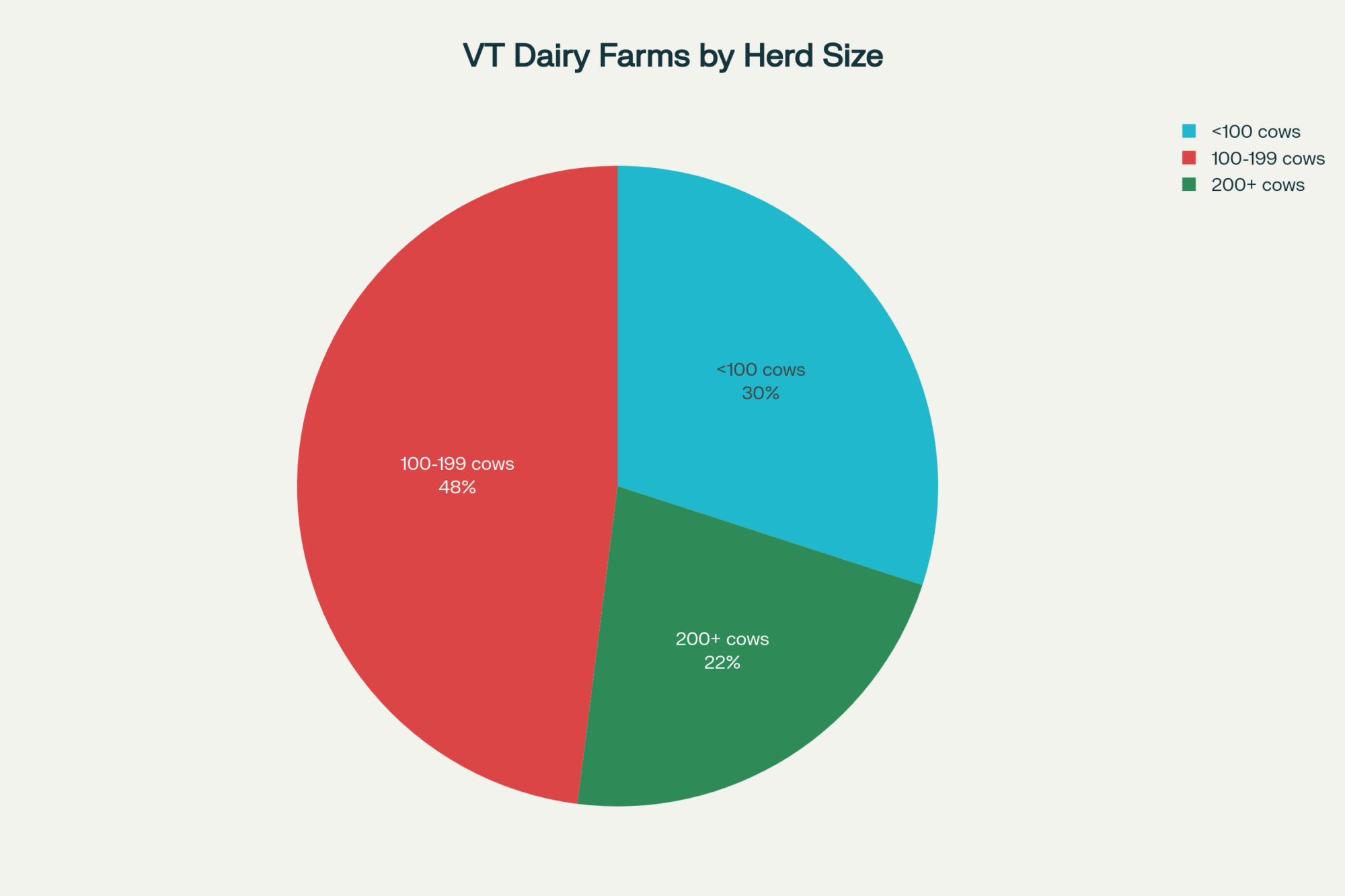

78% of Vermont dairies milk under 200 cows—perfect for robots boosting feed efficiency and milk yield like never before.

