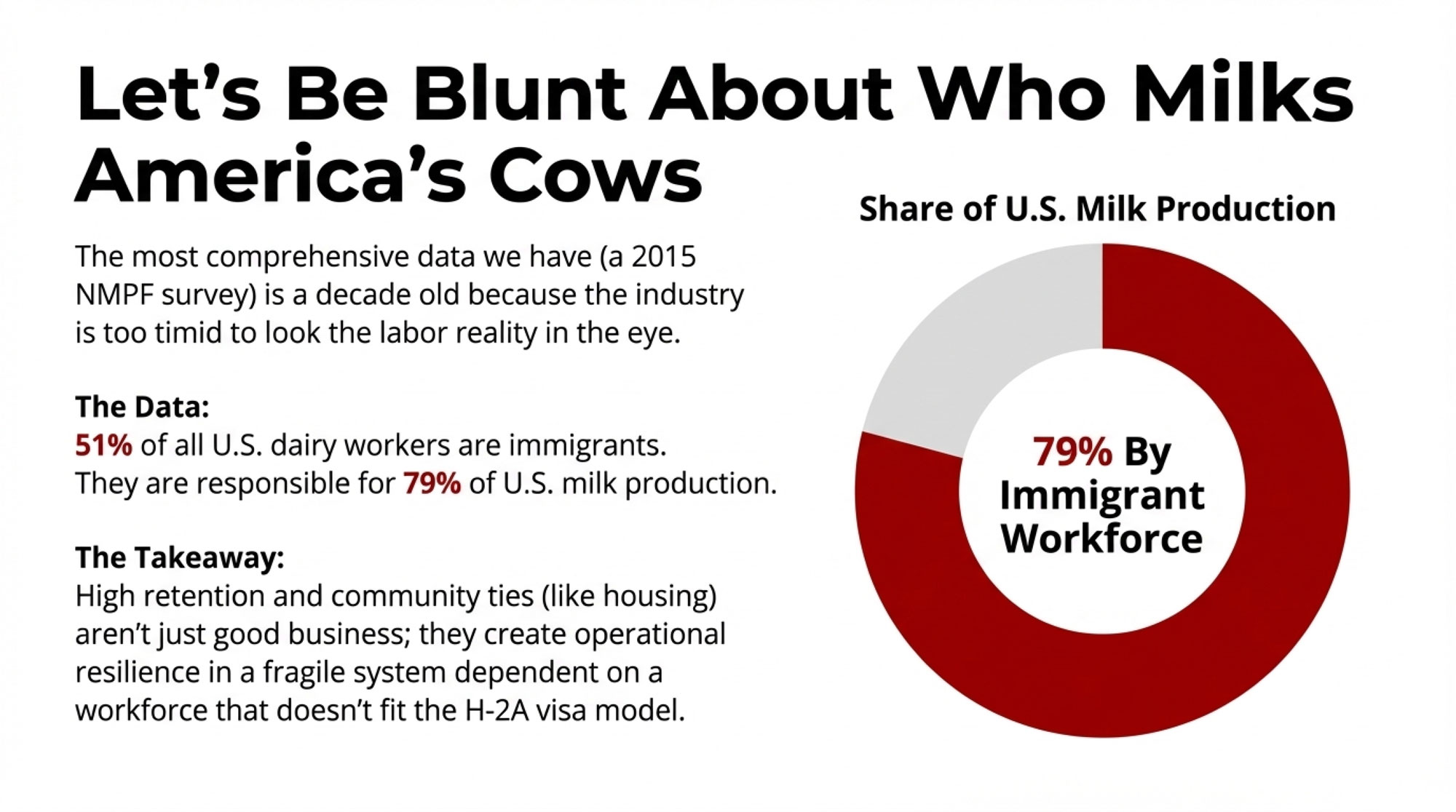

Any honest conversation about dairy labor has to acknowledge who’s actually doing this work. The most comprehensive assessment we have comes from a 2015 National Milk Producers Federation survey, which found that 51% of dairy workers are immigrants. According to that same research, those workers are responsible for 79% of U.S. milk production.

Now, I want to be straight with you—that data is a decade old. Comprehensive updated surveys simply haven’t been conducted, which is a gap in our understanding that deserves attention. That said, most industry observers suggest immigrant workforce percentages have remained stable or increased slightly since then.

