Research shows 7 nutrients can cut calf treatment costs up to 20% when fed in bioavailable forms versus cheap alternatives

Hey folks! Ever stood in the feed store staring at two calf starters with identical 18% protein on the bag, wondering why one keeps your calves thriving while the other has you calling the vet? I’ve been there, scratching my head over why some calves just don’t take off right. Here’s what I’ve learned: the real story’s hiding in the fine print.

Red Flags That Cost Real Money

Before we dive into solutions, let’s talk about what you might already be seeing in your own herd. Watch your records for these warning signs:

- More than 15% of calves are getting scours treatments (according to USDA NAHMS data)

- Pneumonia clusters, especially in vaccinated groups

- Post-weaning growth drops right after transition.

- Dull, rough-coated calves that look “off” without obvious illness.

- Slow recovery from illness, even with proper treatment

If any of these sound familiar, you could be facing hidden nutritional gaps that are draining your time and profits. A sick calf costs real money—not just vet bills but lost growth potential that never comes back.

Every Region Has Its Mineral Curveballs

Here’s the thing—soil and water conditions vary drastically from region to region, and these differences can make or break your calf nutrition program. Some areas battle selenium-poor soils, others deal with iron-rich dirt that contaminates silage during harvest. Then you’ve got sulfur showing up in well water, or molybdenum in forages that ties up the copper your calves desperately need.

One producer I know put it perfectly: “I used to wonder why my neighbor’s calves always looked healthier. Turns out it wasn’t about protein—it was about getting minerals that could actually work with our local soil and water conditions.”

Those pale rings around a calf’s eyes that make them look like they’re wearing glasses? This can be related to a copper deficiency, which is far more common than most of us realize, as copper deficiency is a widespread problem in many areas of the United States and Canada (NASEM, 2016).

The Seven Game-Changers That Actually Matter

Forget chasing protein numbers alone. Research from Penn State, the University of Wisconsin, and extension services nationwide shows these seven nutrients make the real difference between calves that thrive and those that just survive:

Vitamin E: Your Antioxidant Shield

This is your calf’s protection against oxidative stress, especially during periods of stress, such as cold weather or transport. Research shows calves need 220-440 IU per kg of starter feed for real immune benefits—way above basic requirements.

Here’s the catch: Look for natural vitamin E (d-alpha-tocopherol), not the synthetic, cheaper version. Your calf’s body literally can’t use most of the synthetic forms.

Selenium: The Missing Piece

Many regions have selenium-poor soils, so you want feeds hitting the legal 0.3 ppm limit using a reliable source of selenium. Beware the cheap alternative: Inorganic selenium, such as sodium selenite, doesn’t build tissue stores and is instead flushed out. Organic selenium builds reserves that get mobilized during stress—that’s the difference between calves that crash and those that power through challenges.

Zinc: Your Gut Guardian

Strong gut integrity means fewer pathogens getting through. The new NASEM suggests using 75-100 ppm of zinc for stressed calves. Prefer to use more available sources, such as chelated or hydroxy minerals. Red flag alert: Avoid feeds listing zinc oxide—it’s cheap and poorly absorbed. Producers who switch to more bioavailable zinc sources often report improvement on animal performance.

Copper: Easy to Lose, Expensive to Replace

If your water runs high in sulfur or your forages contain high levels of molybdenum, you’re fighting an uphill battle. You need 10-15 ppm copper from chelated or hydroxy copper to overcome the antagonistic effects of these high sulfur/molybdenum minerals. Major warning: Copper oxide is essentially biologically unavailable and worthless—its presence on a feed tag is a major red flag.

Manganese: The Quiet Builder

Critical for bone development in growing heifers. Target 40 ppm from organic or hydroxy sources, especially since iron contamination in feeds can block uptake. High iron levels compete directly with manganese for absorption sites, so bioavailable organic/hydroxy forms help overcome this interference.

Glutamine: The Stress-Buster

This amino acid fuels gut lining cells during transport or weaning stress. Around 1-2% of dry matter intake as rumen-protected glutamine helps calves cope. Form matters: Free glutamine gets degraded in the rumen, so it must be rumen-protected to reach the small intestine where it’s needed.

Arginine: The Circulation Enhancer

Helps immune cells reach infection sites through better blood flow. Supplement at 0.25-0.5% dry matter with rumen-protected forms. Like glutamine, it needs protection from rumen microbes to be effective.

Sponsored Post

Your Feed Tag Cheat Sheet

What to Look For:

- Protein: 18-22% is fine, but don’t obsess

- Vitamin E: 220+ IU/kg from natural sources

- Trace Minerals: Hydroxy or chelated minerals —avoid “oxide”

- Gut Health Boosters: Probiotics, yeast culture, prebiotics.

