How producers are discovering that the human side of technology adoption matters more than the equipment itself

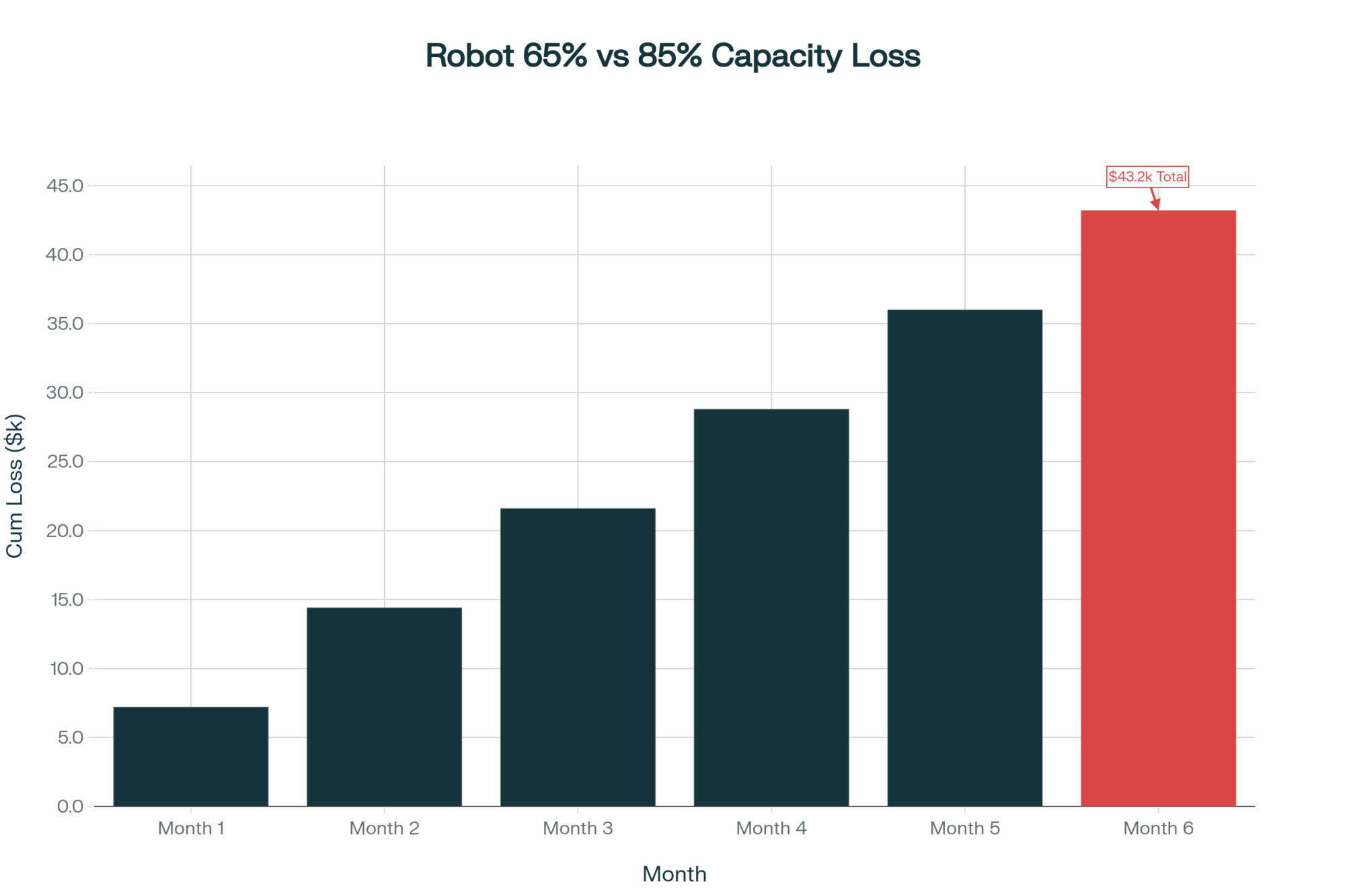

EXECUTIVE SUMMARY: What farmers are discovering about technology adoption challenges everything we thought we knew about implementation success. Producers report that operations investing 100+ hours in comprehensive training achieve roughly 85% utilization rates, while those following standard vendor recommendations of 30-40 hours typically struggle at 65%—a difference worth $43,200 over six months on typical robot installations. Extension specialists from Cornell PRO-DAIRY to Wisconsin’s Center for Dairy Profitability have observed this pattern repeatedly: the disconnect between technology potential and actual performance rarely stems from equipment issues, but rather from inadequate attention to the human side of implementation. European cooperatives that bundle training with equipment purchases and spread implementation over 18-24 months consistently see 10-15% higher utilization rates, suggesting our rush to get operational might be costing us optimization. Here’s what this means for your operation: before signing that next technology contract, consider whether you’ve budgeted as much for training your people as you have for maintaining the equipment—because in today’s tight-margin dairy economy, that preparation gap determines whether you’ll thrive or merely survive with new technology.

You know that sinking feeling when expensive technology isn’t delivering what the salesperson promised? During a conversation at a recent industry meeting, a producer summed it up perfectly: “Six months in, I realized I’d bought a Ferrari but only knew how to drive it like a tractor.”

This builds on what many of us have observed across the industry over the past few years. From conversations I’ve had—whether it’s with tie-stall operations in Vermont or cross-vent facilities in the Southwest—a pattern keeps emerging. The disconnect between technology potential and actual performance? It’s rarely about the equipment itself.

The Training Gap: Different Perspectives, Different Needs

Here’s what’s interesting. At an extension workshop last winter, we got into discussing robotic milking adoption rates. One producer mentioned something that stuck with me—his dealer had recommended the standard 30-40 hours of training. Makes sense, right? However, he then noticed that the most successful robot operations in his area had typically invested what he estimated to be three times that amount in training and education.

Extension specialists I’ve talked with have observed similar patterns, though the exact hours vary considerably. Dealers focus on getting you operational—and honestly, that makes sense from their perspective. They have schedules to maintain and other installations waiting. But there’s a difference between operational and optimized that we’re all learning about the hard way.

