NDF digestibility jumped 7.3% when Dutch researchers swapped soybean meal for bug protein. That’s real milk money.

EXECUTIVE SUMMARY: Look, I’ve been watching this black soldier fly thing develop for months now, and the data coming out of Europe is pretty compelling. The biggest shocker? These larvae don’t just replace soybean meal – they actually improve fiber digestibility by over 7 percentage points. We’re talking about going from 46.7% to 54.0% NDF digestibility, which translates directly to better milk production efficiency. The market’s exploding too – from $330 million in 2023 to a projected $4.12 billion by 2032, so costs are gonna drop fast as production scales up. What really gets me excited is the custom nutrition angle… you can literally “program” these bugs by feeding them specific substrates to create targeted amino acid profiles for your herd’s needs. Yeah, regulations are still catching up, but the EU’s already approving insect proteins for other livestock, and North America won’t be far behind. If you’re not at least exploring partnerships with local food processors for substrate supply, you’re missing the boat on what could be the biggest feed revolution since we figured out proper protein balancing.

KEY TAKEAWAYS

- Fiber utilization boost = immediate ROI: That 7.3 percentage point jump in NDF digestibility could improve your feed conversion efficiency significantly – start mapping local food processing facilities within 150 miles to identify potential substrate sources for future BSFL operations

- Feed cost hedge against volatility: With soybean meal running $380-420/ton and BSFL meal prices dropping as the industry scales, progressive operations are already building research partnerships with universities to position for regulatory approval – contact your extension nutritionist about pilot programs

- Custom nutrition potential: Unlike fixed commodity profiles, BSFL can be “programmed” through substrate management to deliver targeted methionine and lysine profiles for fresh cow transitions – calculate your current bypass amino acid costs to see where custom insect protein could replace expensive supplements

- Regulatory momentum building: EU already approved insect proteins for poultry and pigs, with ruminant approval likely within 2-3 years – operations positioning now through research protocols will have first-mover advantages when commercial use gets the green light

- Waste-to-feed integration: If you’re currently paying disposal fees for organic waste while buying expensive protein supplements, you’re missing a potential circular system that could cut costs on both ends – audit your waste streams and protein expenses to identify integration opportunities

Here’s what I’ve been watching unfold across dairy operations from Wisconsin to California… and honestly, it’s got me more excited about feed nutrition than I’ve been in years.

Look, we’ve all heard the sustainability talk. We know feed costs are eating into margins like never before. But what’s happening right now with black soldier fly larvae in dairy nutrition? It’s not just another protein story that’ll fade by next conference season.

I was talking to a nutritionist in the Netherlands last month — you know, where they’re always ahead of the curve on this stuff — and he showed me data that stopped me cold. When they replaced soybean meal with defatted black soldier fly larvae meal in lactating Holstein diets, NDF digestibility jumped from 46.7% to 54.0%. That’s not a statistical blip. That’s a 7.3 percentage point improvement in fiber utilization that translates directly to milk checks.

The thing is, most of us are still thinking about alternative proteins the old way…

What’s Really Happening (That Nobody’s Talking About)

In my opinion, we’re stuck in a mindset where soybean meal delivers what it delivers, period. Corn gluten has its fixed amino acid pattern. Canola comes with whatever Mother Nature decided to give it that growing season. We’ve developed these elaborate nutritional programs to fill the gaps left behind by these commodities, spending fortunes on rumen-protected amino acids to compensate for what we can’t obtain any other way.

But here’s where black soldier fly larvae completely flip this model on its head.

According to recent work from Wageningen University and other European institutions, these larvae not only process substrates but also concentrate and transform nutrients into their tissues, much like a living, programmable feed mill. Feed them omega-3 rich substrates, and you get larvae with fatty acid profiles that make your fish meal look expensive. Provide methionine-rich inputs, and they manufacture high-methionine protein that might make your current bypass program look pretty costly.