Let’s stop pretending we don’t know who is milking the cows. The data is a decade old because the industry is too timid to look the labor reality in the eye. Whether it’s 2015 or 2026, the immigrant workforce is the backbone of the American bulk tank.

Jaime Castaneda, who serves as executive vice president for policy and strategy at NMPF, spoke earlier this year about the industry’s ongoing efforts to improve access to the H-2A visa program. The challenge, as he explained it, is that the year-round nature of dairy work doesn’t fit a visa system designed for seasonal agriculture.

“We have written to the Department of Labor a number of different times and actually even pointed to the fact that the sheep herding industry has access to H-2A, and it’s a very similar industry to dairy,” Castaneda noted.

This creates real operational vulnerability for farms across the country. What I’ve noticed is that farms with the strongest retention practices tend to have somewhat more resilience here. Workers who’ve been somewhere for years, who have housing, whose kids attend local schools—they’re more embedded in the community. Operations with high turnover and no housing or community ties face a very different situation.

Why Robotic Milking Systems Aren’t the Complete Labor Solution

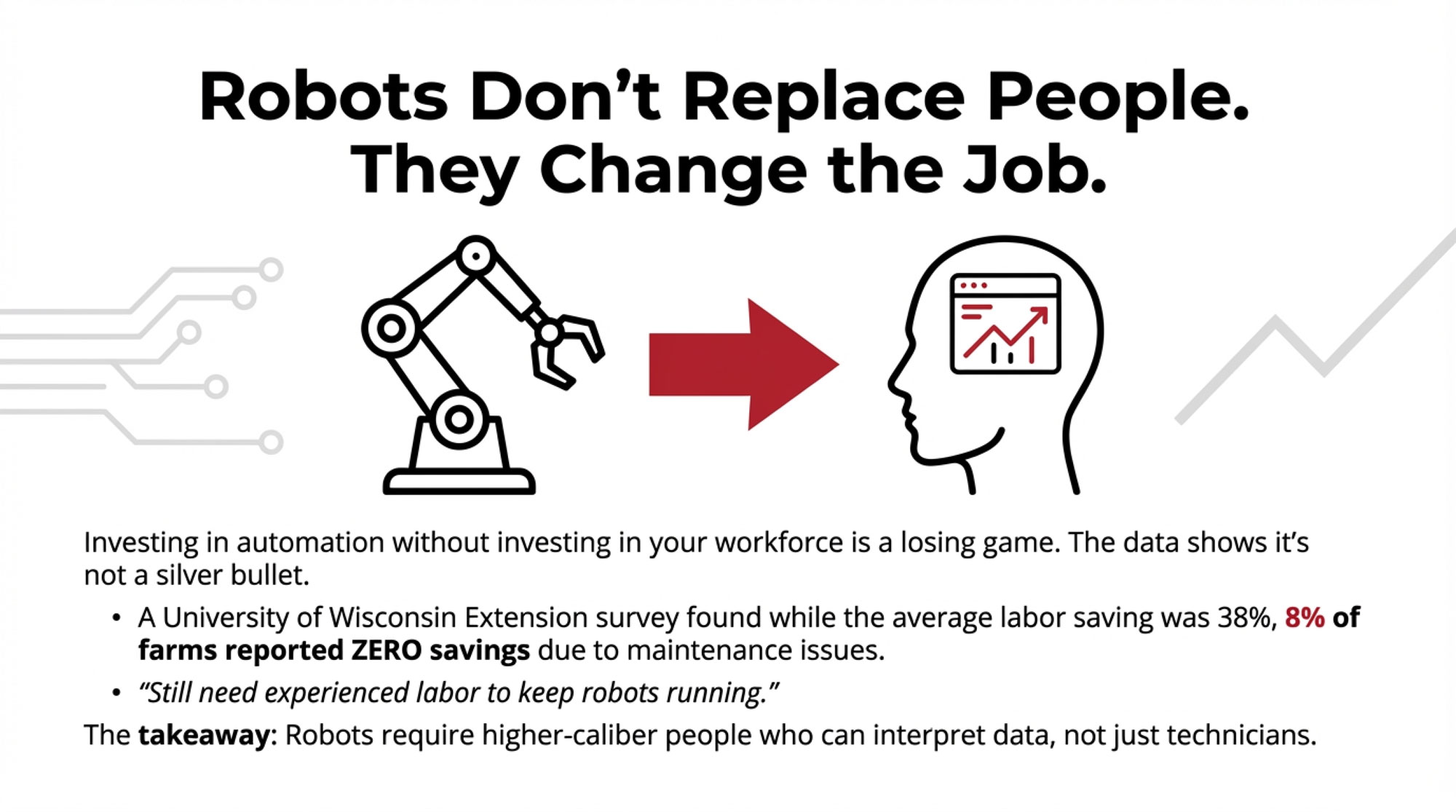

I’ve watched many farms invest in robotic milking systems, expecting significant reductions in labor costs. And look, automation absolutely has its place. But the reality has been more nuanced than the sales presentations often suggest.

