AI feeding saves $31/cow while your neighbors debate whether it works—Cornell proves 95% accuracy in detecting sick cows before you see symptoms.

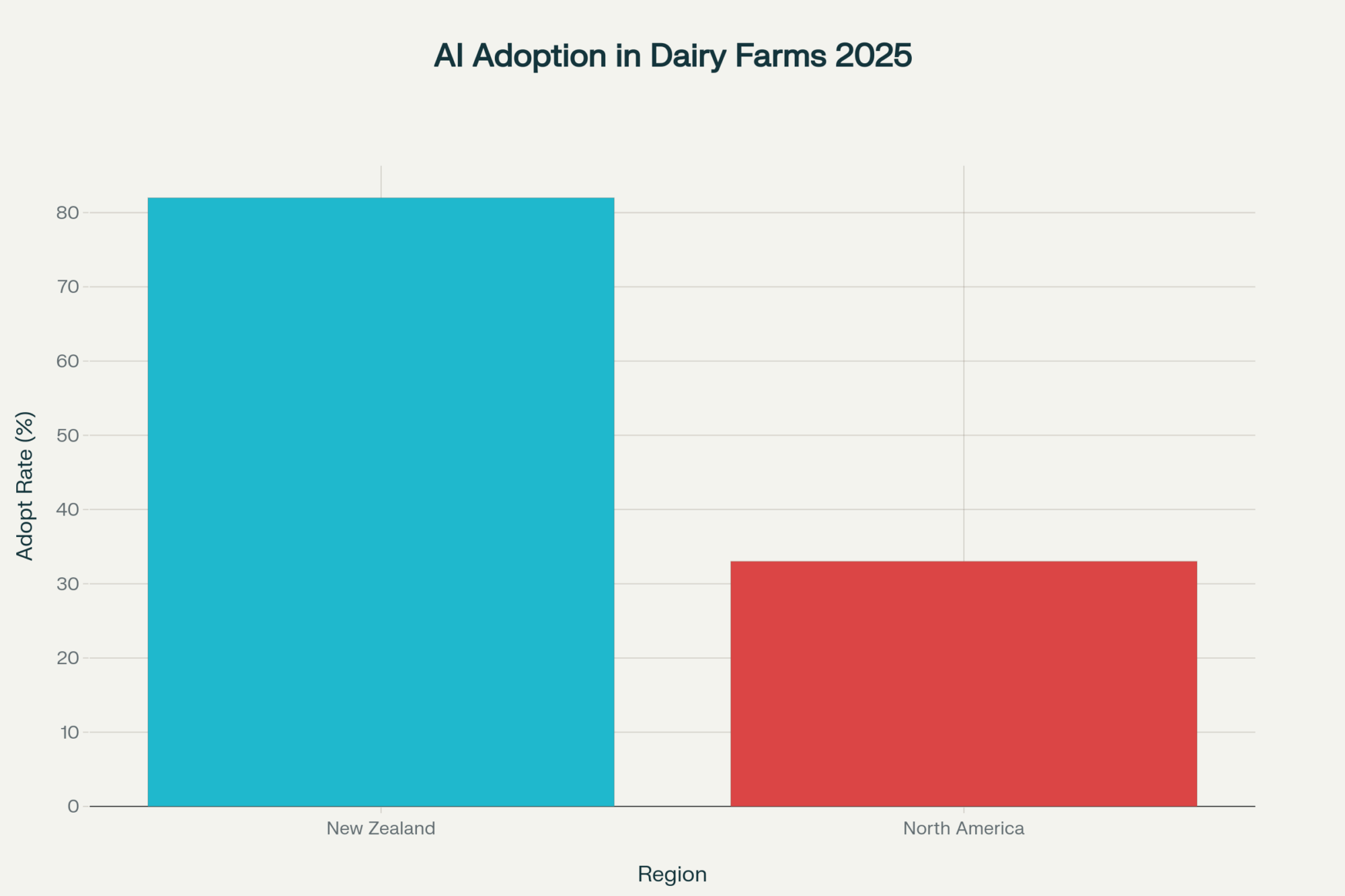

EXECUTIVE SUMMARY: Listen, I’ve been watching this AI thing unfold for months, and here’s what’s actually happening… Progressive operations are generating $210 per cow annually by allowing technology to handle monitoring, while they focus on strategic decisions. We’re talking real money here—Wisconsin producers hitting 30% pregnancy rates, California farms cutting mastitis by 40% in year one. The University of Wisconsin documented $31 per cow from smarter feeding alone, and Cornell has proven 95% accuracy in catching metabolic problems before even the best cowman would notice. In New Zealand, 82% of dairies are already using this technology, while we’re at around 30% adoption. Look, I get the hesitation—40% of projects fail because farms skip the training or try to do too much too fast. But are the farms getting it right? They’re not just surviving tight margins; they’re thriving in them.

