Nebraska’s dairy disaster reveals how processor compliance failures create new risks for farms—and what smart producers are doing to protect themselves.

EXECUTIVE SUMMARY: Recent investigation of Norfolk’s Actus Nutrition reveals how processor environmental failures create unprecedented business risks for dairy farms, with 284 violations in 12 months forcing municipal officials to work years without vacation to prevent system collapse. What makes this particularly concerning is that Nebraska’s consolidation from 650 farms to just 73 has created dependency relationships where producers defend violating processors rather than demand accountability. Meanwhile, European dairy farmers are turning similar compliance requirements into profit centers, with programs like Arla’s FarmAhead generating up to 2.4 Eurocents per liter for sustainability performance—proving environmental responsibility can enhance rather than threaten farm economics. Research shows that most standard farm insurance policies exclude environmental liability originating from off-farm sources, leaving producers exposed to cleanup costs that average six figures for minor incidents. The trend toward Extended Producer Responsibility in regulatory frameworks suggests farms may face increasing liability for supply chain environmental impacts they can’t control. Smart producers are already implementing five-step protection strategies: comprehensive documentation, processor transparency demands, alternative relationship development, insurance gap assessment, and information-sharing networks. Documentation beats desperation, alternatives beat dependency, and organized farms consistently outperform isolated ones in managing these emerging risks.

You know that uneasy feeling you get when something doesn’t smell right? Here’s a story that should make every dairy producer sit up and take notice.

Picture this: You’re running a clean operation, adhering to every regulation, maintaining excellent butterfat performance, and achieving solid somatic cell counts. Your processor, on the other hand, is breaking environmental laws more often than a rookie employee breaks equipment.

When the cleanup bills start rolling in—and they will—guess who might be holding the bag?