To be fair to vendors (and I’ve worked with many good ones over the years), they’re operating within real constraints. Some operations genuinely do fine with standard training. Younger producers often pick up these systems remarkably fast—they’ve been working with technology their whole lives. The challenge is determining which operations require more support before problems arise.

Different Approaches, Different Results

What I find particularly noteworthy is how operations in Europe often structure their technology adoption—at least from what I understand, based on producers who’ve visited. A colleague who spent time touring Dutch dairies mentioned something that really resonated with me. The technology was identical to what he’d installed back home. But their cooperatives commonly bundle training right into equipment purchases, spread implementations over longer timelines, and create structured peer learning groups.

Why does this matter to us? Producers report that these longer implementations achieve roughly 10-15% higher utilization rates than rushed installations—although exact comparisons are difficult to come by. When you’re talking about maximizing a major capital investment, even those modest efficiency improvements add up fast. Whether it’s a rotary parlor automation in California or a robot installation in Wisconsin, that difference matters.

Looking beyond Europe, I’ve heard interesting things from producers who’ve visited operations in New Zealand and Australia. Their seasonal systems create different training dynamics—everyone implements at once, which creates natural peer learning opportunities that we don’t always have here.

Why Experience Sometimes Works Against Us

| Workforce Type | Training Mult | Key Challenges | Success Rate |

| Experienced | 3x | Slow adoption | 85% |

| Young/Tech | 0.7x | Need ownership | 75% |

| Non-English | 2.5x | Language bar | 90% |

| Plain Comm | 2.5x | Tech limits | 95% |

| Family Ops | 1.5x | Role conflicts | 90% |

In my experience, one of the most overlooked aspects is how experienced employees react to new technology. A producer recently shared something that really hit home. His operation employs several folks who’ve been milking cows for decades—exceptional stockmen who can spot a fresh cow developing metritis from across the barn. When automated systems arrived, his best employee nearly walked away. Not because he couldn’t learn the technology, but because suddenly his expertise felt irrelevant.

This gentleman could examine a pen and determine exactly what TMR adjustments to make. Now a computer was telling him what to do. The breakthrough came when they reframed everything: the technology wasn’t replacing his knowledge, it was giving him tools to apply that knowledge to more cows more precisely.