KEY TAKEAWAYS

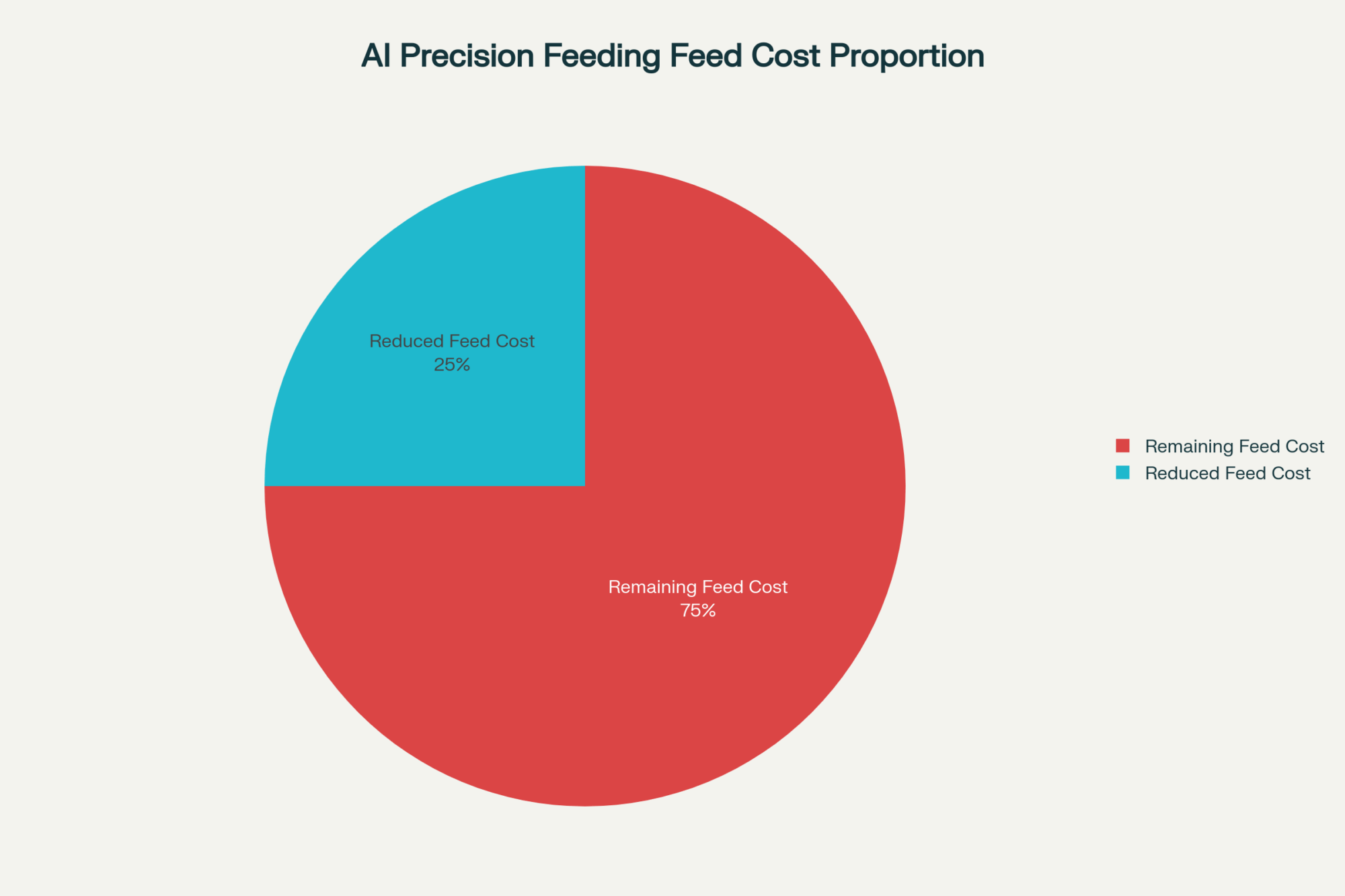

- Start with feeding optimization — AI-driven precision feeding delivers $31 annual savings per cow through reduced waste and better ration management. Pilot test on 10-20% of your herd this fall when feed costs matter most.