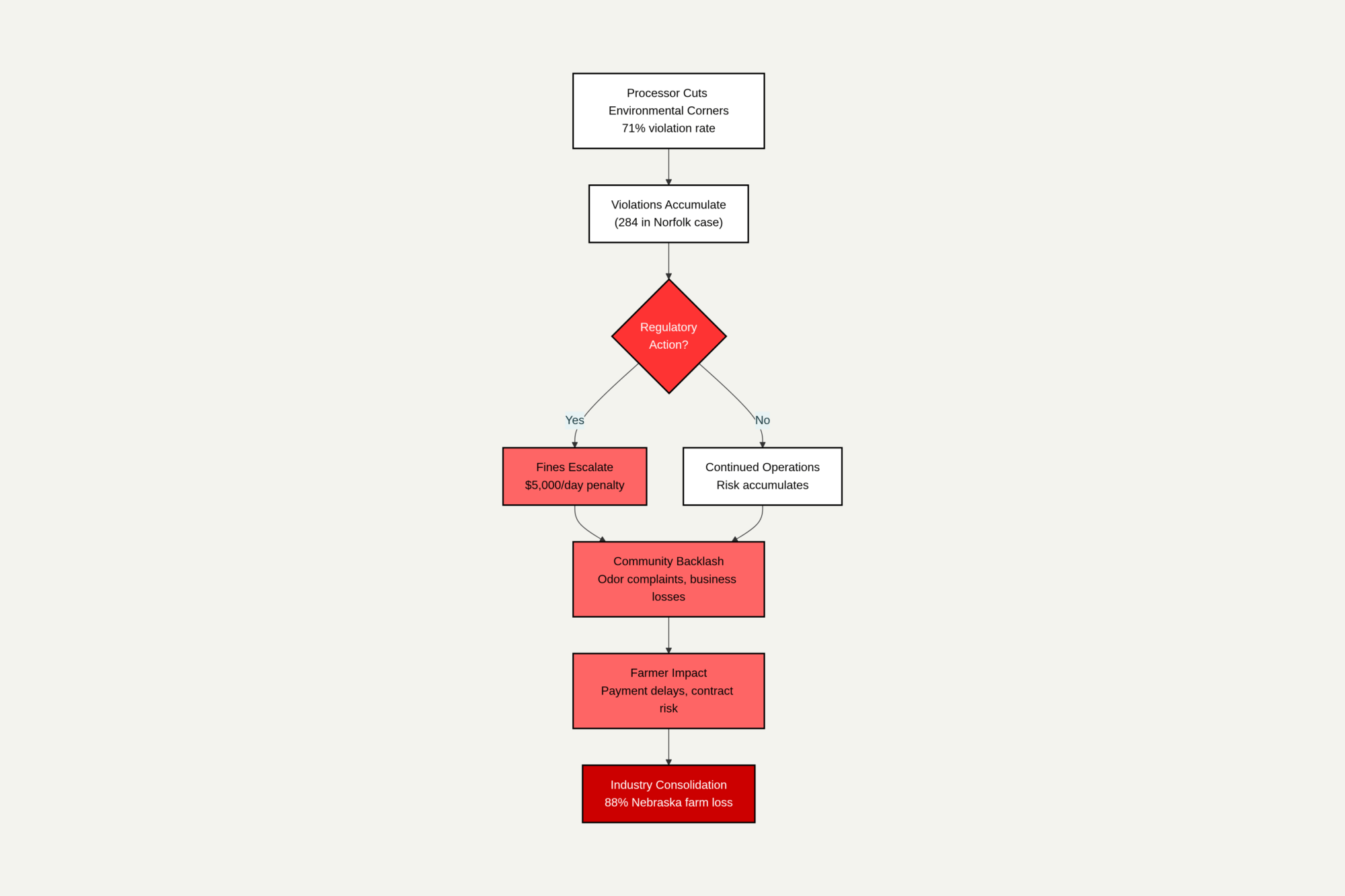

It’s happening right now in Norfolk, Nebraska, and frankly, it should be keeping all of us up at night. Actus Nutrition managed to rack up 284 wastewater violations over just 12 months, according to detailed reporting from Nebraska Public Media and Flatwater Free Press. That’s a 71% failure rate, as documented by Norfolk’s wastewater superintendent Robert Huntley.

Let me put that in perspective: they were violating environmental laws more often than they were following them.

The violations became so severe that Huntley worked two consecutive years without taking a vacation, as he was afraid to leave the treatment system unattended. Two years. Think about that—a municipal employee couldn’t trust a dairy processor not to destroy the city’s wastewater system while he was gone for a week.

And here’s what makes this bigger than one processor’s mess-up: those 284 violations happened while politicians called for “cooperation” and Nebraska’s 73 remaining dairy farms watched their only local market systematically break environmental laws. It’s a window into how industry consolidation has created business risks that many of us have yet to fully grasp.

When Your Lifeline Creates New Liability Risks

Mike Guenther runs a third-generation dairy operation near Beemer, and when he talked to reporters, he said something that really stuck with me: “We would not be dairy farming today if that market did not open.” His family’s operation relies entirely on a processor that fails to meet environmental compliance nearly three-quarters of the time.

But that’s not just Mike’s problem anymore. It’s becoming the new reality in regions where processing has consolidated. Nebraska went from 650 dairy farms in 1999 down to just 73 today, according to the same Nebraska Public Media investigation.

When those numbers shift that dramatically, the whole power relationship changes. Instead of processors competing for your milk, you’re competing for processor access.

This dynamic shifts risk away from the folks creating the problems. All that individual farm management excellence—fresh cow management protocols, transition period nutrition, dry lot systems—becomes less protective when business continuity depends on someone else’s environmental compliance.

You can run the cleanest operation in your county, but if your processor is trucking “high strength waste” to undisclosed locations (which is exactly what EPA inspectors caught Actus doing), you’re suddenly exposed to risks you never created.

Looking at what happened in Norfolk, several types of risk emerge that affect all suppliers equally:

- Payment disruption becomes a real possibility when regulatory actions start affecting the processor cash flow

- Environmental liability exposure creeps in when cleanup costs might exceed what processors can actually pay

- Contract stability gets shaky when processors face regulatory pressure

- Access restrictions emerge as more buyers want to verify environmental compliance throughout their entire supply chain

These risks persist regardless of the quality of farm management. When Actus faces $5,000 daily fines for biochemical oxygen demand violations that literally “killed the microorganisms needed to treat the city’s wastewater,” according to municipal reports, every single farm shipping there faces potential consequences.

