Archive for Management – Page 56

Missed udder infections and subsequent missed treatments are costing global dairy farmers a massive $10 billion a year.

It is, however, the smaller family dairy farms that are being hit the hardest with the financial burden as udder infection detection rates in these situations can be low.

A Canadian company hopes to address the issue with a new detection system.

EIO Diagnostics has developed a new system that scans udders in the parlour, either via a mounted scanner in robotic milking systems or a hand-held device and relays the images to a screen where infections can be identified easier.

EIO claim its solution detects these infections sooner and cheaper, than any other approach on the market.

EIO uses a technique known as multispectral imaging, which detects udder abnormalities as they form.

Animals that are affected by harmful pathogens, even at somatic cell count (SCC) levels generally considered sub-clinical, can then be identified by farmers.

Being able to identify a Staphylococcus aureus infection, even when a standard SCC test is showing levels below 200,000 SCC, gives farmers an effective tool for in-creasing herd health and minimizing production losses.

The hand-held device, which is about the size and shape of a small tablet, can assess health of an udder in less than one second.

Used in bigger automated milking parlours, the mounted device identifies and monitors cows as they enter the milking stall or robot. It integrates with DeLaval VMS or Lely Astronaut robotic milkers and can also be integrated with automated feeders, leveraging existing animal identification systems.

The brains behind the detection system is Cory Spencer, who started EIO in the barns of his Happy Goat Cheese Company in British Columbia’s Cowichan Valley.

Spencer, a software developer and goat cheese maker, had experienced a mastitis problem with one of his 100 goats.

Along with neighbour Damir Wallener, a solution was brought to life this spring and summer.

Wallener, the chief executive officer of EIO, said they are receiving a lot of interest.

“From the intense interest we are receiving from actual dairy farmers, the answer has to be no, there are no similar systems on the market.

“There are automated SCC and electroconductivity devices available, but they share the problem of trying to identify udder infections by measuring something indirectly related to the actual infections.

“No other product also works with dry cows or pre-calving animals that don’t regularly pass through the milking parlour,” he said.

The EIO Diagnostics system is being tested in several commercial dairy barns on Vancouver Island, using goats and cows. The company is also preparing for its first large scale deployments, one in New Zealand and one in Wisconsin.

EIO say it prices the system on a service model rather than individual hardware sales and each system will differ on the number of scanners required.

“EIO manages all the hardware, software, updates and maintenance, for a fixed price, with no surprises. For goat dairies, the pricing is $3 per month, per goat. For cows, it is $5 per month, per cow. From the farm’s perspective, by reducing per-animal lab tests, or saving just one bulk tank from being dumped, the service pays for itself very quickly.”

Once the device visualises an udder, it takes a number of measurements from various parts of the spectrum. These are run through a complex mathematical model, generating a pass or fail signal.

“This takes less than a second,” said Wallener. “The measurements are also pushed to EIO’s software cloud, where they are combined with all the other imaging done at all the other barns.

“Over time, improved models are pushed back down to the devices, allowing every farm to learn from what is happening on every other farm.

“The system can send emails, text messages, and it can use messaging apps like Slack or update a cloud-based dashboard. Basically, any internet-dependent communication channel is either supported, or easy for us to add.”

During the next few months, EIO is working with a university dairy science program and hopes to publish results showing how well its detection matches up with actual pathogen tests, said Wallener.

Source: The Western Producer

A study of the UW dairy herd looked at 141 lactating Holstein cows. (Courtesy of UW-Extension)

A study of the UW dairy herd looked at 141 lactating Holstein cows. (Courtesy of UW-Extension)MADISON — Zoey Rugel: New research on the estrous cycle in cows. Today, we’re visiting with Paul Fricke, Extension specialist in dairy cattle reproduction, Department of Dairy Science, University of Wisconsin-Madison/Extension, in the College of Agricultural and Life Sciences, and I’m Zoey Rugel. So, Paul, tell us about some current research you have going on.

Paul Fricke: One of the most recent projects that we’ve worked on had to do with looking at when cows return to estrus after you inseminate them. A lot of people in the industry have bought these heat detection systems, and, so, what they’ll often notice is that non-pregnant cows don’t all come into estrus at 18 to 24 days—it’s more like 18 to 32 days. So, we have a lot of cows with these extended inner estrus periods and that kind of peaked our interest as to what was going on during this time period.

Click here to listen to the podcast.

Zoey Rugel: Tell us about the study. How was it conducted?Paul Fricke: Yeah. So, what we did is we worked in our UW herd here, which is right on campus, sitting up at Arlington. We took 141 lactating Holstein cows, we set them up for a timed insemination. Then what my graduate students were doing is that 3 times a week they would ultrasound the ovaries to see what the CL looked like. They would take blood samples to look at progesterone. So, we could really define what was happening with the corpus luteum during this time and what was going to happen as far as when the CL regressed.

Zoey Rugel: What did you end up finding?

Paul Fricke: 57 of those 141 cows were pregnant, and pregnant cows are really kind of boring when you look at them, because progesterone comes up, the embryo signals the maternal system that the cow is pregnant, and they just maintain that CL. What was really interesting was the non-pregnant cows. There were 80 cows that were diagnosed open on day 32 and only about half of those cows, 55 % of them, read the textbook. They would’ve regressed their CL and come back into heat about that 18 to 24 day time period, but there were 23.7% of those animals that had an extended luteal phase, and what was most interesting was that there was about 21.3% of the cows that never regressed their CL during this time period, but did not have a CL when we did the pregnancy check on day 32. So, those cows would never have shown an estrus during that time period.

Zoey Rugel: So, what’s the bottom line?

Paul Fricke: So, the primary reason that this happened—the other aspect of this experiment—is we pulled blood samples from those cows on day 25 and day 32, and we can measure a pregnancy-associated glycoprotein. This is a protein that is secreted by the pregnancy, and over half of the cows that failed to regress their CL had the presence of this pregnancy-associated glycoprotein, indicating that they were pregnant long enough to keep them out of estrus, but then they subsequently lost their pregnancy. So, it’s just another way to look at this really early pregnancy loss that would’ve gone unnoticed if you just do a pregnancy check, but, in fact, a lot of these cows are getting pregnant and having these extended luteal phases and it really changes the dynamics of when these cows are coming into heat.Zoey Rugel: We’ve been visiting today with Paul Fricke, Extension specialist in dairy cattle reproduction, Department of Dairy Science, University of Wisconsin-Madison/Extension, in the College of Agricultural and Life Sciences, and I’m Zoey Rugel.

Feed to maximize milk components

The success of an operation depends on dairymen making correct decisions on an animal-by-animal basis.

“The challenge is to find the cow of interest that needs something special,” said Dave Barbano, professor in the Department of Food Science at Cornell University. “Then you need to make a decision and take the correct action.”

Milk production is the sum of the performance of all individual cows, Barbano said during a Hoard’s Dairyman webinar.

“We need to condense the data down to information that helps farmers make decisions and not be buried in a sea of numbers,” he said.

Over the last couple of months, Barbano said, a cow of interest study was completed that included 170 farms from across the U.S. Both bulk tank and individual cow samples were evaluated at several locations.

“We are getting a much better understanding of how to use milk fatty acid data for whole-herd management and milking group diagnostics,” Barbano said.

“We need high-frequency data, and we need to develop hardware and software to integrate this milk testing approach into the milking system on a continuous basis from every cow,” he stressed.

“The first thing that came to light when we started researching five years ago was a fairly strong correlation of the de novo fatty acids with the bulk tank fat test,” he said. “That seemed to tell us something about how well the cows were digesting forages.”

Management Tools

The researchers use an infrared milk analysis machine.

“It creates statistical models to extract information out of the fingerprint of the milk to measure fatty acids,” Barbano said. “It is a direct measurement of milk, there are no chemicals involved, the milk goes through the machine and we get answers.”

For the study in 2014, the researchers selected 10 low de novo and 10 high de novo herds of both Holstein and Jersey farms. To evaluate the farms, they took feed samples, farm management information, the amount of milk produced per cow and what they were doing to make this happen.