Research from the University of Wisconsin Extension tells an interesting story. They surveyed 50 dairy producers who’d adopted automated milking systems, and while the average labor-saving was about 38% per cow, there was enormous variation in outcomes. At the lower end, 8% of respondents reported no labor savings at all, citing maintenance and repair issues as their primary concern.

| Retention Strategy | Implementation Cost | Turnover Reduction | Payback Period | Example |

| Structured Onboarding | $5,000-8,000 | 16 points (44%→28%) | <1 year | Cornell study |

| Employee Housing (Owned) | $75K-150K/unit | 6+ points (7%→1%) | 2-3 years | Larson Acres |

| Housing (Rental Subsidy) | $500-800/mo/worker | 4-6 points | 1-2 years | Regional |

| Recognition Programs | $2K-3K/year | 2-4 points | Immediate | Vir-Clar Farms |

| Transportation Support | $3K-5K/year | 1-3 points | <1 year | Vir-Clar Farms |

| Referral Bonuses | $500-1K/hire | 1-2 points | Immediate | Vir-Clar Farms |

| Do Nothing (Baseline) | $0 | 0 points (38.8% avg) | N/A | Industry avg |

One producer comment from that survey captured it well: “Anyone considering robotics should understand that there is still plenty of daily work involved in milking, robots just give you more flexibility with your time.”

Another was more direct: “Still need experienced labor to keep robots running.”

Dr. Trevor DeVries, who holds the Canada Research Chair in Dairy Cattle Behaviour and Welfare at the University of Guelph, has extensively researched robotic milking systems. His work highlights an important point: the technology doesn’t eliminate the need for skilled workers—it transforms the skills needed.

“Automated milking systems allow dairy cows to choose when and how often they want to be milked, which may increase production and help reduce stress,” DeVries has explained. “These systems also record data that farmers can use to improve management efficiency.”

That data management piece deserves attention. Robots generate substantial information about individual cow behavior, milk production, and health indicators. Getting value from that data requires people who can interpret it and act accordingly—a different skill set than conventional milking and often a higher-paid one.

The farms succeeding with automation tend to be those that invested in workforce development alongside technology investment. Technology and human capital work together, not as substitutes.

Low-Cost Retention Strategies That Deliver Results

But technology investments aside, some operations are finding retention success through approaches that cost almost nothing in capital—just consistent attention and follow-through.