Five Essential Steps to Protect Your Operation

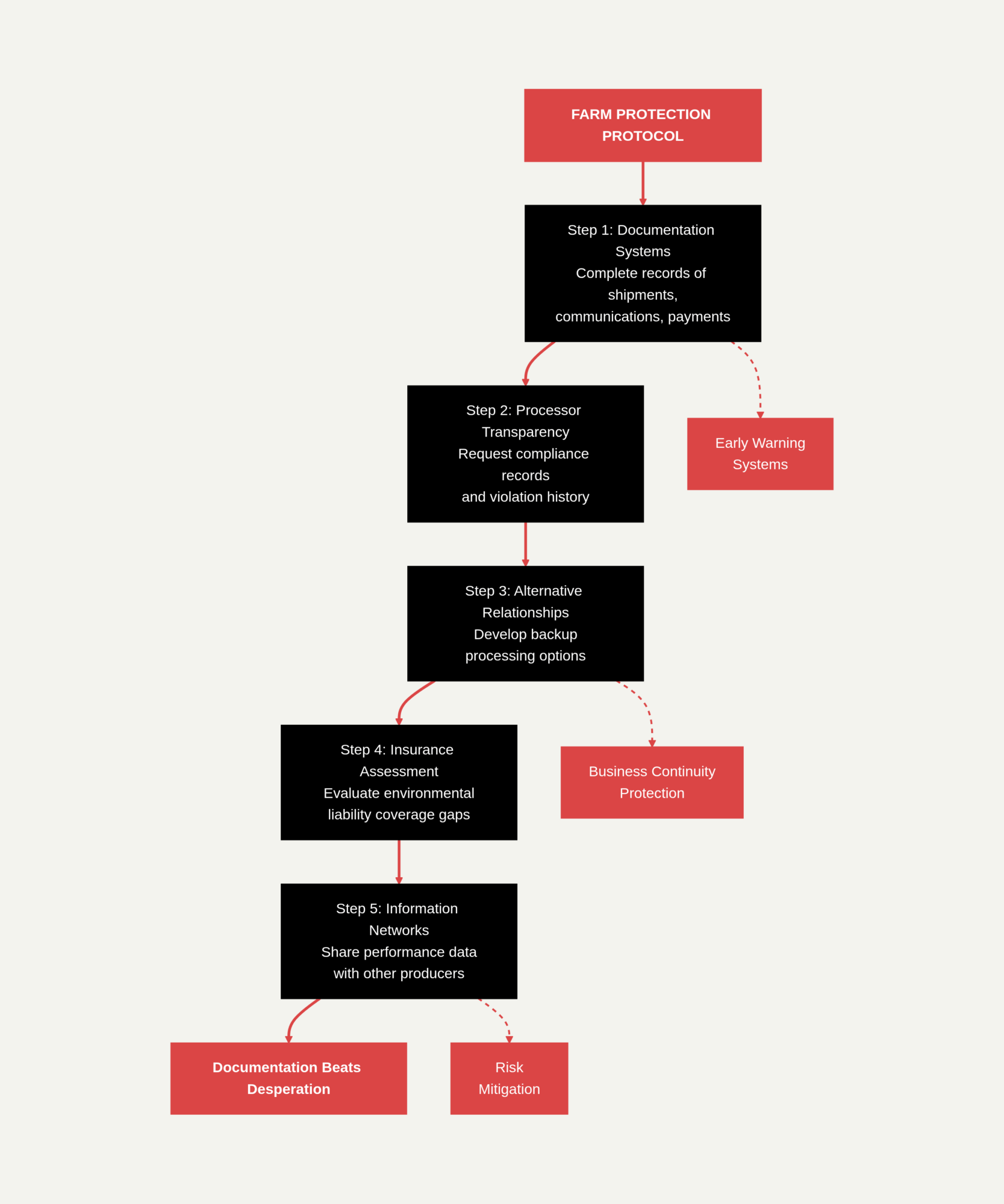

The producers who seem to be handling this well have developed systematic approaches focused on five main areas:

Step 1: Build Rock-Solid Documentation Systems

Create detailed records of every processor relationship and milk shipment. This becomes crucial if environmental liability issues ever arise, because you’ll need proof of exactly what materials you contributed to processor waste streams and when.

Your documentation system should include:

- Complete milk shipment records with dates, volumes, and quality data

- All communications with processors—emails, texts, contract modifications

- Payment records and any unusual delays or adjustments

- Transportation and pickup confirmations

- Details about what your current insurance actually covers and what it doesn’t

Wisconsin producers who maintain monthly spreadsheets tracking payment timing across different processors can spot systematic problems weeks before farms without documentation.

Step 2: Request Complete Processor Transparency

Ask any processor receiving your milk to provide information about their environmental compliance status, current violation records (which are generally public information anyway), waste disposal documentation and permits, and treatment system capacity information.