In 2015, the study was repeated with 40 Holstein farms that were either high or low de novo.

“The high de novo Holstein farms had nearly 4 percent fat compared to the low farms at 3.6 percent fat, and for the Jersey farms, the high de novo farms were nine-tenths of a percent higher in fat and half a percent higher in protein, which is huge in terms of cheese yield,” Barbano said. “And the high de novo herds produced more milk per cow.”

As a result, there was a gross income difference of $30,000 for the higher components of a 100-cow herd, he said.

The following year, for only the Holstein herds, the higher de novo herds had two-tenths of a percent higher fat and one-tenth higher protein.

“There was quite a difference in the milk price, so the higher de novo herds had nearly $15,000 difference in gross income,” Barbano said.

“Understanding how to influence components and get them up while not losing milk volume is really something to push better profitability on farms,” he said.

Source: AgriNews

To qualify for the PGH award, herds must participate in the TriStarSM production records program at the Premier or Deluxe levels, and participate in the Holstein type classification program. Herds must have at least 20 cows of 87% RHA or higher.

All eligible herds are automatically evaluated annually and the PGH recognition is awarded to the 500 herds with the highest average TPI for females in the herd, both young and mature.

The TPI average range for the top 500 herds in 2017 was 1957 to 2450. The highest average TPI herd in this year’s PGH honoree group was David, Patrick & Frank Paul Bauer of Sandy-Valley Holsteins in Wisconsin, with an average TPI of 2450.

Thirty-one herds received the award for the first time this year: Alfalawn Farm, Wis.; Matthew P. Berning, Ill.; Big De Farms LP, Calif.; Andrew & Sarah Birch, Vt.; Mark Carviou, Wis.; Double W Dairy, Colo.; Double-Take Dairy LLC, Wis.; El-Vi Farms LLC, N.Y.; Ferncrest Farm, Pa.; Mrs. J. B. Fiscalini & Son, Calif.; Donald Fisher Farms, Inc., Ohio; GenoSource, Iowa; Kylie Konyn, Calif.; Lochmead Farms, Ore.; Jeremy D. Martin, Pa.; James Mast, Pa.; Bird City McCarty Family Farms LLC, Kan.; Rexford McCarty Family Farms LLC, Kan.; Scott City McCarty Family Farms LLC, Kan.; Jeffrey J Orr, Pa.; Osborne Family Farm LLC, N.Y.; Roaring Creek Farm, Pa.; Brent D. Robinson & Brent Moyer, Mich.; Patrick Slattery, Wis.; United Vision Dairy LLC, Wis.; University of Wisconsin, Wis.; VDS-Farms, LLC, Mich.; Russ Warmka, Wis.; Darrell Gene Wright, N.C.; W-R-L Daniels Farm LLC, Mich.; and Cleason N Zimmerman, Ohio.

Twenty-three herds have received PGH honors all 27 years the award has been given: Floyd & Lloyd Baumann & Fred Lang, Wis.; Bomaz, Inc., Wis.; R. Paul Buhr, Jr., Wis.; De Su Holsteins LLC, Iowa; End Road Farm, Mich.; Brian & Wendy Fust, Wis.; Steven G. Holte, Wis.; Jaloda Farms, Ohio; Randy W. Kortus, Wash.; Roger & David Latuch, Pa.; Lirr Farm, Wis.; Nordic-Haven Holsteins, Iowa; Gaylon, Gary & Steve Obert, Ill.; Mark P. Paul, Wis.; Regancrest Holsteins, LLC, Iowa; Darrell Richard, Ind.; Alfred & Mark Schmitt, Minn.; Scott Seward, Wis.; Stelling Farms, Inc., Minn.; Veazland Farms, Maine; Walhowdon Farm, Inc., N.H.; Wardin Bros., Mich.; and Welcome Stock Farm, LLC, N.Y.

View the complete list of 2017 Progressive Genetics Herd Award honorees at www.holsteinusa.com/awards/herds.html.

Holstein Association USA, Inc., www.holsteinusa.com, provides products and services to dairy producers to enhance genetics and improve profitability–ranging from registry processing to identification programs to consulting services.

The Association, headquartered in Brattleboro, Vt., maintains the records for Registered Holsteins® and represents approximately 30,000 members throughout the United States.

I see a lot of commonality in these unfortunate situations. They often fall into four main categories of gut aches, namely: nutritional scours, abomasum bloat, rumen acidosis and hay belly. In order to take corrective action, I recommend a return to a simple calf feed and management program.

A large part of this problem stem from feeding pre-weaned calves as if they were mature dairy cows.

A newborn baby dairy calf starts off with a small, undeveloped rumen without an established microbe population (it gets this from its surrounding environment later on). It must rely upon a few selected enzymes released by its own abomasum and small intestine in order to break down simple-type essential nutrients, which are only found in milk such as casein and other milk proteins, lactose sugar, and saturated fats.

By four weeks of age, the calf’s abomasum and small intestine become a little more developed. Now, the calf’s rumen has a variety of new digestive enzymes as well as a limited type of microorganisms, which together can convert simple starches/sugars from grain-based calf starters into volatile fatty acids (VFA) which are absorbed across the rumen wall.

It is these absorbed VFAs, particularly butyric and propionic acids, which stimulate the absorptive tissue lining of the young calf’s rumen to become very active — rumen papillae elongate and the rumen walls thicken. The whole rumen grows, and the small calf is on its way to become a true ruminant.

The results of unsound programs

Rather than promote steady ruminal development in six- to eight-week-old dairy calves; many askew and unsound pre-weaned calf-feeding programs do just the opposite and cause the following digestive upsets:

1. Milk and milk replacer scours: It is frequently seen as bright yellow, cream-coloured or nearly white liquid; all signs that a recently consumed milk or milk replacer meal was poorly digested. Not only does poor milk digestion lead to poor absorption of essential nutrients that the calf requires to live and grow, but unabsorbed nutrients left in the calves’ gut tend to draw retained water from the calf’s tissues, which amplifies scouring and life-threatening dehydration.

For example, I often see milk replacer scours in calves when producers mix milk replacers at a rich 150 grams of powder per litre of solution, rather than 130 grams per litre of solution, which is the natural dry matter content of whole cow’s milk.

2. Baby calf rumen acidosis: It has been proven that pre-weaned dairy calves can get acidosis eating too much grain-based calf starter, much like a milking cow that eats too much grain. For example, the University of Tennessee (1998) fed a conventional calf starter pellet formulated with corn and other common feed ingredients to a group of milk-fed calves from one week to 12 weeks of age. As a result, these researchers found that SARA (sub-clinical rumen acidosis; depicted when pH in a cow’s rumen falls below 5.8) was reported in experimental calves at two weeks of age.

Similarly, some producers have told me that when they feed more than 3 lbs. of texturized calf starter or on a free-choice basis found that many calves seem to go off feed after a couple of days of vigorous eating of calf starter — a possible sign of acidosis.

3. Abomasum bloat: This is caused by the rapid proliferation of clostridium perfringens that produces a severe buildup of excess gas in the abomasum of pre-weaned calves. From the outside, there is severe distension on the right side of the calf, while similar ruminal bloat is distension on its left side.

Unfortunately, abomasum bloat seems to occur suddenly, and the calf often perishes before any treatment can be administered. Some research suggests that feeding higher concentrations of milk replacer than 130 grams per litre of mixed solution that supply a high level of lactose sugar to the bacterium, which may lead to a high incidence of abomasum bloat.

4. Hay belly: Many good studies prove that feeding straw or other low-quality forage for its “scratch factor” is a myth. Virginia Tech (2010) showed that two- to four-month-old calves fed a textured grower diet had similar growth to calves that were fed texturized feed plus added wheat straw. The wheat straw group did weigh 21 lbs. heavier at the end of the test, but it was attributed to 21 lbs. of gut fill and water. Similarly, I find that many calves fed in this manner suffer from semi-impaction and/or bloat — literarily walking balloons on sticks for legs.

Recommendations

To avoid each of these four gut ache or indigestion problems, I strongly recommend following a simply nutritious calf-feeding program.