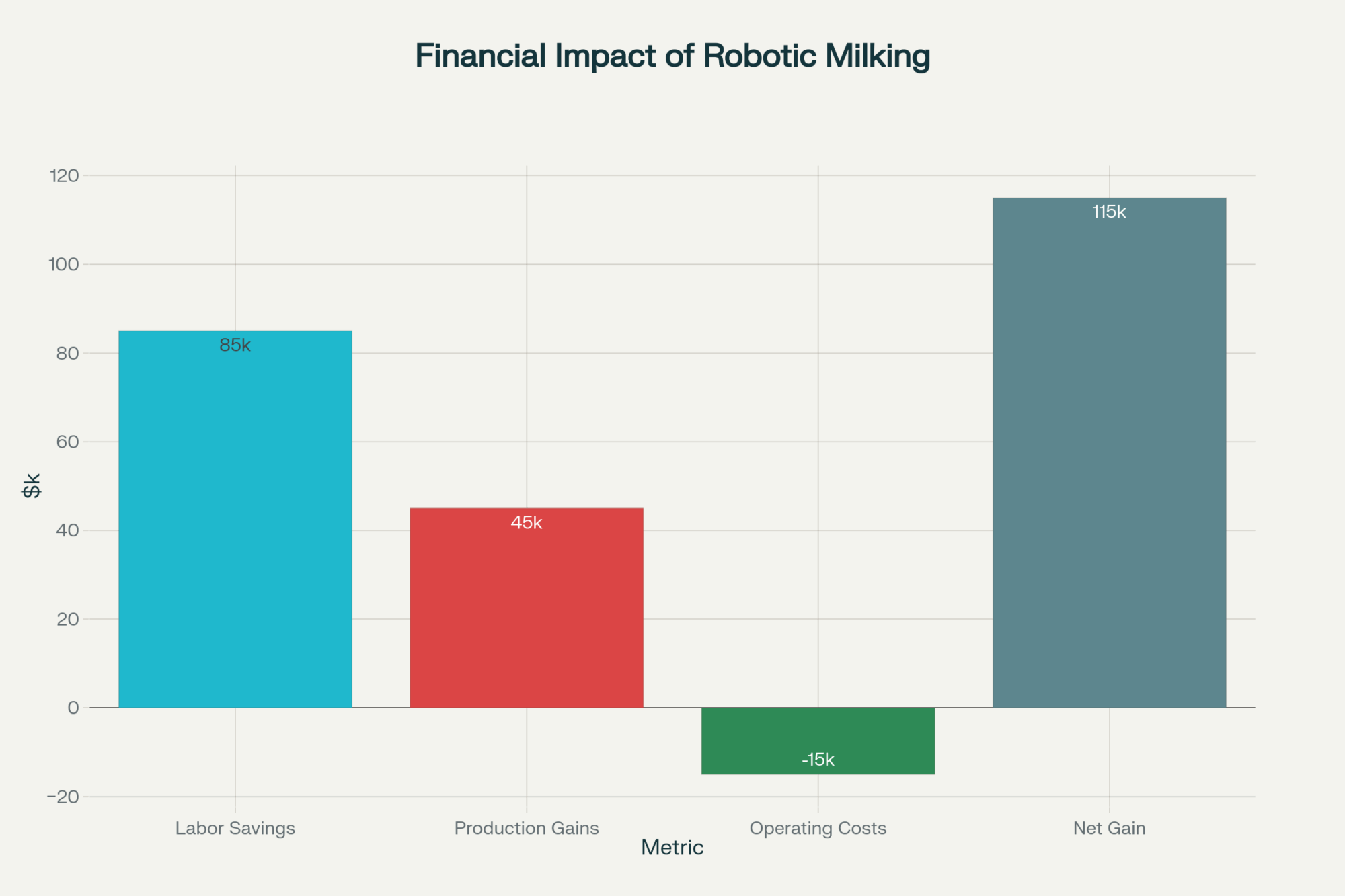

EXECUTIVE SUMMARY: You may be doing things the same way, but robotics, combined with genomic testing, is pushing milk yield and feed efficiency to new heights, driving real profits. Studies show a 60% reduction in milking labor and annual gains of over $115,000 on Vermont dairies. Pair that with feed efficiency improvements from genetics, and you’re looking at a healthier herd and fatter margins. The trend of global farms embracing tech reports stronger ROI amid tight 2025 milk prices and rising feed costs. If you haven’t explored this yet, 2025 is your wake-up call — it’s the ROI and game-changing move your operation needs.

KEY TAKEAWAYS

- Cut milking labor 60% with robotics — get your barn flow diagnosed by UVM Extension for best fit and efficiency

- Boost milk yield and feed efficiency with targeted genomic testing — team up with a trusted genetic advisor now

- Drop somatic cell counts below 200k using robotic health-monitoring tech — catch diseases early to protect profits

- Prepare financially — robotic systems + barn upgrades cost $185k-$230k + $50k-$75k; phase your purchases to suit 2025 market pressures

- If your herd is under 200 cows, you’re sitting on the perfect automation sweet spot — now’s the time to act

Vermont’s dairy industry is at a crossroads. As labor shortages and rising wages squeeze margins, a growing number of producers are discovering that automation isn’t just a luxury—it’s a necessity. This marks a significant milestone for the state’s adoption of robots. With labor costs up and milk margins still tight, the math for robotic systems is finally making sense for many Vermont dairy farmers.

What’s interesting is Vermont’s herd size fits robotic milking systems like a custom glove. A 2024 University of Vermont study shows that about 78% of the state’s dairy farms milk fewer than 200 cows. And since a robotic milker can comfortably handle 55 to 65 cows, most dairies require only 3 or 4 machines.

Milk prices recently averaged $21.50 per hundredweight in July, according to USDA data — a number that’s better than past years but still challenged by inflation and rising feed costs.