Frame this as standard business due diligence—because that’s exactly what it is.

Processors willing to provide transparency usually have better compliance records. The ones who push back or delay responses tell you something important, too.

Step 3: Develop Alternative Processing Relationships Systematically

Identify processors accepting new suppliers in your region, research their environmental compliance track records through public records, understand pricing and terms differences, and calculate hauling costs and logistics requirements.

Norfolk shows why depending entirely on single processors creates unnecessary risk. Even when your primary relationship is working well, backup options provide crucial business continuity protection. This doesn’t mean you need to split production, but you should maintain regular communication with secondary processors about capacity and terms.

Many Midwest producers maintain relationships with two to three processors, even if they’re primarily shipping to one. Takes extra effort, but provides options when situations like Norfolk develop.

Step 4: Evaluate Your Insurance Coverage Gaps

Most standard farm policies don’t cover environmental liability that originates from off-farm sources. This creates potential gaps in coverage for situations like gradual contamination from downstream facilities, transportation-related incidents beyond your farm gates, and supply chain environmental issues.

Take a hard look at what your current farm insurance policies actually cover regarding environmental issues, and consider whether additional environmental liability protection might make sense for your specific situation.

Step 5: Join Information-Sharing Networks

Connect with other farms that ship to the same processors or face similar risks. Share information about processor performance, publicly available compliance information, payment patterns, and alternative market options.

Here’s how this works: If you’re shipping to a processor that starts delaying payments by 5-7 days, you might assume it’s a temporary cash flow hiccup. But if five other farms report the same delays, that suggests systematic problems affecting everyone. That shared information helps farms make better decisions about risk management.