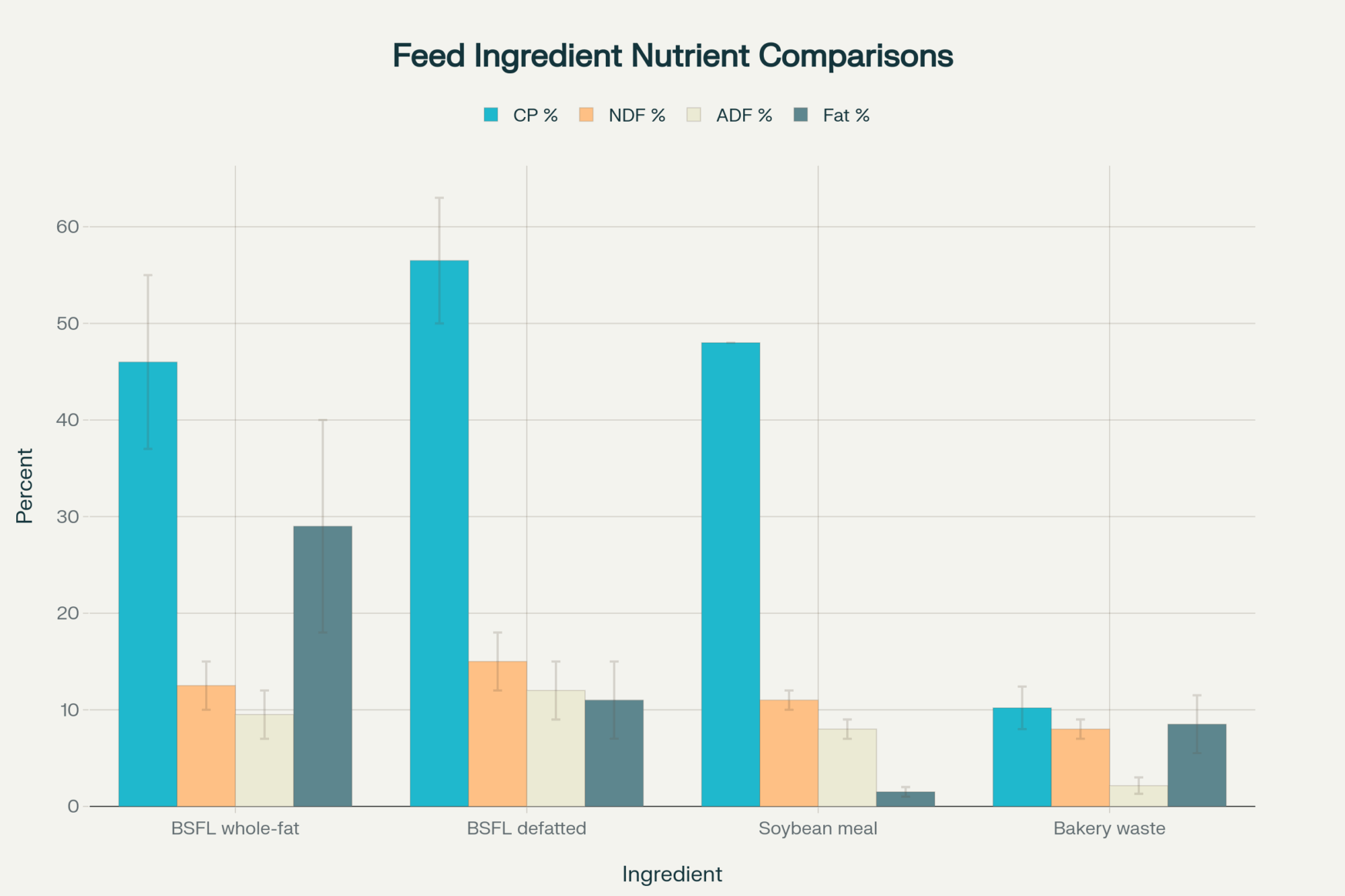

What strikes me about this development is how it challenges everything we think we know about ingredient consistency. BSFL meal protein runs anywhere from 37-63% on a dry matter basis, with amino acid profiles that often exceed soybean meal in key areas. The lauric acid content — we’re talking up to 58.9% of total fatty acids in some cases — brings natural antimicrobial properties that could reduce your feed additive costs entirely.

And that’s just scratching the surface…

The Substrate Story Nobody’s Really Exploring Yet

The substrates these larvae can process read like an inventory of things most of us deal with anyway. Damaged hay that’s too moldy for cattle. Brewery grains past their prime. Vegetable processing waste from local food plants. Even pre-consumer food waste that would otherwise hit landfills.