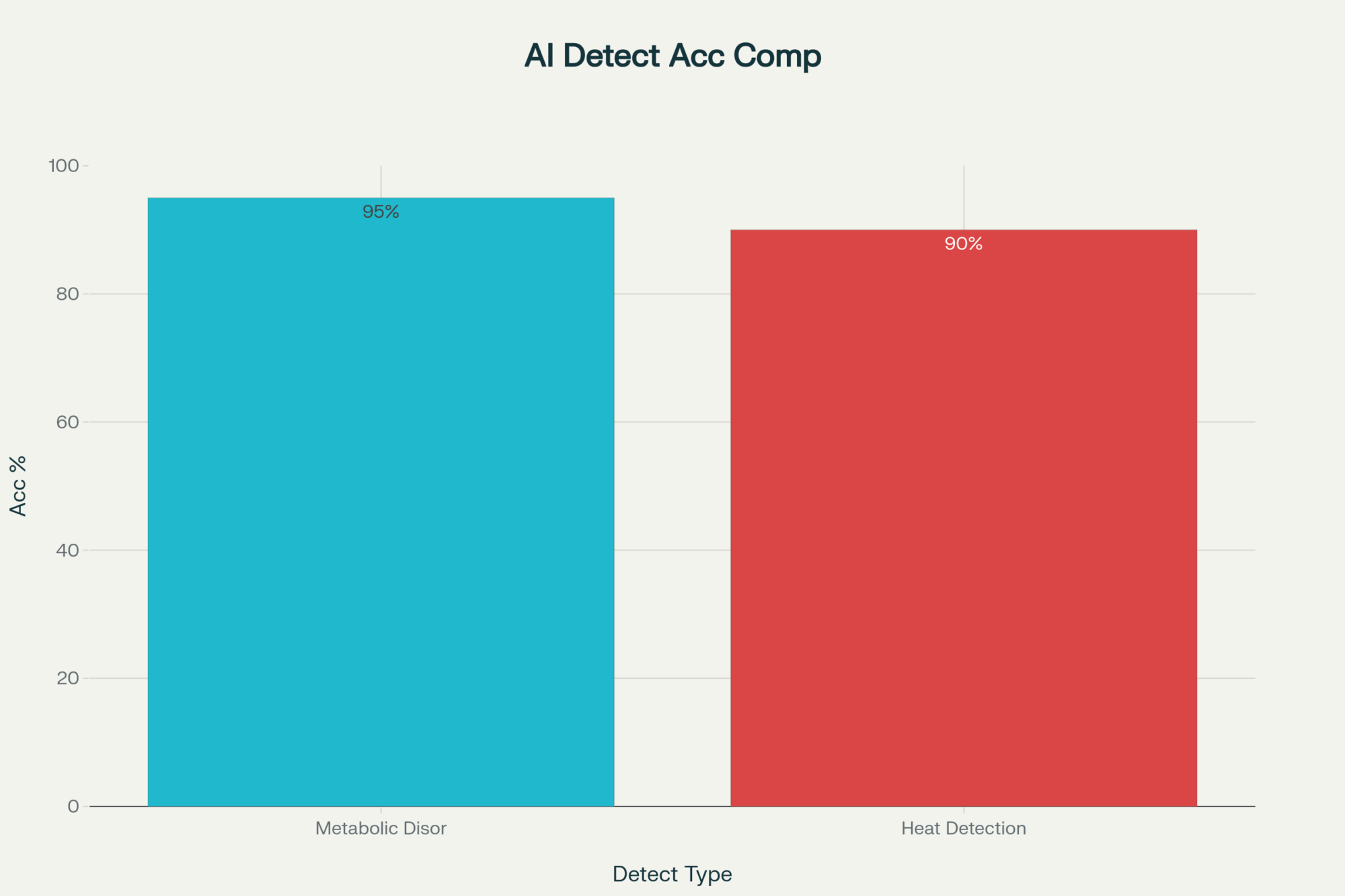

- Early disease detection pays off big — Cornell research shows 95% accuracy in spotting metabolic disorders days before clinical symptoms appear. That’s $65 saved for every day you catch mastitis early; plus, the milk you don’t lose.

- Heat detection accuracy jumps to 90% — University of Guelph data confirms 30% better pregnancy rates with AI monitoring versus traditional methods. With breeding costs what they are, that ROI calculation writes itself.

- Scale matters for success — Operations with 300-1000 cows hit 80-90% implementation success rates. If you’re in that sweet spot, the infrastructure investment makes sense with the current 7.2% loan rates.