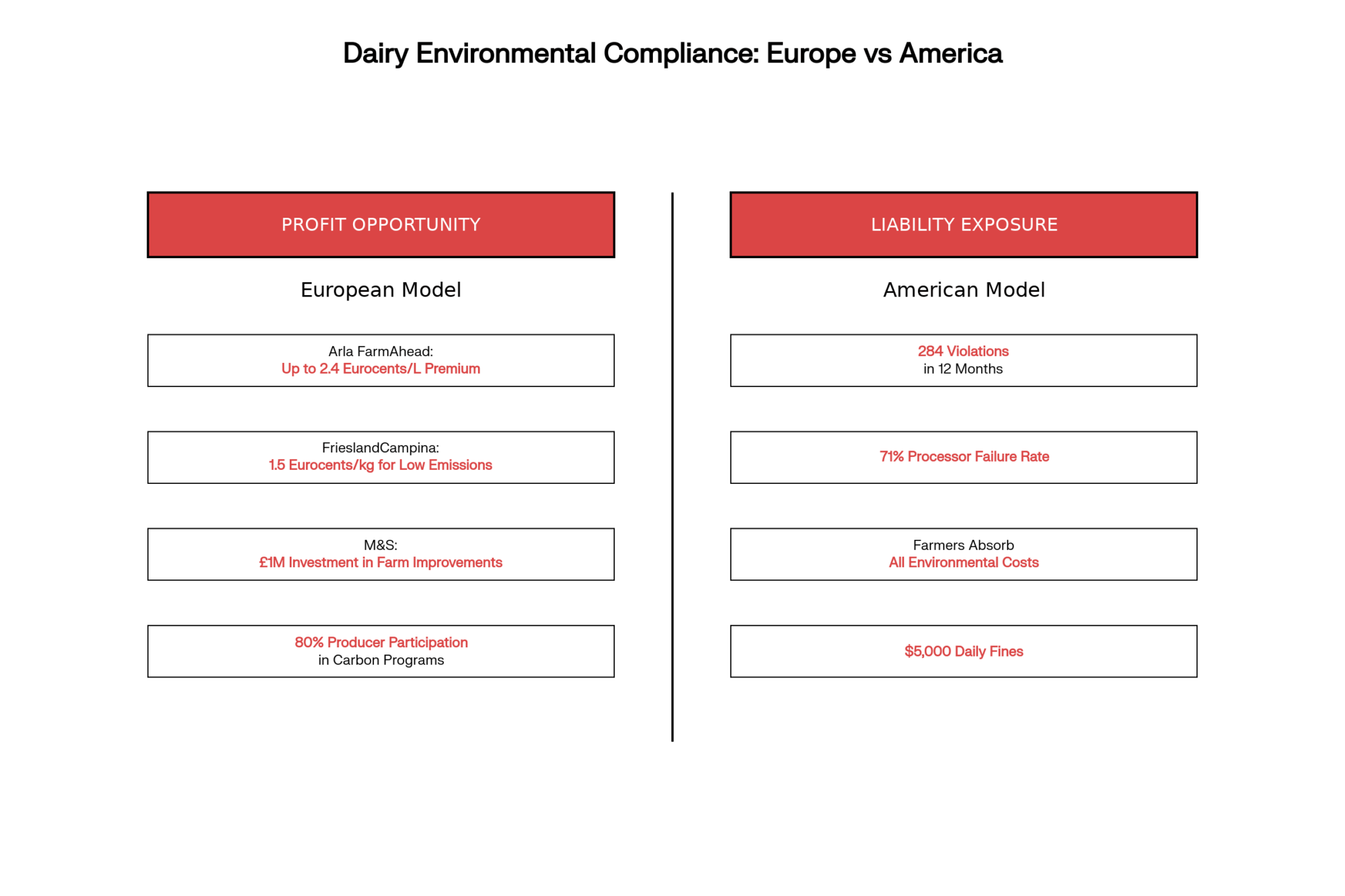

What Europe’s Doing Right with Environmental Compliance

While American producers face environmental liability concerns stemming from processor failures, European producers have leveraged environmental compliance into profitable opportunities. The contrast shows what’s possible when farms organize differently.

UK dairy farmers achieved an 80% participation rate in carbon footprinting programs, facilitated by cost-sharing agreements with retailers, as reported in our previous coverage of these initiatives. Instead of farms absorbing all environmental compliance costs individually, producers worked collectively to get retailers and processors to share sustainability investment costs.

| Region | Company | Emissions Target | Premium | Key Program | Investment |

| European | Arla Foods | 63% by 2030 | 1.5-2.4¢/L | FarmAhead Chk | Retailer part |

| European | FrieslandCamp. | 33% scope 3 | 1.5¢/kg | Nutrient Cycle | $47M Mars |

| US | Actus Nutrit. | None | None | Compliance | 284 violations |

| US | Typical US | Limited | Minimal | Reg minimum | Cost-cutting |

Here’s what that looks like in practice:

- Arla’s FarmAhead program pays farmers up to 2.4 Eurocents per liter for verified sustainability performance, according to documentation from the World Business Council for Sustainable Development

- FrieslandCampina pays 1.5 Eurocents per kg when farm emissions drop below specific thresholds, as reported in industry publications

- M&S recently invested £1 million in methane-reducing feed additives for their milk suppliers, according to Dairy Reporter

The key difference is that organized producers created leverage to ensure environmental improvements generate shared benefits, rather than just imposing costs on farms. When retailers profit from sustainability marketing claims, producers get compensated for generating the performance that supports those claims.

Quick-Start Protection Checklist

This Week:

□ Print and organize all milk receipts from the past 12 months

□ Create a digital backup of all processor communications

□ Request environmental compliance records from the current processor

□ Contact the insurance agent about environmental liability coverage

This Month:

□ Research alternative processors in hauling distance

□ Connect with 3-5 other farms shipping to the same processor

□ Document current payment timing and contract terms

□ Calculate costs for backup processing relationships

Next 30 Days:

□ Establish monthly documentation routine

□ Build information-sharing network with nearby producers

□ Evaluate additional insurance coverage options

□ Create emergency communication plan for processor issues

How Environmental Failures Actually Hit Your Bottom Line

When Actus got caught illegally disposing of dairy waste during EPA inspections, it created immediate concerns for every supplier farm. Payment delays become possible when regulatory fines reduce the processor’s cash flow. Contract modifications or outright cancellations can happen when processors decide they need to reduce waste loads.

Documentation requests from environmental regulators begin to flow as they trace waste sources back to individual farms.

David Domina—an environmental attorney with experience in major agricultural cases, including the Keystone Pipeline litigation—noted that similar Nebraska cases involving processors exceeding wastewater capacity “resulted in consent decrees with substantial fines.” These settlements typically include ongoing compliance monitoring and financial penalties that affect processor operations for years.

Those costs ultimately impact the farms supplying them.

There’s a growing trend in regulatory frameworks toward holding various parties in supply chains responsible for environmental impacts throughout the entire production process. While this is not yet widespread in the dairy industry, the regulatory direction appears to be moving in that direction.