Instead of viewing these as disposal problems — you know, like dealing with that spoiled silage or off-spec feed — progressive operations are starting to see them as raw materials for custom feed production.

Here’s the thing, though… current BSFL meal costs can be higher than those of conventional protein sources, depending on your location and scale. However, according to market analysis from Polaris Research, the black soldier fly market is expected to jump from $330.19 million in 2023 to $4.12 billion by 2032. That’s explosive growth that typically drives prices down as production scales.

More importantly, you must look beyond the cost of crude protein when considering the functional benefits. Think about it like comparing robotic milking systems to conventional parlors based solely on labor costs — you’re missing the bigger picture.

Quick reality check for your operation:

Is this worth exploring? Ask yourself… Do you currently pay disposal fees for organic waste? Are you located within 150 miles of food processing facilities? Is your soybean meal cost consistently over $400/ton? If you answered ‘yes’ to two or more, please keep reading.

The Research That Changed Everything

What really convinced me that this isn’t just hype was seeing the dairy cow trials coming out of European institutions. The work by Braamhaar and colleagues at Wageningen, published in the Animal Journal this year, replaced soybean meal with defatted BSFL meal in lactating Holstein-Friesian diets.

No significant effects on milk yield or composition when BSFL meal replaced soybean meal. We’re talking about maintaining the production you’d expect from your standard protein source.

However, what caught my attention was the apparent total-tract digestibility of NDF, which increased by 7.3 percentage points. Additionally, research from other groups has shown that cows supplemented with BSFL components exhibit enhanced immune responses, although the specific mechanisms are still being investigated across various research programs.

What’s particularly noteworthy is how a 50:50 mixture of soybean meal and BSFL meal performed as well as pure soybean meal while providing additional benefits. This suggests BSFL meal isn’t just a replacement… it’s potentially an upgrade.

And that challenges some conventional thinking about novel proteins in dairy rations, doesn’t it?

The Regulatory Reality (And Why Timing Matters)

Here’s where things get complex — and frankly, a bit frustrating for those of us watching the technology develop faster than regulations can keep up.

The regulatory landscape varies dramatically depending on where you’re farming. Currently, insect-derived proteins are largely prohibited for ruminants in the EU, the US, and Canada. The ruminant feed ban — which came out of concerns about transmissible spongiform encephalopathies like BSE — prohibits ruminant-to-ruminant protein feeding. Although insects don’t pose the same TSE risks as mammalian proteins, regulatory agencies, including the FDA and the Canadian Food Inspection Agency, remain cautious.

However, and this is crucial, the regulatory momentum is clearly shifting toward approval. The EU has already authorized insect proteins for use in aquaculture, poultry, and pig feed. In North America, the Association of American Feed Control Officials has approved BSFL meal for poultry, with additional species approvals in progress.

The regulatory question isn’t “if” but “when.” Smart operations are positioning themselves to capitalize on approvals as they come through.

What strikes me about the regulatory situation is how it mirrors what we saw with other innovations. Remember the early days of rbST, automated feeding systems, and genomic testing? Smart operations were already preparing for regulatory changes before they occurred.

The key is to start positioning now through research partnerships and pilot programs, all under established research protocols. When regulations change — and they will — these operations won’t be starting from zero.

Precision Nutrition That Actually Makes Sense

Here’s what the most sophisticated operations I’m seeing aren’t considering anymore: simple protein replacement. They’re moving toward precision nutrition strategies that match the complexity of modern dairy rations.

Take, for example, fresh cow management. Early lactation cows have specific amino acid requirements for peak milk production and metabolic recovery. Currently, this means expensive bypass protein and careful balancing of metabolizable protein.

A custom BSFL meal could provide a targeted methionine and lysine profile optimized for this critical period, potentially reducing the need for those pricey rumen-protected amino acids.

Same logic applies to reproductive performance. We know specific fatty acid profiles support reproductive efficiency, particularly for embryo development and hormone synthesis. Strategic substrate management could produce BSFL meal rich in these nutrients, similar to how targeted fat supplementation improves conception rates.

Let’s discuss milk quality differentiation. Premium markets are increasingly demanding specific milk compositions, from A2 protein to enhanced CLA content to antioxidant-rich products. These could all be supported through customized BSFL nutrition.