Make sure colostrum is fed to newborn calves and afterwards provide whole milk or a milk replacer at 2.5-4.0 litres per calf per feeding (twice a day) at approximately the same times (a.m./p.m.) each day. Subsequently, start to feed a high-quality grain-based calf starter to calves at two to three weeks of age. Avoid feeding any forage until after weaning. Finally, assure that clean water is provided in addition to all whole milk or milk replacer feedings.

Source: Grain News

The Royal College of Veterinary Surgeons (RCVS) said that vets were harming pets and livestock by placing faith in “unproven claims” rather than traditional methods.

More than 3,000 vets have signed a petition expressing concerns about the use of homeopathic treatments.

Chris Tufnell, RCVS senior vice-president, highlighted the popularity of a homeopathic remedy called nosodes where sugar-coated pills made from diseased matter from a sick animal are used instead of vaccinations.

“I have seen dogs die from completely preventable conditions such as parvovirus, which is extremely unpleasant and preventable,” said Mr Tufnell. “It’s entirely unnecessary.” He added that pets had been left in “unacceptable” pain because their owners used homeopathic medicines rather than painkillers.

Homeopathic treatments have been advocated by the Prince of Wales and others although clinical trials have shown that they offer no benefit beyond the placebo effect, where a patient’s belief that a treatment will work may alleviate some symptoms. There is little evidence that the placebo effect works in animals.

This month, the RCVS agreed a policy statement which concluded that there was no “recognised body of evidence” for homeopathy. “Furthermore, it is not based on sound scientific principles,” it said. The statement continued: “To protect animal welfare, we regard such treatments as being complementary rather than an alternative to treatments for which there is a recognised evidence base or which are based in sound scientific principles.

“It is vital to protect the welfare of animals committed to the care of the veterinary profession and the public’s confidence that any treatments not underpinned by sound scientific principles do not delay or replace those that do.”

The statement has been supported by the British Veterinary Association which said that “complementary and alternative treatments not based on sound scientific principles or evidence could have detrimental consequences for animal health and welfare”.

However, the British Association of Homeopathic Veterinary Surgeons said that it was “deeply disturbed” by the RCVS policy and described it as a “biased and ill-judged viewpoint”. A spokesman said that pet owners used complementary and alternative medicines when conventional treatments did not work or when they produced unwanted side-effects.

The Prince of Wales claimed last year that he treated cows and sheep on the farm at his Gloucestershire estate with homeopathic remedies “as part of a programme to reduce the use of antibiotics”.

The RCVS statement follows a petition calling on the organisation to ban veterinary surgeons from prescribing homeopathic treatments, which attracted more than 3,300 signatures.

The petition, set up by Danny Chambers, an equine vet in Devon, warned that allowing the use of such therapies could lead to “unnecessary suffering or death” because of the danger of them being used instead of orthodox treatment. “It would be devastating for a dairy farm that went out of business because homeopathic treatments failed to control an outbreak of mastitis [mammary gland infection],” he wrote.

Source: The Times

Since it’s introduction, The Dairy Margin Protection Program has received a great deal of criticism, but an FSA director says farmers are still signing up for it.

Sandy Chalmers who is with the Wisconsin Farm Service Agency says, “We are seeing people come in to sign up, and they’re signing up across the board on the coverage levels, so even though there was considerable concern expressed over the years about the program, people are still signing up, and maybe not at the levels they had in the past.”

Chalmers explains that producers can get out of the program if they wish. “If they want to opt-out of MPP Dairy, just do nothing. You don’t have to call your county office. You don’t have to stop in. You don’t have to do anything.”

Chalmers says producers can opt out of MPP, LGM Dairy or both if they choose to. Producers that want MPP coverage must sign up by Friday, December 15th.

December temperatures have been unusually warm, but we can expect to soon be reminded of the realities of Cache Valley winters. Energy requirements for animals increase as air temperatures decrease, and in Cache Valley, January is often the coldest month of the year. As such, livestock and dairy producers must pay close attention to the needs o f their animals. Adequate housing and proper nutrition are the major considerations for all animals, but this is especially true for baby calves. Knowing how valuable calves are, successful producers will give careful attention to every detail.

December temperatures have been unusually warm, but we can expect to soon be reminded of the realities of Cache Valley winters. Energy requirements for animals increase as air temperatures decrease, and in Cache Valley, January is often the coldest month of the year. As such, livestock and dairy producers must pay close attention to the needs o f their animals. Adequate housing and proper nutrition are the major considerations for all animals, but this is especially true for baby calves. Knowing how valuable calves are, successful producers will give careful attention to every detail.

“Within the dairy industry there is a high percentage of contact time between animals and human beings on a daily basis, and like in other high-risk jobs, employees need to be aware of their surroundings at all times and implement safety practices and procedures,” Erickson said.

So, what type of injuries can happen when working on a dairy? Erickson said typical animal-related dairy injuries are the result of being stepped on, kicked, fallen on, crushed by cows, mauled by dairy bulls or gored by animals that have not been dehorned.

Safety reminders

Flight zone: Because dairy cattle have binocular vision, meaning they are able to see all the way around themselves, except for a small blind spot at the nose and rear of the animal, it is important to know how to approach an animal, Erickson said. Approach the animal from the side, while using verbal cues such as speaking softly, that will minimize spooking an animal.

Understand how to use the “flight zone” in a proper manner to help facilitate moving an animal in a desired direction. The flight zone is often referred to as an animal’s “personal space.”

Noise sensitivity: Cattle are very sensitive to noise and a higher frequency of noises than humans. Yelling causes stress to animals and can make them more difficult to handle, Erickson said. Staying quiet and calm will help minimize these reactions. Additionally, unexpected loud noises such as banging gates, loud exhaust from air cylinders, etc., may startle animals.

One way to help condition cattle is to keep a radio playing in the background at a low level in the barn to help reduce the reaction to strange, sudden noises. This can be a very effective tool when training cattle for show and being in fair situations.

Isolation: Cattle are herd animals, so isolation may cause an animal to be nervous, stressed or agitated. When working with an animal, having another companion animal near will help keep the animal being treated calmer.

Past experiences: Cattle do remember painful or frightening experiences. So, if an area of the barn brings up unpleasant memories for a cow, such as pokes, slipping or rough handling, they may become unwilling to cooperate when they return to that same area.

Warning signs: Good livestock handlers should be able to watch for warning signs of an agitated animal. Cattle will react with a raised head or pinned ears, raised tails, raised hair on the back, exposed teeth, excessive bawling, pawing the ground and snorting.

Proper livestock handling reminders

Appropriate livestock handling behaviors include:

1. Use slow and deliberate behavior.

2. Avoid loud noises or quick movements.

3. Do not prod an animal when it has no place to go.

4. Gently touching animals will have a more favorable response than shoving or bumping them.

5. We need to respect animals and not fear them.

6. Intact male animals, especially dairy bulls, should be considered potentially dangerous at all times, and proper equipment and facilities should be made available to assure the safety of handlers.

7. Breeding animals tend to become highly protective of their young, especially when giving birth.

8. Animals will defend their territory, and this should be kept in mind at all times, given the size, mass, strength and speed of an animal.

9. Cows will typically kick forward and out to the side and also have the tendency to kick toward the side where they have pain from inflammation or injuries. Thus, if a cow has a single quarter with mastitis, approach her from the opposite side of the non-affected udder when examining her, or utilize proper restraint to avoid being hurt.

Source: Feedstuffs

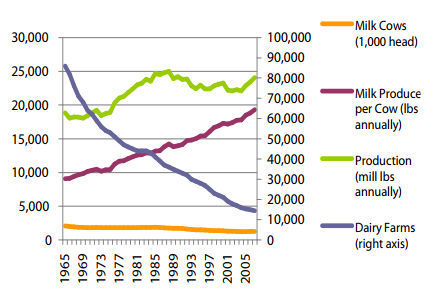

Many Wisconsin dairy farms now hire employees versus family labor alone. Wisconsin dairy farmers have increased herd size to pursue a strategy of increased production to make ends meet or increase farm income. Tighter farm budgets may also compel members of farm families to seek off-farm work for a secure income base and/or health insurance. Additionally, farm families (like U.S. families in general) are declining in size, spouses and farm children increasingly seek off-farm careers and the average age of Wisconsin dairy farmers is increasing. These trends further lead to the need for hired employees.