Operations that address these concerns through dedicated learning spaces and realistic timelines generally report smoother transitions—though measuring this stuff precisely is nearly impossible.

Building Networks That Work

Here’s something that works well: producers creating their own support networks. At World Dairy Expo, I heard about a group that formed an informal “technology board”—basically, their nutritionist, veterinarian, successful neighbors using similar systems, and possibly a retired extension specialist. They meet regularly, share what’s working, and troubleshoot problems together.

The investment? Primarily just time, and possibly covering some meeting expenses. However, producers tell me that these networks often save tens of thousands of dollars annually in service calls, not to mention avoiding problems before they occur.

Ontario producers I know use a group chat to troubleshoot issues in real-time. Similar approaches work in Alberta and the Western states. They’ve become each other’s first call when something goes wrong. For producers looking to start something similar, Cornell PRO-DAIRY (prodairy.cals.cornell.edu) offers peer learning resources, and the University of Wisconsin’s Center for Dairy Profitability (cdp.wisc.edu) has frameworks for collaborative networks.

The Real Economics of Training Investment

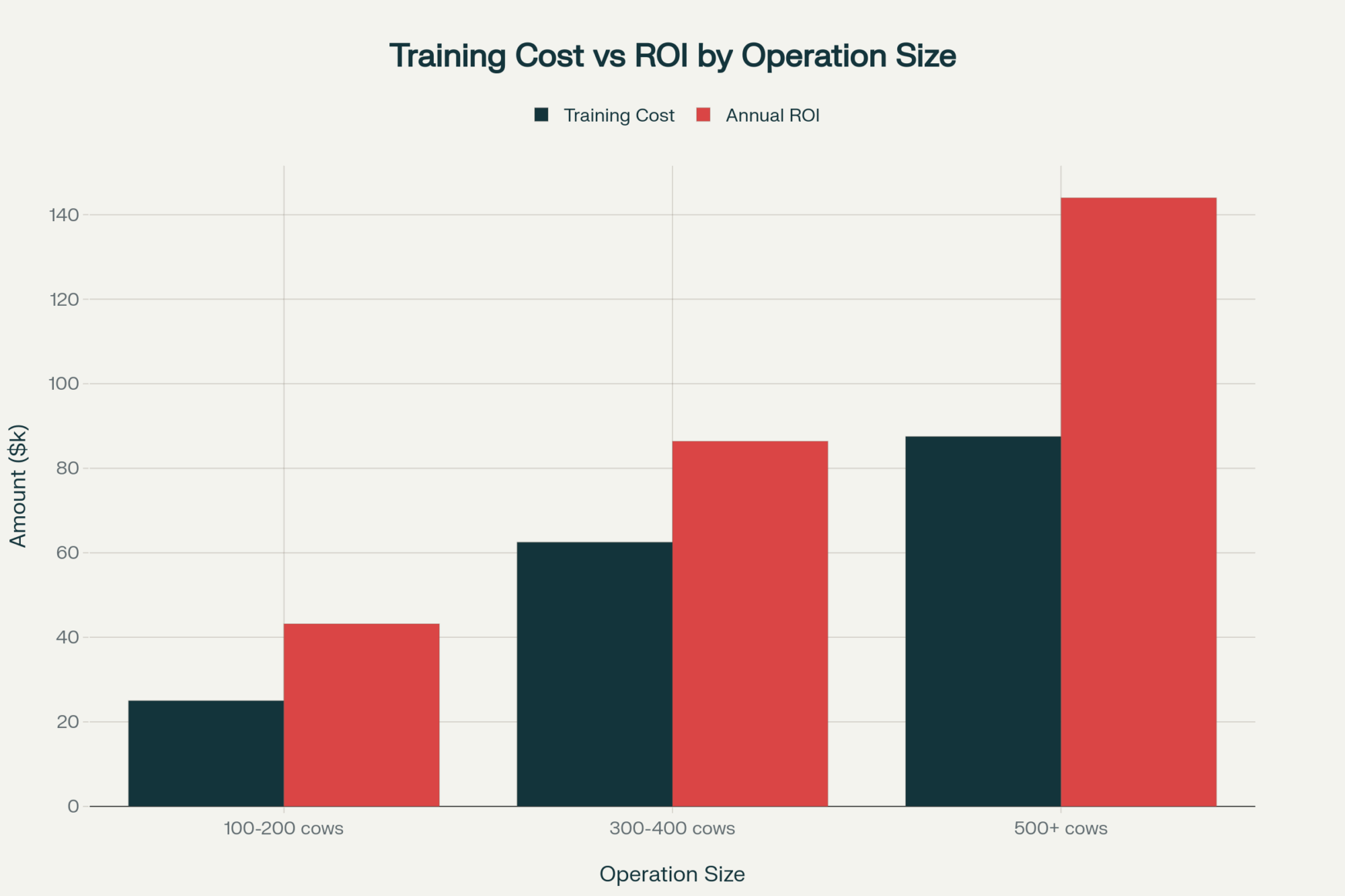

Let’s talk money, because that’s what it comes down to. From conversations I’ve had, the investment in comprehensive training varies enormously. Smaller operations may spend $20,000-$ 30,000 on enhanced training. Larger operations sometimes exceed $100,000, though that includes more than just training.

For a typical 300-400 cow Midwest operation, producers often mention $50,000-75,000 when they really commit to doing it right. Sounds like a lot? Here’s an example calculation one producer showed me:

Six months of robots at 65% capacity instead of 85% = roughly 20% less milk harvested. On a typical 180,000 pounds monthly production, that’s 36,000 pounds lost monthly At recent milk prices around $20/cwt, that’s approximately $7,200 monthly or $43,200 over six months

Suddenly, that training investment appears in a different light. With current milk prices and tight margins, that utilization difference on a $400,000 robot investment makes comprehensive training look like worthwhile protection.

5 Signs Your Operation Needs Comprehensive Training

Based on what successful operations have learned:

- Your workforce is primarily experienced employees over 45—they bring invaluable knowledge, but may need more technology support