Cost reality check (because someone’s got to talk numbers):

Current protein costs per ton in most regions are as follows: soybean meal, 48% at around $380-420; canola meal, $320-360; and distillers’ grains, $280-320. BSFL meal pricing varies significantly by region, processing method, and scale; however, the value-added benefits, such as enhanced fiber digestion and antimicrobial effects, could offset the costs of other additives. Additionally, if you’re currently paying disposal fees for organic waste, that creates an extra value.

The economics depend heavily on your operation size, local waste stream availability, and current supplement costs.

What’s Coming Next (And Why It Matters)

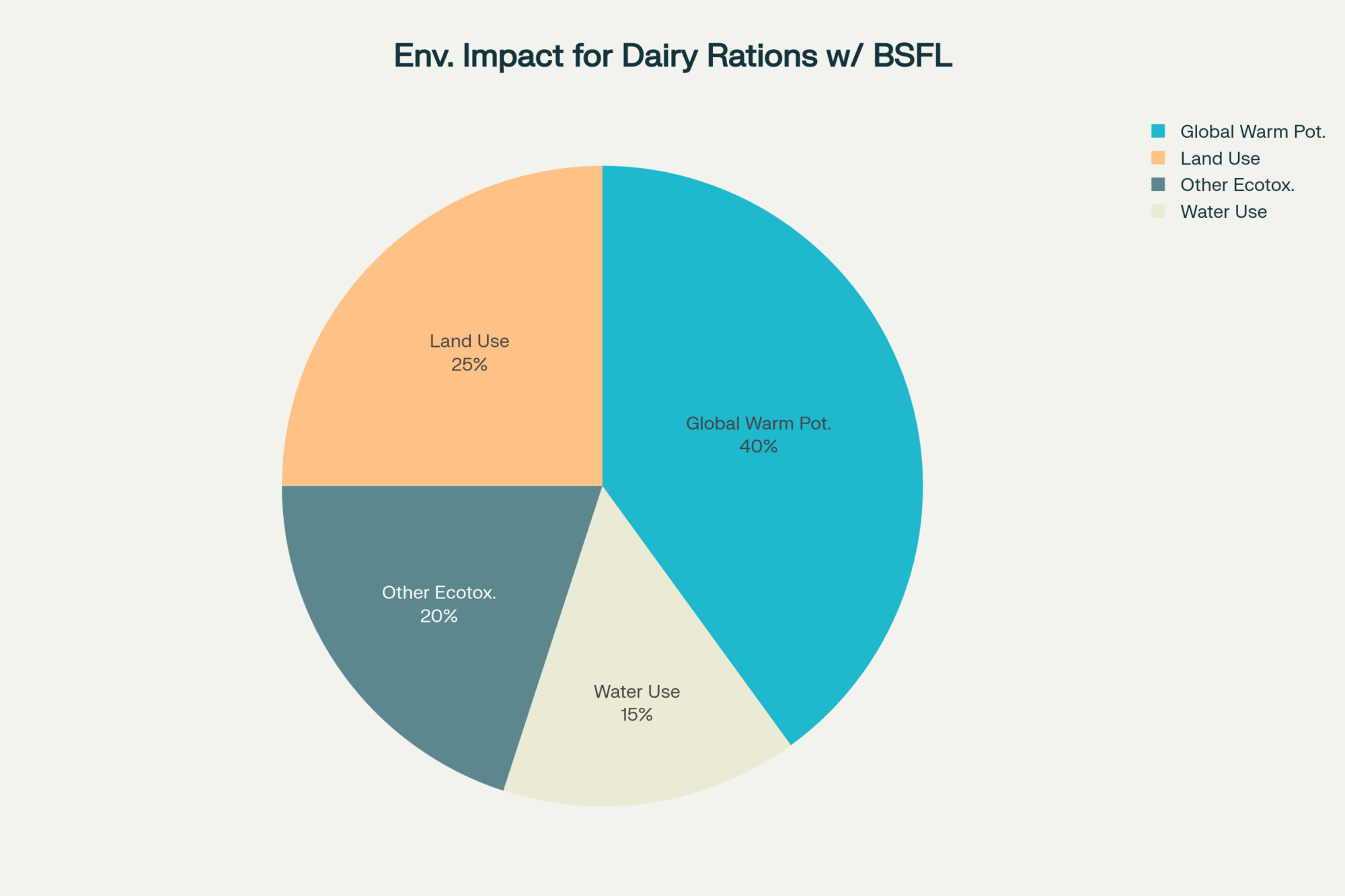

Evidence is accumulating from multiple directions. Economic models show improving viability as production scales. Research consistently demonstrates nutritional equivalency or superiority to conventional proteins. Environmental benefits align with the sustainability pressures we’re all facing.