When Collective Action Makes Financial Sense

The most successful producer responses to processor environmental risks involve collective organization that builds information-sharing capabilities while maintaining individual farm autonomy. This addresses shared risks through coordinated action without requiring formal cooperative structures.

Pennsylvania producer groups coordinate information sharing about processor performance without forming legal partnerships. They meet monthly to share their observations on payment timing, communication quality, and operational reliability. This creates earlier warning systems and stronger documentation for addressing problems.

Environmental liability documentation efforts can be shared among multiple farms to reduce individual legal consulting costs. Processor performance monitoring across multiple farms identifies systematic issues that deserve attention. Alternative processing coordination allows producer groups to collectively explore backup options and share information about terms and capacity.

Learning From International Approaches

Canadian dairy policy includes proAction environmental requirements that create shared responsibility for environmental performance across supply chains, according to Dairy Farmers of Canada documentation. Rather than isolating environmental liability on individual farms, the system creates collective standards with shared compliance support.

These frameworks suggest approaches where environmental compliance becomes a shared responsibility of the supply chain, rather than an isolated liability of individual farms. That’s different from situations like Norfolk, where farms may absorb environmental risks for processor compliance failures they can’t control.

International approaches often yield better environmental outcomes overall because they align incentives across the entire supply chain, rather than placing all responsibility on individual farms.

The Bottom Line

Norfolk’s 284 violations prove that the old model—where farms focus entirely on individual excellence while trusting processors to handle their responsibilities—no longer provides adequate protection in today’s complex regulatory and market environment.

Environmental compliance is becoming an increasingly important factor in processor relationships and market access—whether you’re in California’s Central Valley, dealing with water regulations, or in New York, managing nutrient management plans, or in Idaho, navigating air quality requirements. The specific regulations vary by region, but the trend toward supply chain accountability is a universal phenomenon.

The producers who recognize this shift and adapt their risk management approaches will be better positioned for whatever comes next.

The European examples demonstrate that environmental compliance can become a profit opportunity when supply chains effectively share responsibility. Whether American producers will develop similar collaborative approaches remains to be seen, but Norfolk’s disaster is already laying the foundation for change.

The next chapter is being written right now. The question is whether you’ll learn from Norfolk’s disaster in time to protect your operation—and maybe even turn environmental compliance into the competitive advantage it should be.

Because at the end of the day, documentation beats desperation, alternatives beat dependency, and organized farms beat isolated ones every single time.

Start with your documentation this week. Your future operation will thank you.

KEY TAKEAWAYS:

- Document everything systematically – Wisconsin producers tracking payment timing across multiple processors identify systematic problems weeks earlier than undocumented farms, providing crucial early warning for business decisions

- European sustainability premiums reach €96,000 annually for larger operations through programs like Arla’s FarmAhead, proving environmental compliance can generate substantial profit when supply chains share costs rather than dump them on producers

- Standard farm insurance excludes processor-related environmental liability, creating coverage gaps for gradual contamination, supply chain issues, and cleanup costs that typically exceed $100,000 even for minor incidents

- Alternative processing relationships provide crucial protection – Midwest producers maintaining backup relationships with 2-3 processors gain negotiating leverage and business continuity that single-source operations lack during regulatory crises

- Collective information sharing creates 10x better early warning systems than individual monitoring, with Pennsylvania producer groups identifying systematic processor problems months before they affect individual farm operations

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The Ultimate Guide to Contingency Planning for Dairy Farms: Why Paranoia is Your Best Friend – This tactical guide provides a detailed blueprint for building your own farm’s crisis plan. It reveals specific strategies for financial readiness and workforce redundancy, helping producers build the operational resilience needed to protect their business from both on-farm and off-farm disruptions.

- Will Your Dairy Farm Survive the Next Decade? The Brutal Math of Consolidation – This strategic article delivers a stark, data-driven analysis of the industry’s accelerating consolidation. It provides a deeper understanding of the market forces that created the Norfolk disaster, outlining two primary survival strategies for farms: scaling up or pivoting to high-margin niche markets.

- The Tech Reality Check: Why Smart Dairy Operations Are Winning While Others Struggle – This piece on innovation provides a crucial reality check on technology adoption. It reveals the true ROI of investments like robotic milking and automated health monitoring, helping producers avoid common mistakes and strategically implement technology to slash labor costs and improve herd efficiency.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!