Some Central Valley dairies have cut water use by 30% while ditching commercial nitrogen completely. Here’s how they’re doing it.

EXECUTIVE SUMMARY: Look, I’ve been watching this subsurface drip thing for years, and it’s finally hitting its stride. The most savvy dairy operators are leveraging SDI to transform their largest cost centers—water and nitrogen—into competitive advantages. We’re talking real numbers here: some California dairies cut applied water by 30% while meeting all their nitrogen needs through lagoon effluent, completely eliminating commercial N purchases on those fields.Kansas State’s research shows the secret sauce isn’t fancy tech—it’s proper filtration and maintenance discipline. Your energy bills also drop because SDI runs at 8-15 PSI, instead of those power-hungry sprinklers. With programs like California’s Dairy Plus offering incentives for water-smart projects, the payback math becomes even more favorable.Globally, precision irrigation is becoming the norm, not the exception—European dairies learned this lesson years ago. This isn’t just about being water-efficient; it’s about building a more profitable, resilient operation. If you’ve got clay loam fields near your lagoon, you’d be crazy not to pilot this on 60-80 acres and see what happens.

KEY TAKEAWAYS

- Slash irrigation water use by 20-30% compared to your current flood setup, especially valuable with 2025’s tight allocations and climbing pump costs; start by identifying your best clay loam fields within 500 yards of your lagoon for maximum impact.

- Kiss commercial nitrogen goodbye on manure SDI fields by timing lagoon effluent to coincide with crop uptake through precise fertigation; obtain quarterly effluent N tests and pair them with tissue sampling at V6/V10 to dial in the perfect application.

- Cut pumping energy costs significantly since SDI operates at 8-15 PSI, versus 30+ PSI for most sprinklers. Run a one-week kWh comparison on your current system to baseline potential savings.

- Layer in cost-share money from programs like Dairy Plus that can cover 50-75% of installation costs; call your local NRCS office this month to get pre-qualified before the next funding cycle.

- Make filtration your religion—automated backflush every 45 minutes, weekly chemistry checks, and seasonal distribution uniformity tests. Skip this discipline, and you’ll turn a 15-year asset into a 5-year headache.

What’s happening on a lot of North American dairies right now—Central Valley, Snake River Plain, the St. Lawrence–Ontario corridor—won’t surprise anyone milking cows. Water certainty’s slipping, nitrogen isn’t cutting deals, and interest rates are still sticky enough to stretch paybacks. If irrigation is just a cost line, it drags. If it steadies forage and trims inputs, it earns its keep.

What strikes me is who’s pushing SDI forward: folks who’ve learned—sometimes the hard way—that filtration, Distribution Uniformity (DU), and disciplined Operations & Maintenance (O&M), not glossy catalogs, decide whether drip actually pays. According to recent work by Kansas State University on maintaining drip irrigation systems and filtration considerations, filtration is the keystone, and clogging is the top failure mode. Getting depth, lateral spacing, pressure, and maintenance right is what protects DU over time (K‑State, MF2178; MF2361).

The SDI Payoff: More Than Just Water Savings

Here’s the thing: drip only pencils when the fundamentals match your soils and water. In hot, dry conditions—and we’re seeing more of them—Subsurface Drip Irrigation (SDI) reduces evaporation and runoff compared to flood irrigation. That’s exactly when overhead can fight wind and heat, and surface sets lose at the edges. It’s the edge producers chase in July and August when every drop counts.

And we’ve got current, field-level reporting to back this up. A Central Valley dairy that maintained commercial forage yields while cutting applied water and, on those SDI fields, met nitrogen demand with lagoon effluent—no commercial N on those blocks—under tight filtration and scheduling across multiple seasons. What’s particularly noteworthy is how they’ve maintained this performance consistently.

Sustainable Conservation’s Manure Subsurface Drip Irrigation (MSDI) Summary Evaluation documents similar results. When you pair solids separation with sand-media filtration (automated backflush), protective screening, and chemical injection to manage biofilm and mineral scaling—backed by operator training—dairies can replace a meaningful portion of commercial N while improving nutrient capture and reducing losses. No yield sacrifice required (Sustainable Conservation, 2024).

On the ground, most producers aren’t flipping their entire ranches. That would be… well, crazy. A practical start has been 40–80 acres where the odds stack in their favor: clay or silt loam for better lateral water movement, straightforward plumbing to the lagoon if MSDI is in scope, and a water price or allocation that rewards precision. Schedules often lean toward frequent, short sets to hold the root zone steady—small swings, fewer stress dips. In alfalfa, that tightens cutting windows and helps protect quality. In corn silage, it reduces late-July stress that quietly shaves tonnage and feed value. It’s not flashy. It’s consistent.