The Real Numbers That Matter

So what about the financials? A Penn State Extension study found that robotic milking can reduce milking labor by approximately 60%, with milk quality remaining strong — somatic cell counts typically staying under 200,000. For a 200-cow Vermont farm, that means roughly $85,000 saved on labor, about $45,000 in production gains thanks to healthier cows and more consistent milking, and around $15,000 in operating costs for the machines. That’s a $115,000 annual boost before debt service.

Here’s the catch, though: the payback takes time — usually five to seven years with steady management. And robotic systems don’t come cheap: units run between $185,000 and $230,000 each, with barn retrofits adding another $50,000 to $75,000. Total project costs can exceed $1 million, and with lending rates recently hovering around 7-8%, financing is a significant part of the puzzle.

Vermont Farms Making the Switch

There’s good news on the ground. Ben Williams of Moo Acres in Fairfield spent around $450,000 on two robots. He told folks at UVM Extension how the efficiency gains turned the operation around — “I’m spending less time stressing over milking and more on pasture management and herd health,” he said. The learning curve was real for his team, but the payoff’s starting to show.

Similarly, Four Girls Dairy in Fairfax snagged the 2024 Vermont Dairy Farm of the Year award. Owner Peter Rainville runs 60 cows, averaging 80 pounds daily, by combining robotic milking with solar power and robotic feed pushers to achieve maximum efficiency.

The Vermont Extension estimates that approximately 50 to 70 farms in the state currently use robotic milking, and with labor markets tightening, this number is expected to increase.

The Tech That Keeps Getting Smarter

Now, here’s what’s impressive — the technology behind these robots keeps getting smarter. Health monitoring systems can detect lameness up to 72 hours before it is noticed, using weight and gait sensors. Mastitis detection algorithms identify infections early, which helps maintain butterfat and protein levels — exactly what producers want in their milk checks.

Around here, Lely’s Astronaut A5 is a fan favorite. Its hybrid robotic arm and next-gen teat detection combine precision and speed, while the automatic milk filter saves farmers endless hassle. That little thing alone is a lifesaver on busy days.

But don’t let the tech hype create unrealistic expectations. Vermont’s rural broadband infrastructure remains inconsistent, resulting in delays for remote monitoring and diagnostics. Vermont’s ongoing broadband expansion programs are attempting to close this gap, but they present a significant challenge on farms.

The Financing Hurdle

Financing hits some folks hard and demands serious planning:

- Most banks want 25 to 30% down on robots, noticeably more than the 15 to 20% common with traditional equipment loans

- Manufacturer financing options help, but typically come with vendor strings attached

And here’s a curveball — the cultural shift. Moving from hands-on parlor work to watching data dashboards isn’t easy for multi-generational farm families. It’s a mindset change as much as anything.

Not everyone’s convinced the transition makes sense. Some Vermont producers who looked into robots ultimately decided against them. One Franklin County farmer noted, “The numbers looked good on paper, but between the learning curve and financing requirements, we decided to stick with our double-8 parlor. Maybe in a few years, when the technology matures more.”

| Year | Estimated Robot Farms | % of Suitable Farms | Total Investment |

|---|---|---|---|

| 2020 | 15 | 4% | $3.5M |

| 2022 | 35 | 9% | $8.2M |

| 2024 | 55 | 15% | $12.9M |

| 2026 (projected) | 85 | 23% | $19.9M |

| 2028 (projected) | 120 | 32% | $28.2M |

Bottom Line

So what’s the takeaway? Vermont dairies are staring down squeezed margins and worker shortages. Robots aren’t a silver bullet, but they offer a path forward for many operations. Start smart: get a professional facility assessment from UVM Extension to evaluate barn layouts, cow flow, and infrastructure. Phased installation can keep the process manageable.

Robots don’t just replace labor — they open the door to better data, healthier cows, and more time to focus on running the farm instead of chasing chores.

The question isn’t if automation comes to Vermont dairy, but when. For many operations facing the crunch of rising wages, tight margins, and shrinking labor pools, that moment is now. Those making the move strategically today aren’t just buying equipment — they’re positioning themselves to define Vermont dairy’s competitive future.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- Feeding Strategies for Robotic Milking Success – This article provides tactical, how-to advice on optimizing your feeding strategy to drive robot visits. It reveals practical methods, such as using Partial Mixed Rations and managing bunk space, to increase milk yields and reduce the need for fetching cows, thereby directly impacting daily labor efficiency.

- Stop Blaming Your Robots: The Million-Dollar Management Mistakes Killing Your Dairy’s Profitability – Go beyond the hardware to uncover the strategic management factors that separate successful robotic farms from the rest. This piece offers a critical examination of the long-term trends and economic realities of automation, illustrating how effective management can significantly enhance ROI and improve performance.

- The Robotics Revolution: Embracing Technology to Save the Family Dairy Farm – This article offers a future-focused perspective on how technology is evolving, from AI-driven health monitoring to predictive maintenance. It showcases emerging innovations that will further improve efficiency and sustainability, providing insights into the next wave of opportunities for your operation.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!