Farmers interviewed in UW surveys reported difficulties finding U.S.-born workers willing to fill dairy farm jobs. Farmers said young people in rural Wisconsin have little desire to work on dairy farms, and that it is hard to find U.S.-born people willing to work long hours, night shifts and weekends.

“So as our last two children entered high school, and I realized that soon I would have no family labor to rely on, we moved our farm to all hired labor. I have not been able to hire an American citizen since 1997. I have tried! The way I see it, if we didn’t have Hispanics to rely on for a workforce, I don’t believe I could continue farming,” said one Wisconsin dairy farmer.

Farmers insist that this demographic shift in the dairy labor force is not an effort to undercut the local wage rate, but instead to find ‘reliable’, hard-working, year-round employees willing to work the demanding hours and do the necessary tasks.

In the words of another Wisconsin dairy farmer, “It’s not about Hispanics. It’s about who wants to do the job. We don’t get a lot of applications from people who want to do the job. There are lots of myths out there… in our area you hear from some people that these people [Hispanics] are taking jobs away. But the fact of the matter is that there is nobody here who will work for those wages. The folks in ag cannot afford to pay those wages.”

There is no doubt that in recent years, residents have fled rural counties in Wisconsin, and many of them are young people. Between 2000 and 2010, Wisconsin’s population grew by six percent, but more than a quarter of Wisconsin’s 72 counties lost population. Most of the losses in Wisconsin were in rural areas where the main industry is agriculture. Jackson County lost seven percent of its population during that time frame.

Immigrant workers and their families bring their skills and ambitions into Wisconsin, breathing new life into the state’s rural communities. Hired workers, regardless of origin, boost the strength of the state’s dairy industry and also enable dairy farmers to take vacations and have some time off during the day to attend their children’s sporting events or other community activities.

Although immigrant employees are a crucial component of the economic viability of dairy farms, the employer-employee relationship is fraught with legal and economic vulnerabilities.

Some immigrant farm workers lack legal authorization to work and live in the U.S., which exposes both employers and employees to increased risk, threatening agricultural investment. Wisconsin’s growing reliance on immigrant labor presents challenges, yet can also serve as a call to develop programs and policies that will both improve conditions for immigrant employees and families, as well as to maintain a dependable farm labor force.

For the benefit of the families who farm and Wisconsin’s dairy industry, a secure dairy farm labor force is necessary. This means we must honor immigrants as human beings: members of the communities in which they live and to which they contribute; possessing dreams and ambitions; and deserving a full array of human rights and freedoms.

Source: La Crosse Tribune

Peritonitis refers to the inflammation or infection around the peritoneum which is the inside lining of the abdomen. Any infection involving the abdomen receives the nondescript description of peritonitis. This could be an infection around the intestines, stomachs, liver or uterus in cows and heifers. What is most important here is there are many causes of peritonitis and if your veterinarian can diagnose it and determine the cause it may in some cases prevent future infections. Some cases aren’t really preventable but at least you can be comforted in the thought there was nothing you could have done.

Common signs of peritonitis are increased temperature, depression and grunting from a painful abdomen. Your veterinarian may take blood for a blood count and fibrinogen levels, which are an indication of inflammatory material collecting in the abdomen. The abdomen is painful on palpation and a veterinary test is the grunt test with a withers pinch.

The disease entity talked about most by producers is hardware disease, which is a form of peritonitis. This is caused by something sharp, mainly metal, penetrating though the reticulum (first stomach) causing leakage of contents and infection. This may even involve infection around the heart.

If more cases are noted treatment can be started earlier and your veterinarian may in certain circumstances advise putting magnets in the cattle. The magnets stay in the reticulum for the life of the animal and any iron metal compound sticks to the magnet to keep it from penetrating the first stomach.

Magnets have come down in price over the years and the good ones are very strong. Intense feeder operations, including dairies, where lots of equipment is used and silage fed has metal getting into the feed and hardware disease can be a recurring problem. If caught early anti-inflammatory drugs and antibiotics, which get into the abdomen, are what your veterinarian may prescribe.

A good many causes of acute diffuse peritonitis result in a fairly sudden death (over one to two days) and that is why autopsies on these cows may give you very usable information.

These deaths can be posted under the BSE testing program in many of the cases as long as they are greater than 30 months of age and meet the other criteria.

A post mortem is absolutely critical to help determine the exact cause of the peritonitis. Sometimes the history may give it away such as a hard calving or head back or a breech birth that was corrected and all these problems may lead to a torn uterus if one is not careful. Then the placenta and uterine contents leak into the abdomen and peritonitis is the result.

In major infections the whole abdomen may be infected and it may actually be very difficult for the attending veterinarian to determine the initiating cause of the infection. Cattle have an amazing ability to wall off the infection minimizing its spread, which is why they can take the most of any species when it comes to abdominal infection.

This is why C-sections can be performed in barns with surprisingly good results as long as some degree of hygiene is performed.

Peritonitis can be caused by such other things as rupturing of abscesses on the liver or the vagina of a heifer from a traumatic breeding by a large aggressive bull.

Grain overload can lead to peritonitis especially around the rumen.

The rectum may rupture at calving or another phenomena called the scissor effect when the cow’s small intestines get trapped between the pelvis and uterus. This happens more with a backward calving. As the calf is expelled the pressure on the intestines creates a cut from the cow’s pelvis. Ingesta spills out internally and the cow usually dies within 24-36 hours. These can happen from a pull or even when a cow calves naturally. Post mortems in these cases identify the cause, and while it generally can’t be prevented the PM rules out other causes of sudden death in cows such as blackleg or grass tetany, which could be prevented.

Two times in my long veterinary career I have had the rectum rip clear through from palpating. This would have caused this same death but in one instance I had the heifer emergency slaughtered and in the other instance I was able to suture the tear back up. This is why in tough calvings or when malpresentations are corrected we check the uterus after to make sure there are no tears. If you discover them have your veterinarian out, as they may be able to suture them up and save the cow.

When treating cows for milk fever and other metabolic disorders certain products are approved for intraperitoneal use but many are not, so be careful. If giving products this way, make sure the needle is new and is given into a clean area. There once was a rumen injector for administering a deworming product directly into the rumen and it was very soon pulled from the market because of the peritonitis it was causing. This could be an infectious process or a chemical peritonitis from the sensitive internal organs having a reaction to the product. Regardless, in either case you have a very sick animal. We must be careful and at first do no harm, so think twice about injecting anything into the abdomen unless advised by your veterinarian.

The newest trend in pregnancy testing is using an ultrasound with an introducer. Your veterinarian must use lots of lubricant on this tool and introduce it carefully if the cows have dry manure. I have heard of two instances where the colon has been perforated by an introducer resulting in a dead cow. Unlike when I did it manually the veterinarian had no idea this had happened. After handling, processing or preg checking it is good to get any sudden deaths posted so any injury or perforations during processing can be recorded and steps hopefully taken to prevent it from happening again in the future.

Peritonitis in young calves can result from perforated abomasal ulcers, blocked intestines, navel infections gone internal, so always keep these conditions in mind when dealing with sick calves. Many methods are used to prevent navel infections and surgery may be done on the other two problems if they are caught early enough.

Work with your veterinarian by posting unexplained deaths as the incidence of many of these causes can be reduced and you may even find a disease you never expected.

A diagnosis of peritonitis on post mortem would be very hard for trained veterinarians to miss but the key is what really caused it in the first place.

Source: Canadian Cattleman

James Stephenson likened the scenes in his shed to that of a ‘horror film’, with cows quickly being paralysed, as the disease, which attacks the nervous system, took hold.

