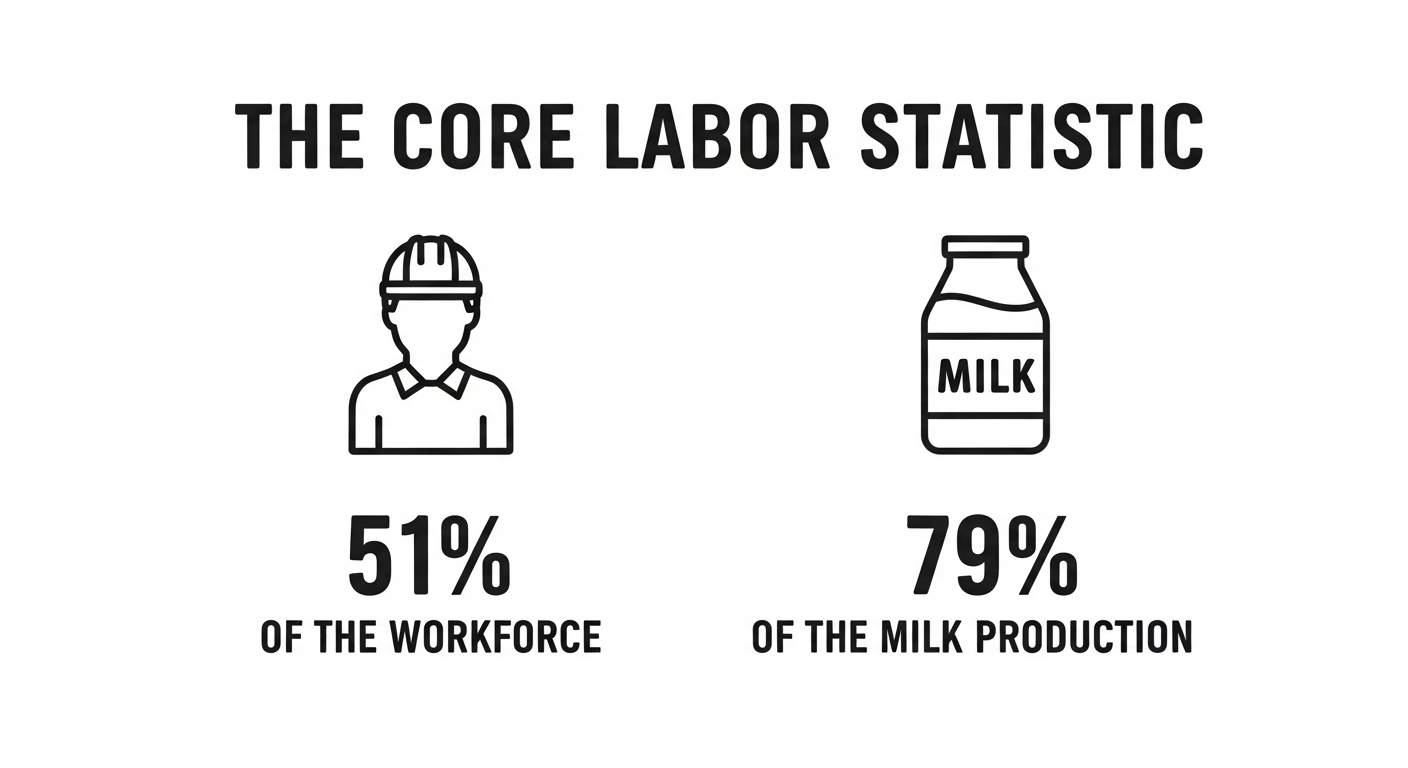

51% of dairy workers produce 79% of our milk – but Washington just changed the rules. Your automation ROI just got a lot more interesting.

EXECUTIVE SUMMARY: You know that gut feeling you’ve had about your labor situation? Well, it just got validated in the worst way possible. Washington’s “no amnesty” stance isn’t just policy talk—it’s about to reshape how every dairy operation thinks about their workforce and technology investments. Here’s what caught my attention: robotic milking systems that used to pencil out over 4-5 years are now showing 24-month paybacks under current labor market conditions. We’re talking about 21% labor cost reductions while some operations are seeing 8.9% production growth in states that still have reliable labor access. The producers who are already documenting their workforce and running new automation numbers aren’t just planning for 2026—they’re positioning themselves to dominate their local markets while their neighbors scramble to find milkers. This isn’t about replacing good people… it’s about creating systems that can thrive regardless of what Washington decides next.

KEY TAKEAWAYS

- Cut labor costs 21% with strategic automation – Robotic milking systems showing 24-month payback periods under current crisis conditions. Start documenting your recruitment costs, turnover expenses, and wage inflation now to run accurate ROI calculations.