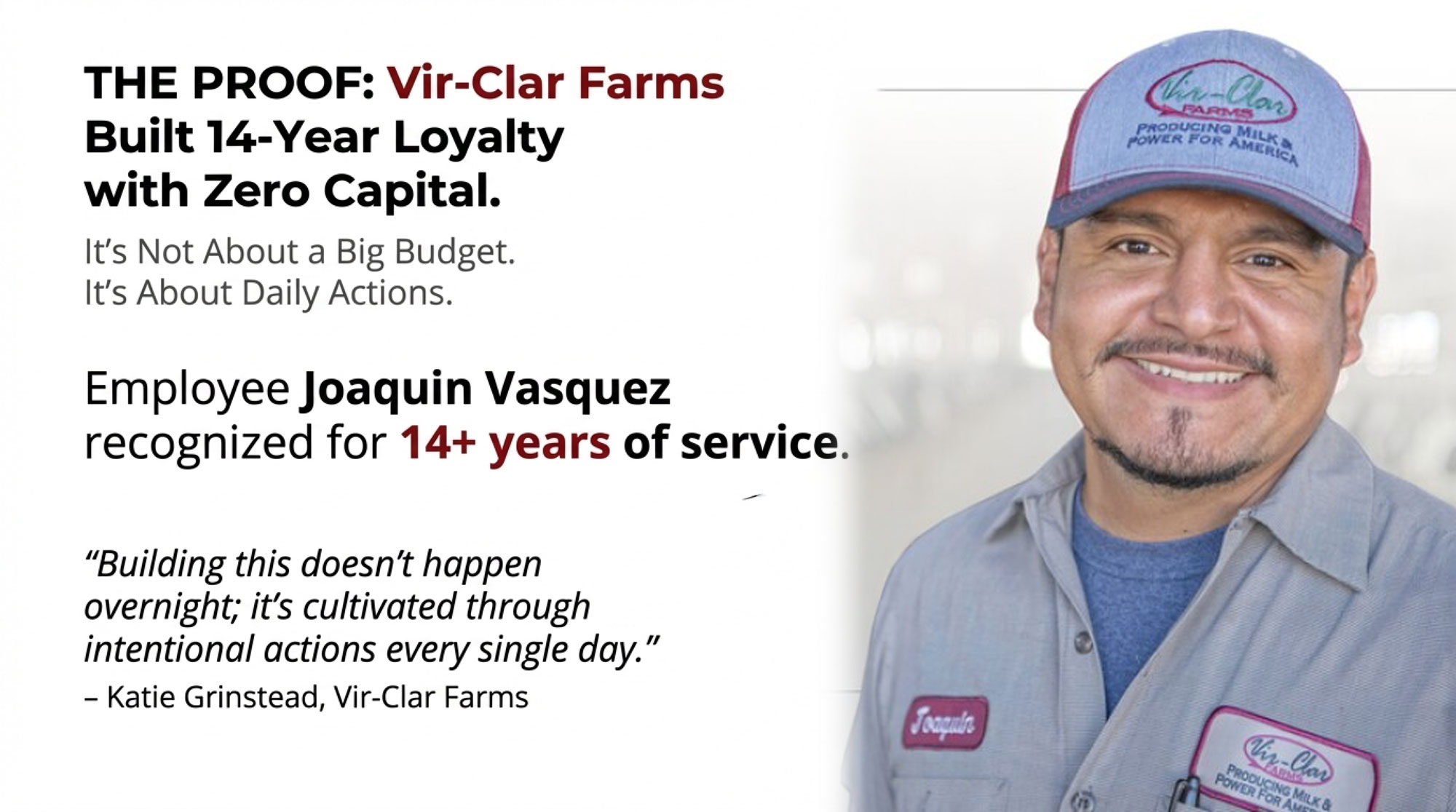

Katie Grinstead, who owns Vir-Clar Farms in Fond du Lac, Wisconsin, has built loyalty through a combination of smaller but steady practices. She’s talked about how tracking vacation accrual has become a useful proxy for workforce stability at her operation—employees have to put a year in before they earn vacation hours, and watching how many people hit that milestone tells you something about how you’re doing.

Her employee Joaquin Vasquez, who’s been with the farm for more than 14 years, received recognition from Farm Journal’s Milk Business program in 2024. That kind of tenure doesn’t happen by accident—it’s built through deliberate effort.

What Vir-Clar does includes a ride-share program for employees without transportation (something Grinstead started after seeing another farmer do it successfully), birthday celebrations for all team members, holiday gatherings with bonuses, summer picnics, referral bonuses that recognize both the referrer and newcomer if they stay past 30 days, and internal promotion priority before outside hiring.

“If you can get employees to stay, they get to see all of the benefits we offer,” Grinstead explains. “We couldn’t do what we do every day without our team. To be successful, we need a group of people committed to our vision. Building this doesn’t happen overnight; it’s cultivated through intentional actions every single day.”

That phrase—intentional actions every single day—is worth sitting with. It’s not a program you implement once and move on from. It’s a way of operating.

And it’s not just a Midwest phenomenon. I’ve seen similar commitment paying off on operations from California’s Central Valley to Arizona’s dry lot dairies to smaller family operations in Vermont and upstate New York—the specific tactics vary based on regional labor markets and housing costs, but the underlying commitment to treating workers as long-term investments rather than interchangeable costs shows up wherever retention is working.

What Dairy Workers Actually Want

Here’s something that might shift how you think about this: industry surveys increasingly show that employee retention has become a top human resource concern for agriculture and food employers, in many cases, overtaking talent acquisition as the primary focus. That’s a meaningful shift from where things stood just a few years ago.