The Catch: Where Drip Systems Fail (And How to Avoid It)

Kansas State’s materials are blunt about this: filtration is the keystone. Undersize it, skip chemistry, or let backflush cycles slide, and clogging starts quietly and ends expensively (K‑State, MF2178; MF2361). The guidance also makes it clear that maintenance schedules—such as backflushing, chemical dosing, and inspection—are integral to the design, not an afterthought.

In terms of hydraulics and energy, SDI commonly operates at lower pressure than many sprinkler packages—often 8-15 PSI—which can reduce pumping energy if the Total Dynamic Head (TDH) and your well characteristics cooperate. Actual savings depend on site conditions and should be metered, not assumed (K‑State, MF2178; MF2361). Here’s the reality check, though: soils matter. Sandy ground can work, but it typically requires closer lateral spacing and tighter scheduling, which pressures economics. Run the math before tying up big acres.

Rodents and pests don’t read manuals; line protection and inspections are part of ownership. And expect a labor shift: less time moving sets, more time monitoring flow, pressure, Electrical Conductivity (EC), and DU. Different skills. Not less work—just smarter work. This is becoming more common as operations get more sophisticated.

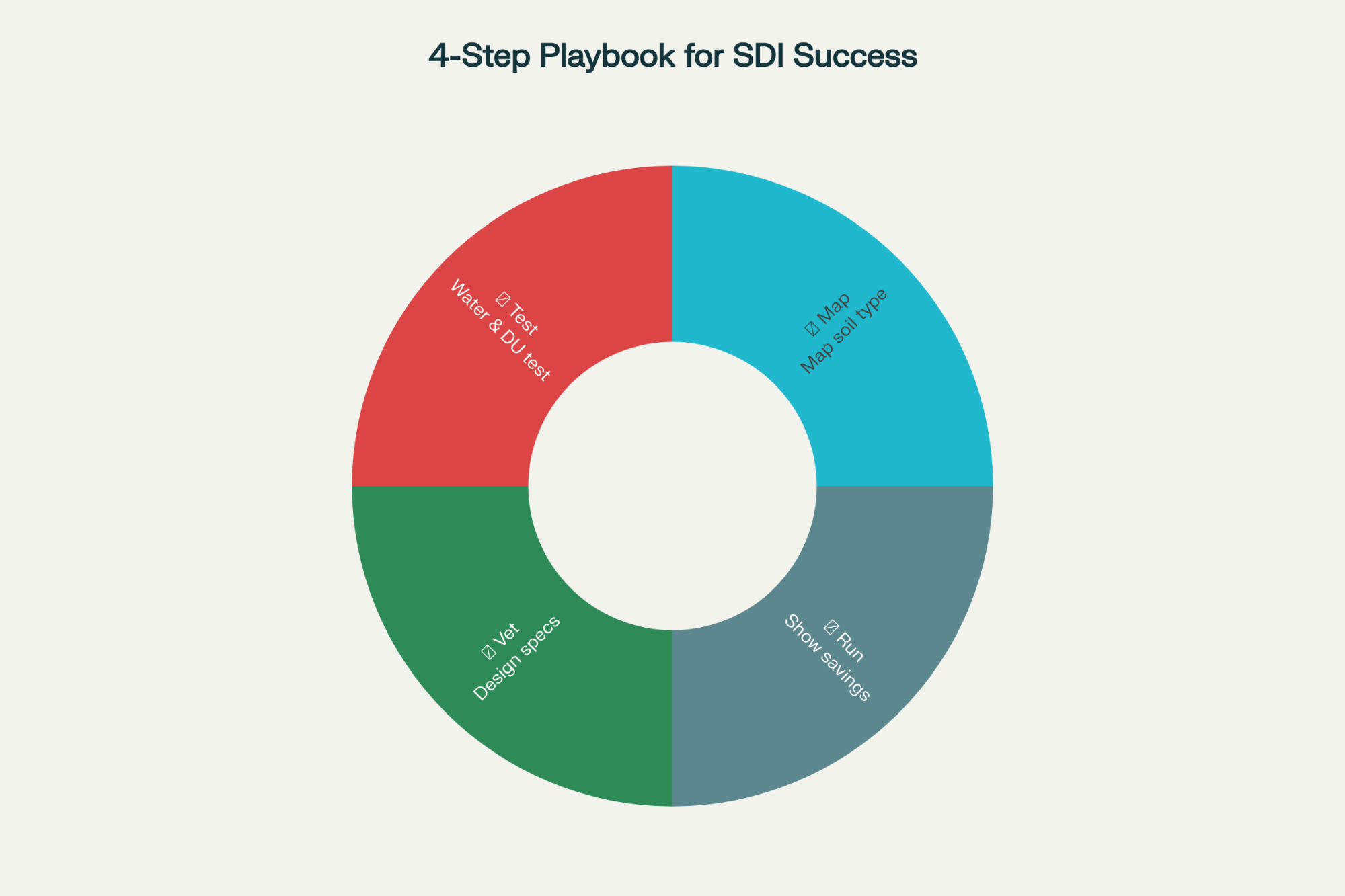

The Playbook: Your First 80 Acres

Map Your Ground First

Target clay and silt loam fields with the highest water cost or strictest nutrient limits. If MSDI is planned, choose acres near the lagoon. This is where SDI’s stacked benefits—water reduction, N displacement, potential energy savings, and incentives—have the best chance to outpace capital cost.