- Workforce retention beats replacement every time – Operations implementing comprehensive benefit packages (including housing assistance) report turnover rates below 5% versus industry averages of 40%. This translates to $89,000 in avoided losses for a 1,000-cow operation.

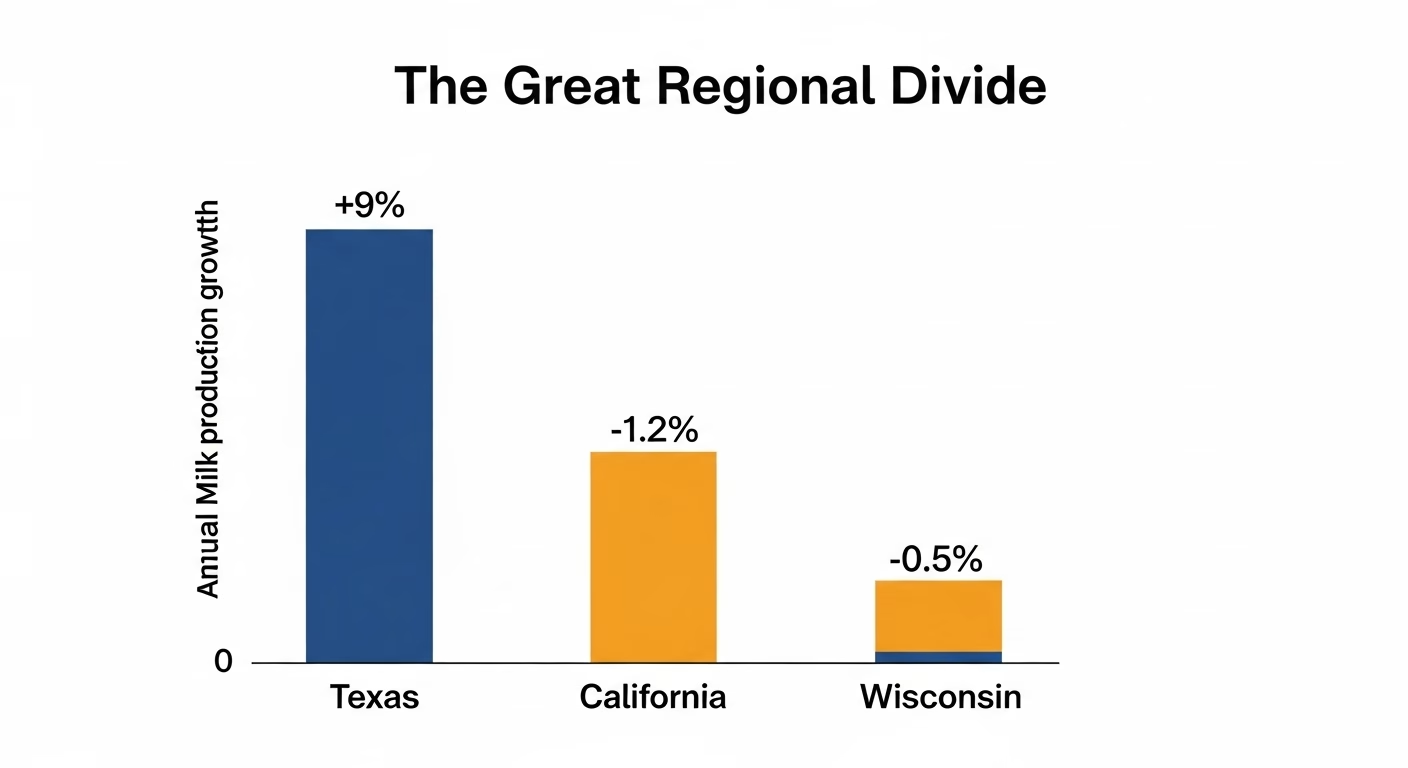

- Regional advantages are widening fast – Texas dairy operations showing 8.9% annual production growth while traditional dairy states face declining output. With Class III at $18.82/cwt and feed costs at $285/ton, your zip code is becoming your destiny.

- Document everything before you need it – Smart producers are formalizing HR processes and tracking worker histories now. When policy changes hit, the farms with proper documentation will have options while others face operational disruption.

- Technology adoption requires people strategy – Activity monitoring systems generating 3:1 ROI, but only when you’ve got skilled staff who can interpret the data. Cross-training and systematic workforce development are showing better returns than many technology investments.

You know what keeps me up at night lately? It’s not milk prices or feed costs, though those are gnawing at everyone. It’s this labor situation that’s about to reshape how we all do business.