It makes sense when you consider what we’re learning about worker preferences. Multiple surveys have found that benefits often matter more than wage increases alone—which helps explain why some lower-paying operations retain workers while competitors paying more can’t seem to keep anyone. It’s a counterintuitive finding, but one worth considering.

For dairy specifically, the Canadian Agricultural Human Resource Council’s research indicates that dairy operations experience lower voluntary turnover than the broader agriculture sector. That relative stability suggests our industry has some structural advantages—year-round employment, potential for skill development, and often closer relationships between employers and employees on smaller operations.

The question is whether individual farms can capitalize on those structural advantages through deliberate retention practices, or whether we’ll lose that potential through inattention.

Competing With Processing Plants for Workers

There’s another dimension to this challenge that’s easy to overlook: you’re not just competing with other farms for workers—you’re competing with processing plants, manufacturing, construction, and retail.

Processing facilities often offer entry-level wages of $22-23/hour with full benefits and climate-controlled work environments. For workers comparing that to farm positions with irregular hours, weather exposure, and physical animal handling requirements… well, the calculation isn’t always in our favor.

| Compensation Component | Processing Plant | Farm (No Housing) | Farm (With Housing) | Competitive Gap |

| Base Hourly Wage | $22.50 | $18.00 | $18.00 | -$4.50/hr |

| Annual Base (2,080 hrs) | $46,800 | $37,440 | $37,440 | -$9,360 |

| Housing Value | $0 | $0 | $12,000 | +$12,000 |

| Work Environment | Climate-controlled | Weather-exposed | Weather-exposed | Variable |

| Shift Flexibility | Fixed schedule | Some flexibility | Some flexibility | Moderate + |

| Skill Development | Repetitive tasks | Livestock mgmt | Livestock mgmt | High + |

| Community/Culture | Industrial | Relationship-based | Relationship-based | High + |

| Total Annual Value | $46,800 | $37,440 | $49,440 | +$2,640 |

This creates a frustrating dynamic. You invest in developing workers, building dairy knowledge over months or years, then watch those trained employees get recruited by processors offering better compensation—without having invested in that development themselves.

The farms that successfully retain workers despite this competition typically offer something processors can’t easily match: total employment value that includes housing, advancement opportunities, work variety, and a relationship-based culture. When you factor in housing worth $10,000-15,000 annually, an $18/hour farm position starts looking genuinely competitive with a $23/hour processing job. It’s about the complete package.