Mr Stephenson, from Clitheroe, Lancashire, first saw signs of the disease on a routine lunchtime check of the herd, predominantly Holstein-Friesians, and found one cow dead in the passageway.

He said: “Another cow was floppy and weak. I rang the vet who came to do a post-mortem and in that time another two had fallen.

“In just a few minutes, the floppy cow had died. It continued like that and, by Monday, 38 were dead.

“I do not think anything can prepare you for it – it was absolutely horrific.

“Our cows are like pets to us and to see them in such a state is heartbreaking.”

Some cows were injected with an anti-inflammatory and penicillin, but Mr Stephenson said it seemed to accelerate the disease.

He added: “We tried to care for the cows by feeding them charcoal and even burnt toast to try to attempt to absorb the toxin, but with no success.”

Other cows which showed advanced signs were euthanised, with only one cow in the affected high yielding herd, a Montbeliarde cross, remaining unscathed.

Dry cows and the low yielders, which were housed about 15ft away at the other side of the shed were not affected.

Tests on feed have all come back negative, but Mr Stephenson said it was likely silage fed to cows had been contaminated with dead game or poultry birds, which are prolific carriers of the bacterium clostridium botulinum, which causes botulism.

In total, Mr Stephenson, who farms in partnership with his father Jim, lost 47 high yielding milkers and three bulling heifers out of the 80-strong herd. He is now working with his vet to source a vaccine for his remaining cattle.

Mr Stephenson said: “Speaking to a lot of our friends and colleagues, this is extremely rare, but it could happen to anyone and awareness is vital. My advice would be to vaccinate. I will be vaccinating all my cattle from now on.”

Source: Farmers Guardian

So when do we need to start preparing our calf barn for winter? The thermoneutral zone for calves is 50-68 F, meaning when temperatures in their environment are below the lower critical temperature of 50 F, they need extra energy to stay warm.

This can be a challenge since 50 F at night often has highs of 70 F during the day.

Usually, calves deep bedded with straw manage this variation by nesting with their legs covered at least to the middle of the back leg when lying down. The next step is adding calf jackets to help keep calves warm.

Studies show that calf jackets improve gain by 0.22 pounds per day compared to those without jackets. Adding jackets when it is warm out may cause the calves to sweat under the jacket and get chills at night.

Regulating temperature

If you have a calf born prematurely, putting the jacket on at night and off during the day is extra work but may help calves who cannot regulate temperature very well. Calf jacket material should be breathable with a water-resistant shell.

It is recommended that producers start using jackets once pen temperature averages less than 50 F for newborn calves up to three weeks old. Once calves are over 3 weeks of age, they are comfortable until average pen temperatures are below 40 F.

The lower critical temperature continues to decrease as the calf’s rumen develops, creating heat to keep them warm. One important management step with calf jackets is to keep the jackets dry, which means calves should be dry before putting jackets on.

If the calf is still damp, you will need to change jackets after a few hours. In order to put jackets on dry calves, you should have clean towels to dry the calves.

Drying the calf

One thing that works very well when calving barn temperatures fall below freezing, or even 40 F, is to have towels in a cabinet in the calving pen to help the cow dry the calf quickly.

When calves are first born and they start shivering, they are burning precious energy. For each degree drop in temperature below the lower critical temperature, a calf needs a one percent increase in energy to meet maintenance requirements.

There are many different calf-feeding programs. With all programs to continue growth, more milk solids have to be fed without solids concentration exceeding 16 percent. The most common way to increase energy intake is to feed either more per feeding or add a third feeding.

While eight hours apart is ideal for three feedings, the most important part is to make timing consistent. Feed the same amount at each feeding, even if that means adding a lunch feeding between your normal feeding times.

Another beneficial practice is to provide warm water at 63-82 F to calves within 30 minutes of finishing their milk. Water intake improves starter intake by 31 percent.

However, it lowers their rumen temperature requiring energy to warm the water and even more energy to maintain weight and allow for growth.

Fresh air

Close attention needs to be paid to winter ventilation. Keeping barns or hutches warm is not really the goal. Keeping air fresh to minimize disease while not allowing a draft on the calves is the goal.

There are many ways to do this. With hutches, it usually means having either permanent winter wind breaks or temporary wind breaks, like straw bales. Winter winds seem to change and bring cold nasty weather out of every direction, even the south.

In calf barns, pens are a microenvironment affected by ventilation and pen design. Studies have found that solid sides slow disease spread but are only beneficial if the front, back, and top of the pens are open, otherwise, they create a high disease microenvironment.

When disease and ventilation is challenging your calves, a properly designed positive pressure tube providing ventilation at a rate of 15 cubic feet/calf/minute can improve calf health without creating a chill.

Source: Farm & Dairy

He joined several other speakers last week at two sessions on dairy nutrition sponsored by the Professional Dairy Producers of Wisconsin (PDPW.)

In his position at the commercial feed testing laboratory he sees what’s happening on dairy farms and how it’s affecting cows. In 2016 many farmers were experiencing listeria and salmonella in their cows.

He related the story of one Wisconsin dairy farm that switched from their 2015 to their 2016 high moisture shell corn and saw their cows drop precipitously in production, from a normal high of 90-plus pounds per cow per day. It was enough to get the farm’s attention – the cows dropped 100,000 pounds of milk production in a month. When they looked for a reason, they found that the corn was high in wild yeast and mold. The problem was diagnosed by testing the total mixed ration (TMR.)

They tackled the problem by adding commercial yeast products and mold inhibitors to the feed, which added a cost of 10 cents per cow per day and the cows came back to about 86 pounds per cow per day, he said.

Though the industry outlook for milk prices isn’t good into the coming year, Goeser told the farmers and nutritionists in attendance at the Arlington Agricultural Research Farm that feeding the cows carefully and monitoring things like mold, yeast and aflatoxins in their feed can show results on the bottom line. It can mean the difference between finding or losing several pounds of milk production per cow and a positive versus a negative margin.

Feed gets “dirty” he noted, at harvest, and during fermentation and at feed out. He showed data from his lab on the amount of “ash” or dirt that is in feed. In 2010, samples averaged 8-8 ½ percent and today it is 10-11 percent and the trend has been up every year. That’s important because pathogens like yeast, mold, mycotoxins and bacteria live in the soil. The more soil in the feed means there are more of those hitchhikers along to wreak havoc on the feed – and eventually the cow.

Bearing that out, he showed a chart of samples tested for fungal loads at his lab; both yeast and mold in feeds and TMR samples are on an upward trend since 2014. He speculated that reduction in tillage may play a role in this trend.

Goeser said that yeast fed in commercial products are designed to be good for cows but wild yeast generally have a negative effect on rumen metabolism and should be prevented from taking over the feeds. He notes that we have a lot to learn about fermentation but we do know that we need to get the air out and drop the pH to get the feeds acidified as soon as possible. Molds and fungi are born in the field and in silage if there is aerobic instability.

Some bad actors in the feed – aflatoxins, mycotoxins — are produced when plants are stressed. “Once present they will be there,” he said. “Fermentation won’t knock them back.” Research is suggesting that these various toxins affect different organ systems in the cow. Some suppress the immune system or reproduction. Some target the liver and kidney. “Very rarely do we have only one toxin present.”

The levels of these toxins found in feed depend on the growing season. Goeser showed a chart with large numbers of samples, dating from 2011-2016 and last year’s corn was double the (1 ppm) threshold in large numbers of samples. The chart is black with data points above the threshold for 2016.

Toxins down this year

“October was dry and warm and 16-percent-moisture corn just isn’t going to ferment,” he said. Corn that gets harvested at 24-25 percent moisture may still ferment but if it’s less than 23 percent, he said it won’t “soften up” and he advised grinding it up as small as possible.

He encouraged farmers to keep an eye on bacterial contamination in their feed as well, which comes mostly from manure. “Don’t put manure on your growing crops. After the alfalfa comes off you may have a day or two to put manure on it but if that alfalfa starts to grow back and then you apply manure, you’re inoculating all those plants.”