- You’re transitioning from tie-stalls or stanchions to automation—a bigger learning curve than parlor upgrades

- Language barriers exist on your farm—whether Spanish-speaking or Plain community workers

- Previous technology implementations have struggled—patterns tend to repeat without intervention

- Your vendor offers only “standard” training packages—one size rarely fits all

Regional and Operational Realities

The approach varies by region and situation. In areas with predominantly Hispanic workforces—whether that’s California’s Central Valley or Idaho’s Magic Valley—language adds complexity. Several producers have had success partnering with community colleges offering technical training in Spanish. Smart use of existing resources.

Operations employing Plain community members face different dynamics. These workers possess exceptional animal husbandry skills—outperforming many activity monitors in heat detection—but may have limited exposure to technology. Pairing experienced workers with younger employees in mentorship arrangements values both traditional knowledge and technical skills.

Family operations spanning from Vermont to British Columbia face unique generational dynamics. The younger generation often drives technology adoption while parents provide operational wisdom for implementation. When this works—and it doesn’t always—it’s incredibly powerful.

Technology Type Matters

Different technologies require different training approaches. Activity monitors? Most operations figure those out with 20-30 hours of focused training. Full robotic systems? That’s often 100+ hours to really optimize. Automated feeding falls somewhere between, depending on complexity.

Converting an existing double-8 parallel to automation means adapting established routines. Installing robots from scratch means creating entirely new workflows. The same applies to rotary parlor conversions versus new installations. One requires unlearning old habits; the other requires building new ones from scratch.

Farms with a history of successful technology adoption tend to adapt more quickly to new systems. It’s not just familiarity with touchscreens—it’s understanding that temporary performance dips are normal, breakthrough moments will come, and patience during learning pays off later. Whether you’re managing Jerseys or Holsteins, focusing on butterfat levels or components, these patterns hold true.

Looking Forward: The Growing Divide

Technology adoption in dairy isn’t slowing down. Recent economic pressures have accelerated it for many operations. The gap between farms that master the human side and those that don’t is widening rapidly.