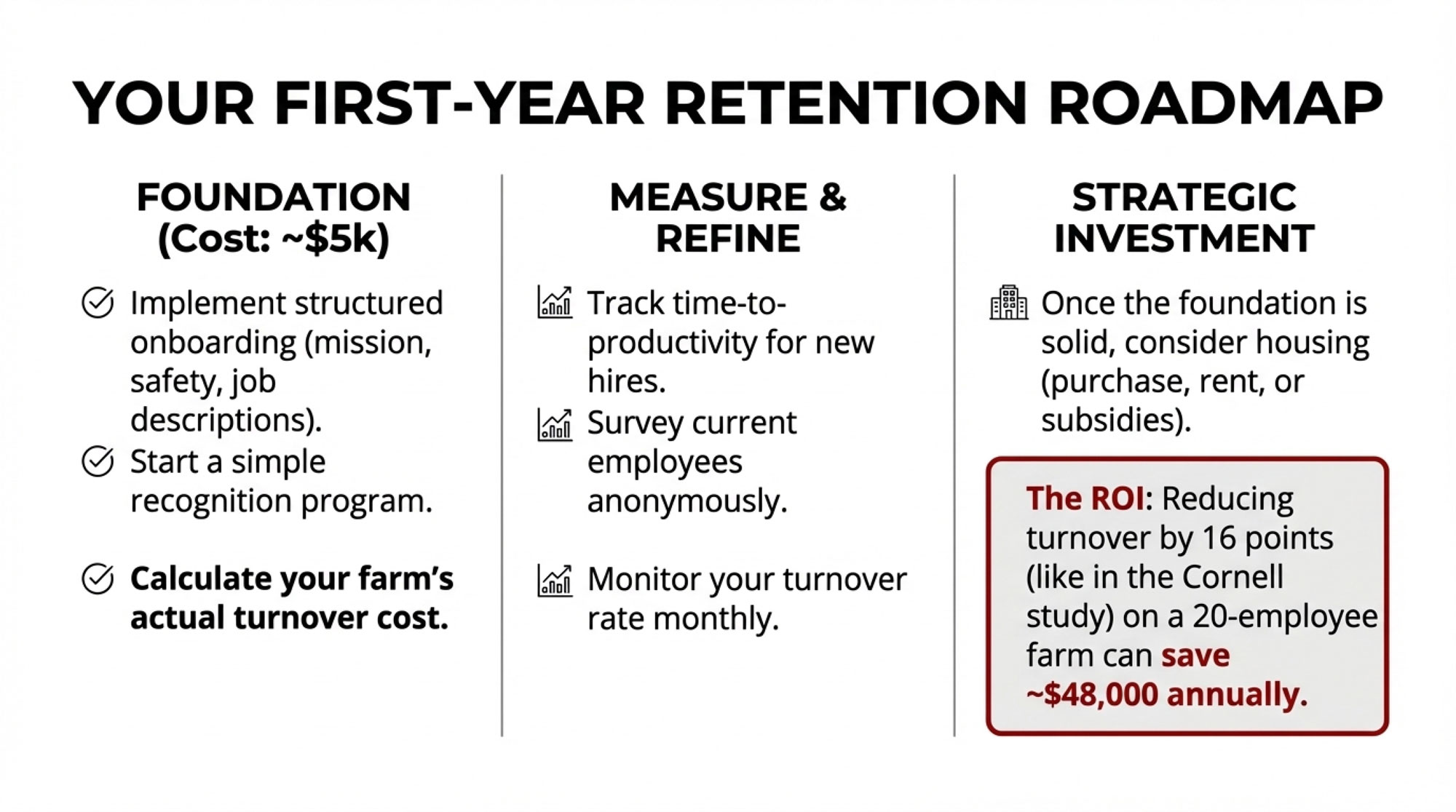

Building Your Retention Program: A First-Year Roadmap

For operations ready to improve workforce outcomes, the research and case studies suggest a phased approach works better than trying to change everything at once.

Start with the fundamentals. The Cornell research found that farms implementing structured onboarding saw the biggest gains in practices that cost almost nothing: sharing your mission and values with new hires, providing first-day safety training, and giving workers written job descriptions. These are standard practices in most industries that agriculture has largely overlooked.

You’re probably looking at $5,000-8,000 for template development and mentor training—real money, but not prohibitive.

Recognition programs similarly require minimal cash—maybe $2,000-3,000 annually for birthday acknowledgments, referral bonuses, team meals—but they signal to workers that they’re valued as individuals rather than interchangeable positions.

Then measure what’s happening. Track time-to-productivity for new hires. Survey existing employees anonymously about their satisfaction and opportunities for improvement. Calculate your actual turnover costs so you know whether your interventions are working.

The Stup research is instructive here: farms that implemented structured practices saw turnover drop from 44% to 28%. That 16-percentage-point improvement, on a 20-employee operation at $15,000 per departure, represents roughly $48,000 in annual savings. That’s meaningful money.

If early changes show improvement, consider strategic investment. Housing investment will compound those gains if you’ve got the cultural foundation in place. The math varies by region and approach—purchased mobile homes, new construction, and rental partnerships all have different cost structures. What works in rural Wisconsin at $75,000 per unit might cost $150,000 or more in California dairy regions, so local housing markets matter when you’re penciling out the numbers.

Larson’s experience suggests payback periods of 2-3 years are achievable in many situations. For operations that can’t access capital for housing, rental subsidies offer a middle path—guarantee leases, subsidize rent, and provide the stability benefits without full ownership.

Tailoring Your Approach by Operation Size

What works for a 75-employee dairy in Wisconsin isn’t necessarily appropriate for a 200-cow family operation in Vermont or a 5,000-head facility in Idaho. Similar retention approaches have shown results across operations from the Pacific Northwest to the Northeast, though specific implementations vary by regional labor markets and operational context.

Smaller operations—say, under 50 cows with primarily family labor—often face challenges in transition planning and family dynamics rather than employee retention. But even operations with minimal hired labor benefit from documenting protocols and creating clear expectations. If nothing else, it makes eventual expansion or transition more manageable.

Mid-size operations—somewhere in the 100-500 cow range with mixed family and hired labor—this is where retention investments often deliver the strongest return. You’re large enough that turnover costs really add up, but small enough that culture changes can happen relatively quickly. Housing investment becomes feasible, structured onboarding makes sense, and career pathways can be meaningful even with a modest organizational structure.