Challenges for dairy managers also come when feeding the stored forages and corn. When silage is re-exposed to air, yeast will reproduce by feeding on sugars and carbohydrates and then start to eat lactic acid. When that happens the pH goes up and when it reaches a certain level, bacteria start to grow.

Perfect storm

Dairy cows can ward off certain bacterial challenges if they are not stressed by other factors, he said, like overcrowding or poor cattle handling methods, but if they are also enduring environmental stress they can experience a “perfect storm.”

Goeser further noted that some research is showing that bacteria can “sense” the stress hormones given off by a cow when she’s got problems and this allows them to take advantage of her.

He gets questions all the time about what additives are best to add to dairy rations. Some are useful for binding toxics, boosting the immune system of out-competing pathogens. His advice is to always “test before throwing 10-15 cents per cow per day into a ration. It takes a comprehensive approach.”

The most critical time is harvest and the decision-maker should be on the packing tractor, at the silo or on the bagger, he said, so they can make key decisions about the crop. If it’s too wet there will be ineffective fermentation; if it’s too dry there will be too much air in the feed. “You need to watch the crop coming in and make key decisions,” he advised. Another piece of advice at harvest is to use a research-proven inoculant.

Not your Daddy’s fiber

Dr. David Combs, a professor of dairy science at the UW-Madison, talked with the group about new technologies and innovations in forages that have improved feeding programs for livestock. On the plant side, brown mid-rib (BMR) was a natural mutation in corn that led to improved digestibility of fiber. Alfalfas have been developed with reduced lignin – some by natural breeding and some with genetic modification – and those have led to improved NDF (neutral detergent fiber) digestibility.

Even grasses have been improved for use in high-producing dairy cows, he said, and some of them have higher digestible fiber than alfalfa or corn silage.

The improved fiber digestibility of BMR corn, Combs said, has been shown to increase milk production by 2-3 pounds per cow per day. The reason some of these newer forages can do that is that “every mouthful the cow takes is effectively utilized or she can eat more,” he said.

However, while crops have been improved genetically, that only accounts for about a third of the fiber digestibility in the eventual feed. Two thirds is due to environmental conditions like moisture, growing temperatures and sun intensity. “California dairy producers like the high elevation alfalfa crops because of the growing conditions there,” he noted.

There have also been advances in laboratory testing and analysis of feeds including one that tests for indigestible fiber – uNDF-240 – and one that simulates the cow’s digestive tract to predict total digestibility. That test is called the total tract NDF digestibility or TTNDFD.

Values vary widely

The reason such tests are important Combs said is that fiber digestibility varies widely in forages. “There’s a huge difference and a lot of energy can be left on the table,” he said. Alfalfa hay and silage can vary from 25-70 percent of NDF; corn silage varies from 25-80 percent and grass hay and silage varies from 15-80 percent. “Two units increase in dietary TTNDFD can potentially increase milk yield by a pound.”

Combs noted, and some farmers in attendance confirmed, that garden chippers are being used in the field just before harvest to determine the fiber digestibility of the crop so the farmer can use that information to determine how to use that feed and which group of animals to feed it to.

In corn silage, 25-30 percent of the energy comes from the fiber portion of the feed. In addition, milk fat will increase in cows as fiber digestibility is improved. As margins continue to be tight on the dairy farm, Combs added that corn grain can be pulled out of the ration “if you have more digestible forages.”

Source: Wisconsin State Farmer

Milk fatty acid levels, captured by mid-infrared milk analysis tools, were explained by milk quality specialist Dr. Dave Barbano, Cornell University, during the November Hoard’s Dairyman webinar.

Dairy farmers need analytical results that help them manage feed efficiency, animal health and welfare, and environmental impact in order to improve economic performance and sustainability, Barbano said.

“Ultimately, the success of farm management depends on correct decisions down to the animal-by-animal basis,” he pointed out. “The challenge, particularly in large farm management, is to find the cow of interest that needs something special right now, make a decision and take action.”

Milk production is the sum of the performance of all the individual cows, but generating reams of data can be more overwhelming than helpful.

“We really need to condense it down to the information that helps us make decisions, and not be buried in the sea of numbers,” Barbano said.

Analysis and interpretation

The new testing and data, both at the herd and individual cow level, focuses on milk fatty acid composition and the relation to seasonality of fat and protein.

“These new metrics kind of give us a new window into understanding what’s going on in the interaction between cows, health, feeding, management and so on, that I don’t think we see just looking at the fat and protein content,” Barbano said.

When testing first began five years ago at the St. Albens Co-op, the first thing that came to light was a fairly strong correlation of de novo fatty acids with bulk tank fat tests

Field studies of farms with low de novo (LDN) and high de novo (HDN) fatty acids gathered feed samples, management information and, most importantly, production per cow.

The researchers were surprised to find the high de novo herds of Holsteins/Jerseys actually produced more milk per cow. They also had higher fat and higher true protein.

“In the Northeast in 2014 when we did the study, given the fat and protein price, the difference between the HDN and LDN herds at 25 kg milk/100 cows/year would result in a gross income difference of $8,544 for fat and $15,695 for protein,” Barbano shared.

The study was repeated in 2015 on Holstein-only herds. While there was no difference in production, the HDN herds, again, measured higher levels of fat and protein. At the time, prices for protein had dropped, but the differences between the HDN and LDN herds at 30 kg of milk resulted in a gross income difference of $9,125 for fat and $6,935 for protein for 100 cows/year.

“So understanding how to influence these components and get them up without losing milk volume really is something in terms of trying to push better profitability on farms,” Barbano said.

Impacting de novo

The data showed less feed bunk space per cow (

“This showed up very clearly in both years, in both studies,” Barbano noted.

Higher stall stocking density in pens (>1.1 cows per stall) was also related to lower de novo fatty acids and lower fat and protein test.

The form of the ration and fiber is also important, with higher peNDF as a % of DM for the high de novo fatty acid farms (26.8 vs 21.4%).

High levels of de novo fatty acids in the milk indicates that the rumen fermentation is working very well and high levels of acetate, propionate and butyrate are being produced in the rumen, Barbano explained.

Excellent fermentation of forage produces a larger microbial biomass in the rumen and provides more essential amino acids in support of milk protein synthesis.

“De novo fatty acid measurement in milk is an excellent tool to evaluate the effectiveness of rumen fermentation and forage digestion,” he pointed out.

The relationship between variation in milk fatty acid composition and bulk tank milk fat and protein content for Holstein herds has been upheld by data collected from 167 Holstein farms across the nation.

Instruments capable of testing bulk tank milk for de novo are in use at several cooperatives, including St. Albans and AgriMark, who are providing their farmers with daily results.

Looking ahead

Researchers and farmers are getting a much better understanding of how to use milk fatty acid data for whole herd or milking group diagnostics, Barbano said.

The next step is to develop hardware and software to integrate this milk testing approach into the milking system so farmers can get data on a continuous basis from every cow.

Barbano envisions a inline sensor that will shoot off a “fingerprint” of the milk from each cow, and farmers would get back a list of cow numbers or groups and what needs to be done.

Barbano’s presentation, hosted by Steve Larson, Hoard’s Dairyman, and Mike Hutjens, University of Illinois, was sponsored by Quality Liquid Feeds (QLF). It has been archived online by “Hoard’s Dairyman” and is available for free viewing at hoards.com.

Source: Wisconsin State Farmer

Fifth generation dairy farmers Wayne and Paul Clarke, Dobies Bight improved their operation two years ago with the installation of four robotic milkers run off solar power.

Their daily routine changed overnight. It didn’t take their 350 three-way cross cows long to figure out the new way of doing things and it seems they won’t go back to their old regimented life.

“They’re calmer now when I walk through them,” says Paul. “But if I try to push them into a robot or fetch them from a paddock early, no way.”

The most remarkable discovery – as a result of data collection every time a cow goes to the bails – has been that their worst cow is all of a sudden the best.

“She’s a four-way cross, actually,” Paul explains: Jersey over Illawarra/Friesian and back to Illawarra.

“We were just about ready to sell her and now we realise she’s our most profitable cow producing 9000 litres per lactation.

“Under the robot regime she is just more relaxed, feeding when she wants and how much she wants.