The thing about Trump’s latest immigration stance is that it’s not just policy talk anymore. When the administration says “no amnesty” for ag workers while immigrant labor makes up 51% of our workforce but produces 79% of our milk… well, that’s your wake-up call right there. We’re talking about the backbone of American dairy production sitting in regulatory limbo.

What really gets me is how disconnected Washington seems from what’s happening in the milking parlor at 4 AM. But here’s the thing—we can’t wait for politicians to figure this out. The smart money is already moving, and if you’re not thinking three moves ahead, you’re going to get left behind.

The Policy Reality Check—And Why Your Morning Crew Matters More Than Ever

Agriculture Secretary Brooke Rollins dropped this gem in July: “34 million able-bodied adults in our Medicaid program” could fill farm jobs. I’ve been in this business long enough to know when someone’s never spent a morning in a dairy barn. Michael Marsh from the National Council of Agricultural Employers nailed it: “I just can’t imagine somebody from New York City wanting to take a job in upstate New York to milk a cow.”

That’s the disconnect we’re dealing with. Policy makers who think labor is interchangeable… like you can just swap out a skilled milker who knows your herd for someone who’s never seen a fresh cow.

The administration’s “temporary pass” program? Still completely undefined. Labor Secretary Lori Chavez-DeRemer announced a new Department of Labor agricultural office, but honestly, that’s bureaucratic speak for “we’re still figuring this out.” Try planning your 2026 budget with that kind of clarity.

Here’s what’s really happening, though, and this is where it gets interesting for those of us actually running operations…

The Numbers Game—And Why Geography Is Becoming Destiny

Let’s talk about what this means for your bottom line, because the regional differences are getting stark. Wisconsin’s sitting on 2,800 H-2A workers for seasonal work, but dairy? We’re locked out because the program only covers “temporary or seasonal” work. Try explaining that to a cow that needs milking 365 days a year.

The University of Wisconsin-Madison folks have documented that about 70% of Wisconsin’s dairy workforce comes from immigrant labor. That’s roughly 10,000 workers in Wisconsin alone. Now imagine what happens if enforcement ramps up…

I was just talking to a producer in Fond du Lac County who’s been milking 800 head for fifteen years. Same crew, same routine, same quality. He told me, “Andrew, I don’t know what I’d do if I lost even two of my key guys.” That’s the reality we’re dealing with.

California’s already feeling the squeeze. Despite pumping out 40.1 billion pounds annually, they’re seeing production slip while labor costs jump 4% year over year. With Class III averaging $18.82 per hundredweight—and that’s before you factor in this summer’s volatility—those margins are getting tight.

But here’s what’s fascinating: Texas is telling a completely different story—8.9% annual production growth because they can still access reliable labor. The competitive gap is widening, and your zip code is starting to matter more than your management skills.

The Automation Play—When $275,000 Starts Looking Like Insurance

So what do you do when your labor pool is sitting on political quicksand? The answer I’m seeing more and more is defensive automation.

Robotic milking systems that cost $150,000 to $275,000 per unit are now showing payback periods under two years. Two years! That’s unheard of under normal market conditions, but we’re not dealing with normal anymore, are we?

I was just out at a 500-cow operation in Lancaster County that installed their first two robots last spring. The owner—let’s call him Jim—told me something that stuck: “I didn’t buy these because I wanted to. I bought them because I had to.” His labor costs dropped 23% in the first year, but more importantly, he’s sleeping better at night.

Recent work from Cornell on automated milking shows labor costs dropping over 21% once you get the systems dialed in. But here’s the kicker—58% of adopters report higher milk production, while only 54% would actually recommend the technology. That tells you everything about the learning curve.

What’s particularly noteworthy is how these systems change your labor needs rather than eliminating them. Those activity monitoring systems that run about $150 per cow are showing 3:1 returns when you’ve got someone who actually knows how to read the data. The keyword there is “someone”—you still need skilled people, just different skills.

The Real Cost of Standing Still

Here’s where it gets uncomfortable for a lot of producers. Current financing isn’t exactly farmer-friendly—prime rates at 8.5% and equipment financing pushing 10-12% for qualified borrowers. That changes your payback calculations significantly.

But the cost of doing nothing? That’s where the numbers get scary. Recent research documented in Progressive Dairy shows that high-turnover operations are seeing 1.8% production drops, 1.7% higher calf mortality, and 1.6% more cow deaths. For a 1,000-cow operation, that’s roughly $89,000 in lost revenue… and that’s before you factor in quality penalties from elevated somatic cell counts.

I ran the numbers for a typical 500-cow operation considering robotic milking. Break-even at 24 months under current labor market conditions. If wage pressure eases—and honestly, when’s the last time you saw that happen?—it extends to 36 months. But that’s assuming you can find and keep good people.