Large operations—500-plus cows with primarily hired labor—scale creates both opportunities and challenges. You can potentially offer better benefits packages and more formal advancement structures. But you’re also competing more directly with processors and other large employers, making it harder to maintain culture across shifts and locations.

The Bottom Line

The dairy operations figuring out workforce stability aren’t doing anything magical. They’re treating human capital as actual capital—investing in it strategically, tracking returns on that investment, and adjusting based on results.

Sandy Larson didn’t have special advantages when she started managing housing. She had a hypothesis that taking care of employees would pay returns, a willingness to test it, and the discipline to execute consistently. Three years later, she has a waiting list of applicants while competitors struggle to staff basic positions.

Katie Grinstead at Vir-Clar doesn’t have a massive budget for employee programs. She has a commitment to “intentional actions every single day”—small practices that add up over time into a culture where someone stays for 14 years and earns recognition for it.

Research from Cornell, Wisconsin Extension, the University of Guelph, and others isn’t prescriptive about exactly what every farm should do. It’s descriptive about what tends to work and what doesn’t. The common thread: operations that invest deliberately in their people—through housing, training, recognition, advancement opportunity, or some combination—generally outperform those that treat labor primarily as a cost to minimize.

That’s not a revelation. It’s a reminder that what’s obvious in principle requires actual execution in practice. The farms winning the labor war aren’t smarter than everyone else. They’re just more consistent about doing what they know works.

The question isn’t whether you can afford to invest in your workforce. It’s whether you can afford not to.

Key Takeaways

What the research tells us:

- Average dairy turnover runs 38.8% annually, according to the FARM Program nationwide survey

- Replacement costs typically run about one-third of annual salary—roughly $13,000-$14,000 for most positions, higher for experienced workers

- Workforce instability correlates with production challenges, increased mortality, and subtle milk quality issues like SCC swings and component variation

What’s working:

- Housing investment at Larson Acres dropped turnover from 7% to under 1%

- Structured onboarding in the Cornell study reduced turnover from 44% to 28%

- Recognition programs at Vir-Clar helped retain an employee for 14+ years

- Total employment value—wages plus housing plus benefits plus culture—competes effectively against higher-wage alternatives

Practical starting points:

- Calculate your actual turnover cost—most of us significantly underestimate it

- Implement documented onboarding covering mission, safety training, and job descriptions

- Survey current employees anonymously about what would make them more likely to stay

- Track the basics monthly: time-to-productivity, turnover rate, satisfaction indicators

On technology:

- About 8% of robotic milking adopters report zero labor savings due to maintenance demands

- Robots transform labor needs rather than eliminating them

- If you buy a Ferrari but don’t know how to shift gears, don’t blame the car when you’re stuck in the driveway. Robotics require a higher-caliber human, not just a higher-caliber technician.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More

- The Hidden Costs of Turnover: Why Your Dairy’s Biggest Crisis Isn’t What You Think – Stop the bleeding with immediate, low-cost tactics that slash churn from 45% to 15%. This breakdown exposes the invisible production leaks—like SCC swings and calf loss—costing you thousands when veterans are forced into perpetual training.

- Navigate Labor Policy Uncertainty While Your Competitors Automate Past You – Gain a ruthless decision framework for positioning your dairy amid immigration volatility. It reveals how top-tier operations build a permanent competitive “moat” by decoupling production from labor availability, ensuring survival regardless of future policy shifts.

- AI Slashes Feed Costs $31 Per Cow While Your Competitors Pull Further Ahead: The Data-Driven Revolution Reshaping Dairy’s Future – Weaponize your data to capture $31 in annual savings per cow. This guide identifies the specific “make-or-break” AI breakthroughs, from smart camera observation to predictive health algorithms, that are currently widening the industry’s profitability gap.

The Sunday Read Dairy Professionals Don’t Skip.

The Sunday Read Dairy Professionals Don’t Skip.

Every week, thousands of producers, breeders, and industry insiders open Bullvine Weekly for genetics insights, market shifts, and profit strategies they won’t find anywhere else. One email. Five minutes. Smarter decisions all week.

The Sunday Read Dairy Professionals Don’t Skip.

The Sunday Read Dairy Professionals Don’t Skip.