“In the past, when we herd recorded, we came up with a snapshot once a month. Now we know exactly how many litres per day for each cow. It is a lot more accurate. Data collected has identified cows capable of producing more milk from pasture with less reliance on grain. With the cross bred cows outperforming the purebred at the moment. The preference being Friesian over Jersey/Red breeds, with Brown Swiss seemingly too docile.”

David Widdicimbe, marketing agent for the Swedish Delaval robot, said old herd hierarchies were relaxed under a robot regime, with once bullied cows able to hang back and go to the bales when they want.

In the bales the robot washes and blow dries each teat several times before applying individual cups, fitted with a weights and measures ‘approved’ scanning tool that measures flow. The technology also presents the farmer with reports, through Windows-based software, on each teat regarding cell-count and salinity, which is an indicator of early mastitis.

“We can’t compare this technology with the old way,” says Paul. “Before we were in the dairy with the cows and we checked them every time they milked. Now we’re not there so we have to rely on the robot.”

When each separate tests had been milked and measured, cows are free to go; but not just anywhere. Pneumatically powered gates open or shut after identifying each animal by their livestock identification ear tag. Early lactating cows travel around the system generally better, with shorter milking permission times [greater access to the dairy] as the lactation progresses ,milking permission is lengthen allowing late lactation cows longer grazing intervals.

The flexibility afforded by the robot allows cows to milk anytime of day or night.

Source: The Land

Markets continue to move sideways with little prospect for forecast price improvement. None of the factors that are well known give much optimism for price improvement

Penn State University’s November Dairy Outlook showed little optimism for 2018 milk prices. Markets continue to move sideways with little prospect for forecast price improvement, according to Rob Goodling, Extension coordinator for the outlook.

If 2018 price forecasts are realized, the majority of Pennsylvania dairy producers will need to have a cost of production below $17.50 per hundredweight to cash flow. That’ll pose a significant challenge to many dairies.

Milk price projections for 2018, based on Class III and Class IV futures for January through August, range from a $15.35 low to a $16.14 high for Class III; $14.11 to $15.40 for Class IV; and $16.63 to $17.41 for Pennsylvania’s mailbox price.

Components only game in town

Shipping more components remains the best way to improve income. Over the last 17 years, Federal Order 1 butterfat tests have increased an average of 0.14%; protein tests have risen 0.11%. That’s according to a recent Northeast Market Administrator’s bulletin.

But those averages don’t reflect the increases achieved on many well-managed farms. During many dairy advisory team meetings, the conversation focuses on the forage quality and management needed to achieve an average of 6 pounds of components produced daily from each cow in the herd.

Blame the cyber economy?

The majority of Pennsylvania dairy farms are concentrated in the south-central and southeast counties. A recent study commissioned by the Center for Dairy Excellence found that the industry continues to grow and concentrate there. That same area has a tremendous transportation network, which has been a benefit in moving milk to market — note the words “has been”.

Over the past 10 years, this transportation network has attracted a large number of warehouses, or logistics centers, to the area. Proponents of logistics centers forecast that there’s no end to the amount of these structures needed.

These logistic centers are located along this transportation grid for the same reason that the extensive food processing industry in located there — half of the U.S. population can be reached within a 12-hour drive.

Some contend the biggest impact of these logistics centers to dairy is the farmland taken out of production to build these centers. But these logistic centers affect the dairy industry in a much less obvious way.

Anecdotal information indicates that average laborers may earn a wage of $14.50 an hour. As a result, dairy farms within a reasonable commute of any of these centers find they’re faced with a minimum wage floor set by local competition for laborers. If dairies aren’t willing to match the wage rates, it becomes increasingly difficult to recruit and retain employees.

Many Pennsylvania dairies already have a cost structure too high to compete successfully with dairies in other parts of our nation, mainly due to feed costs. Higher labor costs won’t be helpful.

Download the full Penn State Extension Dairy Outlook with price projection tables and graphs.

To explore feed costs and estimated income over feed costs at varying production levels by zip code, check out the DairyCents or DairyCents Pro apps.

Source: Penn State University

DRONE researchers have grounded the technology they use to collect data from the air to help solve production problems in dairies.

University of Melbourne agriculture and food researcher Sigfredo Fuentes says infra-red thermal cameras have been used in a stationary capacity in projects looking at stress in milking herds.

“We can install sensors on the cows to detect heat rate and breathing patterns but they are invasive and never stay in position,” he said.

“So we are trying to do the same thing using the drones but stationary — when the cows come to the robotic milker (at our Dookie campus) we can obtain all the biometrics then.”

Dr Fuentes said it was possible to detect body temperature and heart rates from measurements obtained by filming changes to nostrils and eyes with the technology.

“Changes in the luminosity of the eye section of the cow are really imperceptible to the human eye but we have algorithms to analyse those changes related to the rushing in and out of blood to the face,” he said.

“We are concentrating on pupil dilation in the cow and the white part of the eye to analyse stress.

“We can then try to develop models to predict different parameters.

“In milking, for example, we could predict volume of milk, protein content, fat content and any other interesting target.”

Source: The Weekly Times

An alarming statistic, the Bureau of Labor Statistics (BLS) (2012) reported that “Agriculture, forestry, fishing and hunting was one of only two private industries to experience an increase in the rate of injuries and illnesses in 2011 compared to 2010.” The BLS specifically pointed out that the increase was driven in both crop and animal production (primarily dairy cattle and milk production) industries.

There is a high percentage of contact time between animals and human beings in the dairy industry on a daily basis. How do these injuries occur? Many victims of animal injuries result from being stepped on, kicked, fallen on, crushed by cows or mauled by bulls and gored by animals that have not been dehorned.

When training workers about proper livestock handling practices it is important to remind them that dairy animals have panoramic vision, which means that they are able to see all the way around themselves except for a small blind spot at the nose and rear of the animal.

Knowing how to approach an animal from the side while using verbal cues in a non-threatening manner will minimize spooking the animal. The “flight zone” is often referred to as an animal’s “personal space”. In essence entering the flight zone will cause the animal to move away from you. For example a wild animal will have a large flight zone up to as much as 160 feet in diameter whereas most tame dairy cows will have a very minimal flight zone and can often be difficult to move. Understanding and using the “flight zone” in the proper manner can help facilitate the moving of an animal in a desired direction. Learning the flight zone penetration area will take some practice within each species (See Figure 1.).

Cattle are more sensitive to noise than humans, particularly those at higher frequencies. Yelling and hollering causes stress to animals and can make them more difficult to handle. Staying quiet and calm will help minimize these reactions. Additionally, unexpected loud noises such as banging gates, loud exhaust from air cylinders, starting an engine, etc. may startle animals. One way to help condition cattle is to utilize a radio played at moderate volume in the barn at all times to help reduce the reaction to unfamiliar, sudden noises.

One needs to remember that cattle are herd animals and isolation may cause them to be nervous, stressed or agitated. So when working with an animal, having a companion animal near will help keep the one being treated calmer.

Cattle do remember painful or frightening experiences. If an area of the barn brings-up unpleasant memories for cows such as pokes, slipping or rough handling, they may become unwilling to cooperate and react accordingly.

Good livestock handlers should be able to watch for warning signs of an agitated animal. They will show such signs as raised head or bulls may have lowered heads if they are going to charge,pinned ears, raised tails, raised hair on back, bared teeth, excessive bawling, pawing the ground, and snorting.

Appropriate livestock handling behavior include:

- Slow and deliberate actions.

- No loud noises or quick movements.

- Do not prod an animal when it has no place to go.

- Gently touching animals has a more favorable response than shoving or bumping them.

- We need to respect animals, however not fear them.

- Intact male animals, especially dairy bulls should be considered potentially dangerous at all times and proper equipment and facilities should be made available to assure safety of handlers.

- Animals tend to become highly protective of their young especially during parturition.

- Animals will defend their territory which should be kept in mind at all times, given their size, mass, strength, and speed.