But we’re collectively getting better at this. Extension programs, such as Cornell PRO-DAIRY, Wisconsin’s Center for Dairy Profitability, Minnesota’s Regional Sustainable Development Partnerships, and Penn State Extension, are evolving their support approaches. Producer networks are strengthening. Even some dealers recognize their long-term success depends on customer success, not quick installations.

What This Means for You

Every farm’s path differs—there’s no universal formula. Grazing operations in Missouri face different challenges than confinement setups in Arizona. Jersey herds have different considerations than Holsteins. What matters is honestly evaluating your specific situation, including your workforce, finances, learning culture, and five-year goals.

Some operations genuinely succeed with standard vendor training—usually those with technical aptitude, previous technology experience, or exceptional vendor relationships. If that’s the case, standard approaches might work well.

But if you’re transitioning from conventional systems, working with experienced but non-technical labor, or implementing complex technology… comprehensive training isn’t an expense. It’s infrastructure, just like your barn or milking parlor.

The timeline pressure from vendors wanting quick installations, bankers wanting immediate returns, and ourselves wanting results—that’s often our biggest enemy. Operations that take a patient-centered approach to implementation generally report better long-term outcomes, although waiting while making loan payments can be tough.

Questions to Consider Before Your Next Investment

Based on what successful operations are learning:

- Have you spoken with three other producers who have successfully used this technology?

- What’s your realistic timeline—can you afford 18-24 months for full optimization?

- Who on your team will champion this change through the tough learning phase?

- Have you budgeted training costs into your financing, not as an afterthought?

- What support network exists beyond the vendor’s initial training?

The Bottom Line

Your next technology investment will likely determine your competitive position for years to come. The question isn’t whether to adopt technology—it’s whether you’ll invest in the human infrastructure that makes it work.

Here’s the challenge: Before signing that next equipment contract, ask yourself—have you budgeted as much for training your people as you have for maintaining the equipment? If not, you’re planning for the 65% utilization scenario, not the 85% one. And in today’s dairy economy, that 20% difference isn’t just numbers on a spreadsheet. It’s the difference between thriving and merely surviving.

The technology won’t wait for us to catch up. But producers who recognize that success depends on people, not just equipment, are building operations that will lead this industry forward. The choice, as always, is yours.

KEY TAKEAWAYS:

- The $43,200 reality check: Operations running at 65% vs 85% capacity lose roughly $7,200 monthly on typical 180,000-pound production—comprehensive training investments of $50,000-75,000 for mid-sized operations deliver clear ROI within the first year

- Build your support network now: Successful producers create informal “technology boards” with their nutritionist, vet, and neighboring farms using similar systems—these peer networks save tens of thousands annually in service calls while accelerating optimization timelines

- Match training to your workforce: Standard vendor packages work for tech-savvy younger teams, but operations with experienced workers over 45, Plain community employees, or Spanish-speaking crews need 3x the training hours to achieve comparable success rates

- Technology type determines approach: Activity monitors need 20-30 training hours, full robotic systems require 100+, and converting existing parlors demands different strategies than new installations—one size never fits all

- Timeline pressure kills profitability: Operations taking 18-24 months for patient implementation consistently outperform those rushing to 60-day operational status—even with loan payments running, the long-term difference between thriving and surviving makes patience profitable

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- AI and Precision Tech: What’s Actually Changing the Game for Dairy Farms in 2025? – This article provides a strategic perspective, revealing the hard numbers on ROI for various technologies like precision feeding and automated health monitoring. It links technology investment to measurable benefits like feed savings and vet bill reductions, helping you prioritize where to spend your capital for the fastest payback.

- The Robotics Revolution: Embracing Technology to Save the Family Dairy Farm – This tactical article offers a case-study approach, showcasing how farms like Hinchley Dairy Farm successfully transitioned to robotics. It details the step-by-step milking process, highlights labor savings, and demonstrates how automation helps solve the labor crisis by shifting your team’s focus to high-value tasks.

- Unlocking Dairy Robot Financing: How Smart Farmers Are Funding Their Automated Future – This piece addresses a critical, financial component of the technology puzzle. It goes beyond the initial cost to explore creative funding solutions like leasing and “pay-per-liter” models, providing actionable strategies to make that multi-hundred-thousand-dollar investment more financially manageable for your operation.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!