Test Your Water (and Effluent)

Before design, commission two baselines. First, a water-quality panel covering solids, EC, hardness, iron, and biological indicators to size filtration and chemical injection properly (K‑State, MF2361). Second, run a DU test on your current system using NRCS/extension protocol to benchmark distribution and build a measurement culture for the new system.

Vet the Design Like Your Money Depends on It

Sanity-check vendor specs against K‑State parameters. Dripline depth: aim for 12–18 inches in corn and 8–12 inches for alfalfa. Lateral spacing: match to soil hydraulics—wider in clays and silt loams, closer in sands. Emitter flow: target 0.5–1.0 gph, depending on soil intake rates and uniformity goals. Operating pressure: ensure the design is low and stable, and confirm the strategy for pressure regulation and air/vacuum relief is robust (K‑State, MF2178; MF2361).

For MSDI, follow Sustainable Conservation’s framework, which includes solids separation/pretreatment, sand-media filtration with automated backflush, protective screens, and chemical injection to control biofilm and precipitation, supported by operator training and logs (Sustainable Conservation, 2024).

Run the Numbers (Stack Those Benefits)

With 2025 financing still elevated, payback stretches unless multiple benefits are realized. Here’s what to stack: Water savings from reduced applied volume relative to your current system, especially valuable under tight allocations or high pumping costs. Nitrogen credits calculated from displaced purchased N by fertigating with lab-verified lagoon effluent timed to crop uptake—validate with in-season tissue tests. Energy reduction metered through pump logs before and after; lower operating pressure may reduce kWh/acre if your TDH cooperates. Incentive programs, such as California’s Dairy Plus, which may fund projects that improve groundwater and nutrient management when proper monitoring is documented (CDFA, 2024; CMAB, 2025).

Do a modest stress test on a 70-acre pilot: raise water price 15%, N cost 10%, energy 5%. If the pilot remains cash-positive on an annualized basis, scale to similar soils. If not, you’ve learned which lever—water, N, or incentives—needs to move.

Looking Ahead: What’s Coming Down the Pike

What’s fascinating is how SDI technology continues to evolve. Self-flushing driplines are reducing maintenance requirements. Smart emitters with flow regulation and monitoring are becoming more common. We’re even seeing biodegradable mulch films for enhanced moisture conservation in some operations. The integration with precision ag platforms—real-time monitoring via smartphone apps, automated fertigation based on soil sensors, weather-based scheduling—is making SDI less of a “set it and forget it” system and more of a dynamic management tool.

Based on industry observations, dairies achieving the best results treat SDI as both a data collection system and an irrigation method. They’re logging everything: flow rates, pressure variations, EC readings, DU tests, energy consumption. This data-driven approach is what separates the success stories from the expensive lessons.

The Bottom Line: Boring Is Profitable

SDI isn’t a magic button, and it’s not for every acre. However, it’s a precision platform that, when engineered to Kansas State’s standards and run with the MSDI lessons Sustainable Conservation has documented, can turn water and nutrient uncertainty into steadier forage and lower purchased inputs. Recent intelligence suggests that real dairies are indeed doing exactly that under pressure from the Central Valley.

The dairies that pilot thoughtfully, measure relentlessly for two full seasons, and scale only where the numbers hold… they’re the ones turning SDI from “interesting tech” into a dependable business tool. The winners aren’t the ones with the fanciest hardware. They’re the folks with the cleanest filters, the tightest DU, and the most boringly consistent schedules.

Not glamorous. Profitable.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More

- Unlocking Hidden Profits: A Dairy Farmer’s Guide to Advanced Nutrient Management – This guide provides a farm-wide strategy for manure and nutrient planning. It perfectly complements the SDI article by showing how to maximize the value of lagoon effluent before it even hits the dripline, ensuring your fertigation plan is profitable.

- The Sustainable Dairy Farm: Turning Green Practices into Black Ink – Explore the market forces making sustainability a key driver of profitability. This piece connects the on-farm water and nitrogen efficiencies gained from SDI to the broader business strategy of building a more resilient and valuable dairy operation for the future.

- Don’t Feed the Landfill: How Feed Efficiency is the Next Big Genetic Win for Dairies – After optimizing how you grow forage with SDI, discover how to optimize how your cows consume it. This article reveals how selecting for feed efficiency genetics creates a powerful one-two punch, lowering costs from the soil to the silo.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!