- Cows will typically kick forward and out to the side and will also have the tendency to kick toward the side where they have pain from inflammation or injuries. Young stock may kick straight back also. Thus, if a cow has a single quarter with mastitis you may want to approach her from the opposite side of the affected udder when examining her or utilize proper restraint to avoid being hurt.

Personal hygiene is extremely important as humans can contract diseases from livestock (Zoonosis.) Diseases such as leptospirosis, Staphylococcus aureus, rabies, and ringworm are fairly common whereas anthrax and bovine tuberculosis are rare but still exist. Using personal protective equipment such as splash guards, eye wash stations, gloves, and wash stations along with good hygiene by livestock handlers will minimize contagion. Dead animals should be disposed of in a timely and proper manner to minimize spread or potential exposure to disease.

Lastly, using appropriate livestock handling equipment is a must. Equipment such as man gates in pens, working/squeeze chutes, treatment pens, halters, head-gates, anti-kicking devices, hip lifters or cattle lifters should be available and in proper working order. Facility design is also important including gate placement, pen size, spacing between railings or boards and lighting.

Figure 1. Flight Zone, Temple Grandin

Source: iGrow

Calf management starts before the animal is born.

The pregnant dam should be provided with proper nutrition to ensure that the calf is born strong and healthy.

Immediately after calving, ensure that the calf is breathing by wiping off mucus from its nostrils.

Alternatively, you can rub some straws on the calf’s nostrils to stimulate sneezing or hold the calf’s hind limbs and swing it to remove mucus from the nostrils and provide a clear air way.

The calf’s navel is then tied, cut and disinfected with 2 per cent iodine to prevent infection that may lead to navel ill.

Calf feeding is aimed at providing the required nutrients and encouraging rumen development.

During the first 12 hours after birth, it is extremely important that the calf ingests colostrum, which is rich in nutrients and antibodies.

This is because 24 hours after birth, the animal may not be able to absorb the antibodies.

Colostrum feeding may continue for 4-5 days. During this period, the calf’s rumen is not fully developed and milk ingested goes directly from the esophagus into the abomasums through the esophageal groove.

This groove allows only liquid feeds to pass through but not solids, so at this age, the calf should be fed on the dam’s milk or Intromilk milk replacer.

Intromilk replacer can be fed through buckets or nipple bottles which need to be placed at a higher level where the calf has to stretch their necks to drink.

How to feed a calf. Intromilk replacer can be fed through buckets or nipple bottles which need to be placed at a higher level where the calf has to stretch their necks to drink.

The calf may consume up to 2 litres of milk or more per day and should be fed twice daily.

Calves overfed with milk may develop scours, a major cause of early mortalities.

In the event that there’s scouring, the calf should be treated with Limoxin ws, a water soluble powder.

Milk replacer is a quality feed that is meant to meet the growth and development requirements of a young calf.

A good milk replacer is equivalent to successful calf rearing.

This is because high quality milk replacer ensures that the calf’s growth and performance is higher than that of the cow’s natural milk.

FRESH DRINKING WATER THROUGHOUT

Intromilk is economical and is free from diseases that may be transferred from the dam to the calf.

Intromilk helps in faster rumen development, allowing the calf to start digesting grass earlier hence earlier maturity.

A calf should consume Intromilk equivalent to 10 per cent of its body weight. Some 125g of Intromilk calf milk replacer is added per 1 liter of warm water, mixed and fed immediately.

The calf may be weaned at 12 weeks of age. Weaning is the transition from milk to solid feed. At this age the rumen is usually beginning to develop.

Weaning should be done gradually by feeding calves good quality fodder/hay and concentrates.

The concentrates can be in form of calf pellets, which stimulate rumen function through establishment of microbial population and stimulation of growth of rumen papillae.

It’s important for every animal to consume minerals in their diet. Calves should be fed on mineral blocks adlibitum.

Intromin mineral block is rich in vitamins and essential minerals which provide the calf with all it needs for strong bones.

Calves should be allowed fresh drinking water throughout. Do not give water immediately before the calf drinks milk so that they can ingest sufficient amount of milk.

Calves should be dehorned within the first month of birth as it is less painful and stressful for the animal.

Ear tags may be applied immediately after birth for proper identification and recordkeeping.

Extra mammary teats may be removed when the calf is still young as it is less stressful. These are surgically excised and Limoxin aerosol spray applied to prevent infection.

Bull calves not meant for breeding may be castrated at birth or between 3- 6 months of age as they heal faster and it is less stressful.

Vaccination can be done to prevent diseases like blackleg, Anthrax, FMD, Lumpy Skin and CBPP etc.

Source: Daily Nation

Are Your Cows Sorting?

In 2010, researchers from University of Minnesota evaluated ration change over time in 50 Minnesota freestall barns. At each farm, samples were collected from rations fed to high-producing cows. One sample was collected immediately after the TMR was delivered, three additional samples were collected every two to three hours after feed delivery, and the last sample was taken from the accumulated weigh-backs.

Researchers evaluated particle size in the TMR samples using a threesieve Penn State Particle Separator. On average, the researchers found a noticeable change in the percentage of material retained in the top screen from the initial TMR to the weigh-backs showing cows were selecting against long particle size. In addition, fiber content—percent of neutral detergent fiber (NDF)— of the TMR increased throughout the day.

Similar results were obtained in a Canadian survey including 22 freestall herds. On average, the refused ration was higher in the percentage of long particles recovered in the top screen (19.8% versus 33.1%) and physically effective NDF (17% versus 24.5% dry matter) than the average offered ration.

Effects of Sorting on Milk Components

Feed sorting causes fluctuations in rumen fermentation patterns, and can result in reduced ruminal pH and episodes of subclinical ruminal acidosis. A recent study showed the association between sorting behavior and milk production. The researchers evaluated feeding behavior in 28 lactating Holstein cows individually housed in a tiestall barn at the University of Guelph.

Cows sorted against long particles and in favor of short and fine particles. On average, intake of the longest particles was 78%. Milk production of the group was 90.6 lb. per day with 3.81% and 3.30% protein. The authors found negative associations between feed sorting and milk composition. For every 10% increase in sorting against long particles:

- Milk fat content decreased by 0.10 percentage units

- Milk protein content dropped 0.04 percentage units

Because the average sorting against long particles in the group was 22%, milk fat was reduced by 0.22 percentage units or 0.2 lb. per cow per day due to sorting. Similarly, milk protein was reduced by 0.09 percentage units or 0.08 lb. per cow per day. Using values from September FMMO Advanced Component prices (fat $3.03 per pound and protein $1.54 per pound), the economic impact of sorting in this research herd was 72¢ per cow per day or $263 per year.

In conclusion, feed sorting is a common behavior of dairy cows that could produce health issues and economic losses in the herd.

Source: Animal Science with Extension

From a paddock in North Canterbury, dairy farmer Glen Herud is breaking the mould.

He doesn’t own land. He doesn’t have a permanent milking shed or effluent system. Calves stay with their mothers for up to 15 weeks. In almost every respect, the Happy Cow Milk Company flies in the face of New Zealand’s biggest primary industry.

“I suppose we’re different in quite a few ways really,” the 39-year-old said, seemingly unaware of the disruption his model could have.

JOSEPH JOHNSON/STUFF

Glen Herud owns Happy Cow Milk Company. They milk cows in a mobile milking unit in the paddock, and calves stay with their mothers until they are naturally weaned.

Herud milks his 60-cow herd once a day from a mobile milking unit parked in leased land. Rather than make his cows walk from the paddock to the shed, he brings the shed to the paddock.

READ MORE:

* Lyttelton Coffee Company milk supplier speaks out on trim milk debate

* Milk from the farm wins new favour

On some dairy farms, Herud said, herds can walk up to 4 kilometres multiple times a day on the way to and from the milking shed.

JOSEPH JOHNSON/STUFF

Herud started the company in 2014, originally called Nature Matters Milk Company. He now supplies about 30 cafes in Christchurch and Rangiora.

He designed and built the mobile shed himself, the only one of its kind in the country.

“We’re the first to do it, so we had to get it through Ministry for Primary Industries and all the food safety authority people as well.”