The global black soldier fly market projections — reaching nearly $4 billion by 2032, according to recent industry analysis — suggest this technology is moving from experimental to mainstream faster than most people realize.

As this technology matures, competitive dynamics are expected to shift rapidly. Operations with integrated waste-to-feed systems will enjoy cost advantages over those purchasing commodity proteins. Custom nutrition capabilities will enable the development of premium products that are impossible with traditional ingredients.

Geographic advantages are already emerging. Regions with abundant food processing waste, supportive regulations, and premium dairy markets are becoming centers for BSFL nutrition innovation. Think about what that means for long-term competitiveness.

The Implementation Reality

What I’m seeing from operations that’re moving beyond just waiting and watching is that they’re taking a phased approach that makes sense.

Phase 1: Assessment and partnerships. Map local food waste streams within 100 miles. Identify potential research partnerships with universities. Calculate current protein costs and waste disposal fees. Connect with emerging BSFL producers in your region.

Phase 2: Pilot testing. Begin with small-scale trials conducted under established research protocols. Focus on partial replacement of protein sources. Monitor cow performance, milk quality, and economic impact. Build relationships with regulatory contacts.

Phase 3: Scale preparation. Develop substrate supply agreements. Plan infrastructure for handling and storage. Create standard operating procedures. Prepare for the regulatory approval timeline.

What strikes me about successful early adopters is they’re not waiting for perfect information or guaranteed outcomes. They’re positioning themselves to capitalize on what’s clearly coming.

You know, the seasonal reality often gets overlooked in these discussions. Substrate availability varies significantly by season and region. Fruit processing waste is abundant during harvest seasons but scarce in winter months. Vegetable processing follows similar patterns.

This creates both opportunities and challenges for consistent BSFL production. Smart operations are already thinking about this — some are exploring partnerships with multiple waste generators to smooth out seasonal variations. Others are examining preserved substrates and ensiling high-moisture materials during peak availability for year-round use.

Regional differences matter too. Operations near major food processing centers — such as the Central Valley, California, southern Wisconsin, and upstate New York — offer different substrate opportunities compared to those in primarily agricultural areas. However, that creates competitive advantages for early movers who solve their local waste stream puzzle first.

Bottom Line

Look, the opportunity to write your own nutritional prescription is emerging. The question for progressive operations is whether they’ll create these new feed strategies or eventually buy them from competitors who have moved first.

The feed revolution isn’t coming — it’s already started. Operations are quietly building competitive advantages that will compound over the next decade. Custom substrate management. Targeted amino acid profiles. Integrated waste valorization. Reduced input costs. Enhanced animal health.

Smart producers are already asking the right questions: How can we turn our waste streams into competitive advantages? What partnerships will give us access to custom nutrition we can’t get anywhere else? How do we prepare for the regulatory changes that are clearly coming?

Those answers will determine who leads the next phase of dairy nutrition… and who follows.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- Stop Burning Money in Your Feeder: 7 Ways to Maximize Feed Efficiency – This article provides immediate, practical strategies for optimizing your current feeding program. It reveals actionable methods to reduce feed waste and improve conversion, directly impacting your bottom line while you explore future innovations like alternative proteins.

- The Surprising Economics of Sustainable Dairying – This piece examines the market forces and consumer demands making sustainability a financial imperative. It provides the strategic framework for understanding how innovations like BSFL fit into a broader business model that turns environmental stewardship into a competitive advantage.

- Turning Trash into Treasure: The Untapped Potential of Upcycled Feeds – Complementing the BSFL discussion, this article explores other emerging methods for converting agricultural byproducts into valuable feed ingredients. It demonstrates how an innovative mindset toward waste valorization can unlock new revenue streams and improve your farm’s circular economy.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!