Questions That Matter:

- “Which specific forms of trace minerals do you use?”

- “How do you account for regional mineral antagonists?”

- “What’s your pellet durability score?”

- “Got any performance data from farms in my area?”

The Bottom Line: Your Wallet Will Thank You

University extension analyses suggest significant returns from proper mineral supplementation, with benefits varying by operation and local conditions14.

Real example: One producer switched to a starter with organic minerals and higher vitamin E. Two years later, he reported his healthiest heifer crop yet—fewer vet calls and better weaning weights.

| Impact Area | Improvement with Organic Minerals | Economic Value (per calf) | Research Source |

|---|---|---|---|

| Treatment Cost Reduction | 20% reduction in scours treatments | $25-40 saved | Multiple university studies |

| Improved Pregnancy Rates | 3-5% increase in conception rates | $150-250 value | Cargill, NAHMS data |

| Weaning Weight Gains | 15-25 lbs additional weaning weight | $30-50 additional revenue | Multiple feeding trials |

| Reduced Mortality | 2-3% reduction in calf mortality | $400-600 loss prevention | USDA mortality statistics |

| Feed Efficiency | 5-8% improvement in FCR | $20-35 feed savings | Feed conversion studies |

| Mineral Supplement Cost | $0.15/day per calf additional cost | $11 annual cost increase | Commercial pricing |

| Net Economic Benefit | $75-150 per calf net return | $75-150 net profit | Combined analysis |

Your Action Plan

This Week:

- Pull your treatment records and look for patterns.

- Check your current feed tags for mineral sources.

- Call your nutritionist with the questions above.

This Month:

4. Test your water and soil for problematic minerals

5. Track starter intake and growth rates closely

6. Consider upgrading to feeds with proven hydroxy or chelated mineral packages

7. Track Results: Monitor intake, average daily gain, treatment rates, and weaning transitions. The numbers will tell the story.

The Hard Truth

No matter where you farm, calves face stress from weaning, weather changes, and the challenges of modern dairy production. Give them the nutritional tools they need—in forms they can actually use—and your bottom line will show the difference.

Don’t let hidden deficiencies steal your profits. Those seven nutrients, properly sourced and formulated for your local conditions, aren’t just nice-to-haves—they’re your competitive edge.

KEY TAKEAWAYS:

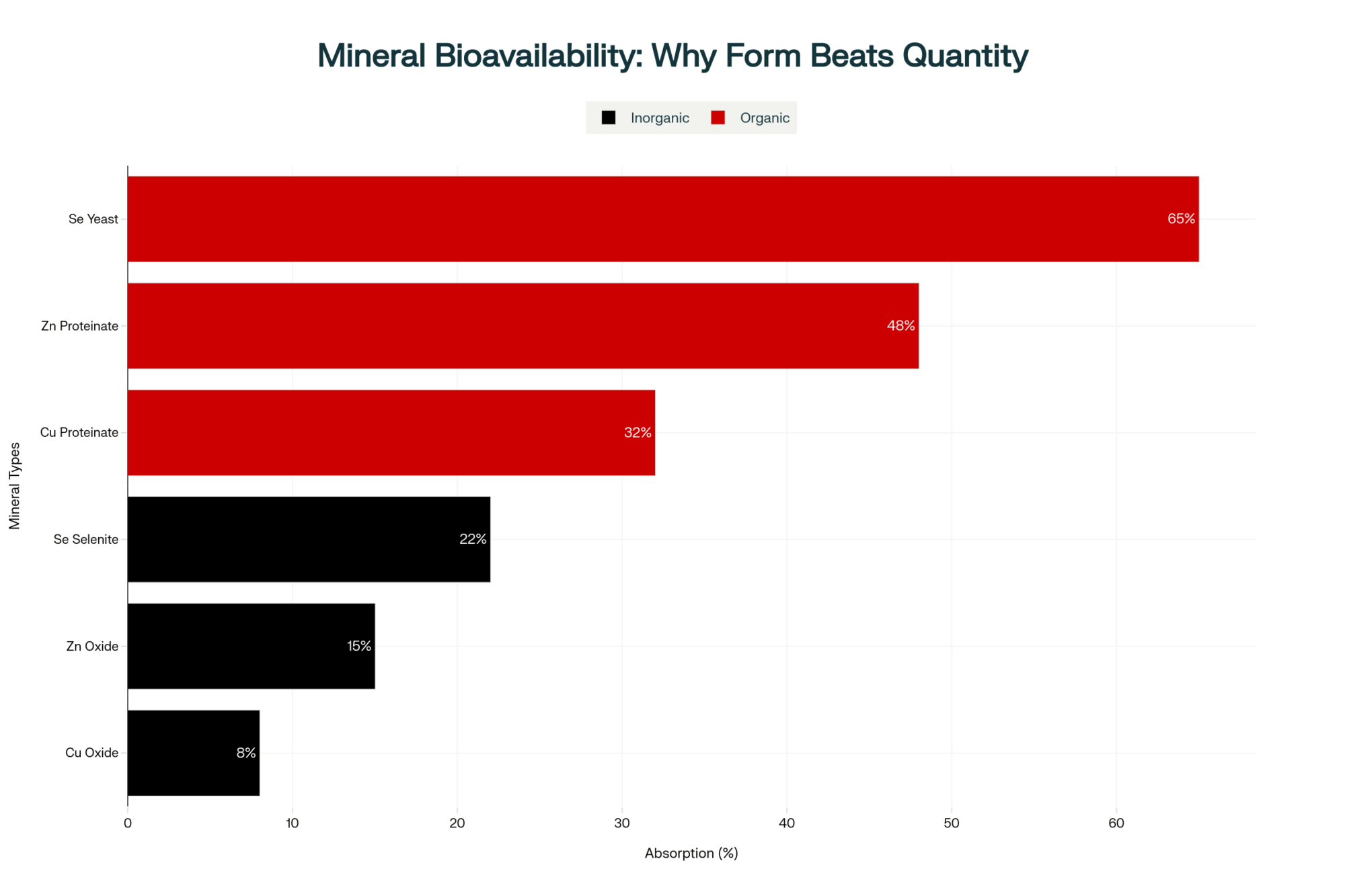

- Bioavailability beats quantity: Organic forms of zinc (proteinate), selenium (yeast), and copper (amino acid complex) deliver 15-30% better absorption than cheaper sulfate or oxide forms, especially when antagonists like iron or sulfur are present in local water or forages.

- Regional customization pays: Producers in high-sulfur water areas or iron-rich soil regions who switch to organic copper sources often see 20% reductions in scours treatments, as organic minerals bypass common antagonistic interactions that block absorption.

- Target the immunity gap strategically: Calves face peak vulnerability between 2-3 weeks of age when maternal antibodies decline, but active immunity isn’t fully developed—optimal levels of vitamin E (220-440 IU/kg) and selenium (0.3 ppm from yeast) during this period strengthen immune response and vaccination effectiveness.

- Form matters more than inclusion rates: Natural vitamin E shows 2-3x greater bioactivity than synthetic forms due to the body’s preferential transport proteins, making it worth the premium cost for operations focused on reducing treatment costs and improving weaning success rates.

EXECUTIVE SUMMARY:

What farmers are discovering is that traditional calf nutrition strategies, which focus on meeting minimum requirements, are leaving money on the table during the most critical growth period. Recent research from leading agricultural universities identifies seven nutrients—vitamin E, selenium, zinc, organic copper, manganese, glutamine, and arginine—that, when delivered in bioavailable forms, can significantly reduce treatment costs and improve weaning performance. The key finding revolves around bioavailability: organic, chelated forms of these nutrients consistently outperform cheaper inorganic alternatives by 15-30% in absorption rates, particularly when dietary antagonists like iron, sulfur, or molybdenum are present. Studies demonstrate that calves receiving optimal levels of these nutrients in bioavailable forms show 20% fewer scours treatments and smoother weaning transitions with less post-weaning growth slumps. Here’s what this means for your operation: by investing in scientifically formulated starters that prioritize nutrient form over just inclusion rates, producers can bridge the critical “immunity gap” between maternal protection and active immunity development. The future of calf nutrition lies in understanding the complex nutrient interactions and antagonisms that vary by region, creating opportunities for producers to tailor their approach to local soil and water conditions.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Sponsored Post

Learn More:

- Revolutionizing Calf Rearing: 5 Game-Changing Nutrition Strategies That Deliver $4.20 ROI for Every Dollar Invested – This tactical article reveals how to prevent scours and improve post-weaning performance through practical strategies like extended colostrum feeding, strategic hay introduction, and probiotics, helping producers achieve a significant return on investment.

- Deconstructing the June Milk Surge: The Management Playbook Your Competitors are Using Now – This piece provides a strategic overview of how savvy producers are leveraging dropping feed costs and market shifts to boost profitability. It offers insights into how you can manage risk and optimize your entire operation to improve your bottom line.

- Beyond Genomics: Is Gene Editing the Next Great Leap for Dairy Cattle? – This article explores the innovative frontier of dairy genetics, including gene editing. It demystifies the technology and reveals how it could accelerate genetic progress and improve animal health, offering a forward-looking perspective on herd management.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!