The thing about automation failures, though… Progressive Dairy’s implementation studies show 15-20% failure rates within the first 18 months. Usually comes down to inadequate preparation or unrealistic expectations. This isn’t plug-and-play technology—it’s a complete operational shift.

What’s Actually Working—The Retention Success Stories

The producers who are crushing it right now aren’t just throwing money at robots. They’re getting strategic about their people.

I know a 650-cow operation in Sheboygan County that’s reporting 3% annual turnover. How? Comprehensive benefit packages include housing assistance. They built four modest houses on the property—nothing fancy, but clean, safe, and affordable. Their labor costs per cow are actually below the regional average because they’re not constantly training new people.

This development is fascinating—structured training programs documented in the Journal of Dairy Science show measurable improvements in both knowledge retention and actual performance metrics. But it requires real investment. We’re talking curriculum development, dedicated training time, and—this is crucial—making sure your existing crew buys into teaching newcomers.

The financial impact is quantifiable. Low-turnover operations avoid those production drops, quality issues, and constant recruitment costs. It’s becoming a competitive advantage that compounds over time.

Regional Realities—Why Your Neighbors Matter More Than Washington

What’s happening in the Upper Midwest versus the Southwest is like watching two different industries. Wisconsin and Minnesota producers are feeling the squeeze because they’ve been more dependent on immigrant labor without the policy flexibility that border states might have.

I was talking to a producer in New Mexico last month who told me, “We’ve always had to be more creative about labor.” Different regulatory environment, different labor pool, different strategies. But even they’re concerned about what happens if federal enforcement ramps up.

Feed costs are running about $285 per ton for quality hay across most regions—that’s up from $260 last year—but the labor availability gives certain areas a significant edge in total production costs. The most competitive operations are maintaining labor costs under $4 per hundredweight, but that benchmark is getting harder to hit.

Here’s what’s really interesting: the operations that are thriving aren’t necessarily the biggest or the most high-tech. They’re the ones that figured out how to create workforce stability in an unstable environment.

The Skills Evolution—What Tomorrow’s Dairy Workers Look Like

The labor conversation is evolving beyond just finding bodies to move. Activity monitoring systems and precision feeding technology are creating demand for workers who can interpret data, rather than just following a routine.

I’ve been watching this trend for about three years now. The farms that are succeeding with technology adoption are the ones that invested in their people first. Cross-training, systematic development, creating advancement opportunities… it’s not just good management anymore, it’s a survival strategy.

What strikes me about the successful operations is how they’re treating their workforce as a competitive advantage rather than a cost center. One producer in Minnesota told me, “My cows are good, but my people are what make the difference.” That’s the mindset shift we need to see more of.

The Bottom Line—What You Actually Need to Do

Look, I’m not going to sugarcoat this. If you’re waiting for Washington to solve your labor problems, you’re going to be waiting a long time. Here’s what I’m seeing work:

Start documenting everything now. Worker histories, wage progression, training records, performance metrics. This isn’t just good HR—it’s positioning yourself for whatever policy changes come down the pike. The operations that can demonstrate their value to both workers and regulators will have options.

Run new automation numbers. Those ROI calculations from two years ago? Toss them. Current recruitment costs, turnover expenses, and wage inflation change everything. You might be surprised what pencils out now.

Invest in your people before you replace them. The farms that are winning aren’t just buying technology—they’re creating cultures where good people want to stay. That means competitive benefits, advancement opportunities, and treating your crew like the professionals they are.

Think regionally, not nationally. Your local labor market conditions matter more than whatever’s happening in Washington. Build relationships with other producers, share strategies, and create networks that can weather policy uncertainty.

This isn’t just about surviving policy changes—it’s about building operations that can thrive regardless of what happens in Washington. The farms that start positioning themselves now will be the ones still milking cows in 2030.

And honestly? That’s probably the way it should be. We can’t control Washington, but we can control how we respond to it. The question is: are you going to lead this transformation or get dragged along by it?

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- How to Attract and Retain Exceptional Labor for Your Dairy Farm – Discover proven retention strategies that slash turnover from 40% to under 5%, including hands-on training programs and mentorship systems that transform your workforce into a competitive advantage.

- Here’s the Hard Truth About Labor Reform: Why the Farm Workforce Modernization Act Could Finally Fix Your Biggest Headache – Reveals how FWMA’s year-round H-2A visa access and 3.25% wage caps could reshape your labor costs and ROI calculations for automation investments.

- Crushing the Labor Crisis: How Smart Dairies Transform Recruiting into a $50K+ Annual Advantage – Demonstrates innovative recruiting methods that expand your talent pool by 300% through skills-based hiring and technology-focused job positioning that attracts non-traditional candidates.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!