- Budget beyond equipment costs — Plan 20-30% extra for training and integration support. The farms that skimp on staff education are the ones hitting those 40% failure rates everyone talks about.

The thing about dairy farming is, we’ve always relied on good instincts—your grandfather’s watchful eye, that feeling you get walking through the barn at dawn. However, what I’m witnessing across leading operations from Wisconsin to California is that the sharpest producers are blending those time-tested instincts with some compelling data. And, man, the results are showing up where they count most.

Take feeding, for instance. Producers are banking around $31 per cow annually just by letting AI fine-tune their feeding programs, according to recent work from the University of Wisconsin’s Dairy Brain Initiative. That’s not marketing fluff—that’s actual cash reclaimed from smarter rations and cutting waste where it hurts most.

Picture this: milk has been sitting steady near $18.85 per hundredweight this July, as reported by the USDA Agricultural Marketing Service, while corn futures hover around $4.30 per bushel on the CME Group. Every penny you can squeeze out of feed efficiency… well, it adds up faster than you’d think.

The Market’s Speaking Volumes

Here’s what catches my attention: the precision livestock farming market has officially crossed $5.59 billion worldwide, according to the “Precision Livestock Farming Market Report (2025)” by Market Research Future. That kind of momentum doesn’t happen because farmers love shiny tech toys—it happens because there’s real value being captured.

At last year’s Canadian XPO, Jack Rodenburg from the University of Guelph put it perfectly: “You can’t watch every cow all the time when you’ve got hundreds in the barn. AI systems are like having that one employee who never takes a coffee break, spotting those subtle changes we sometimes miss.”

Cornell’s study “Detection of Subclinical Diseases Using AI,” published in the Journal of Dairy Science (Vol. 108, Issue 2), backs this up—AI models are hitting 95% accuracy in detecting metabolic disorders before we’d ever spot them during morning rounds. That’s the kind of edge you can’t ignore.

The Mastitis Math Nobody Wants to Do

We’ve all been there—felt the sting of a mastitis case that slipped past us. Michigan State University Extension research drives the point home: every day you delay treatment; you pay an average of $65 extra. Early detection through AI sensors literally reclaims those expensive days.

Here’s something that keeps coming up in conversations… there’s this noticeable split in adoption rates globally. New Zealand’s way out in front, with 82% of dairies embracing AI technology, according to DairyNZ’s 2025 industry data. In contrast, here in North America, depending on your region and operation size, we’re looking at somewhere around 25-35%.

That gap represents an opportunity—and a competitive advantage being captured while others debate implementation costs.

The composite picture is compelling: operations leveraging AI report profit boosts averaging $210 per cow annually, according to IFCN’s 2025 economic analysis report. This isn’t the $31 feeding savings stacked on top of other benefits—it’s the total lift from better feeding, health monitoring, and reproductive management working together.

With operating loans currently averaging around 7.2%, as reported by the Federal Reserve Bank of St. Louis, faster payback periods are more important than they were in the past.

Feed Efficiency That Actually Moves Numbers

Digging deeper into the nutritional aspect, Spanish researchers at IRTA have shown that operations can reduce feed costs by approximately 25% without compromising production. When you think about corn, silage, and supplement price volatility—especially with the weather patterns we’ve been seeing—that kind of precision really matters.

Heat detection’s where things get really interesting. The University of Guelph’s reproductive research program reports that AI is increasing detection accuracy from around 55% to 90%, resulting in a roughly 30% improvement in pregnancy rates. Those are the kinds of numbers that change your whole breeding program.

What Real Farms Are Actually Seeing

I can’t name specific operations—farmers rightfully keep some cards close to their vest—but Wisconsin producers I’ve spoken with mention achieving 30% pregnancy rates after integrating comprehensive monitoring systems. These are sharp operators who’ve figured out how to let the data enhance their barn sense, not replace it.

Down in California’s Central Valley, dairy farmers report solid 7% production increases alongside a nearly 40% reduction in mastitis cases in their first year with AI support. Real, tangible impacts you can take to the bank.

In Europe, Austrian cooperatives using SmaXtec technology report substantial operational savings, although exact figures are kept confidential due to non-disclosure agreements.

Size Clearly Influences Success Rates

Farm size drives implementation success in ways you’d expect. Operations with 300 to 1,000 cows consistently hit 80-90% success rates with these systems, according to data from Agricultural Economics Research International—a clear reflection of scale economics and infrastructure capabilities.

Robotic milking keeps building momentum. University of Minnesota Extension research documents $30,000 to $45,000 in annual labor savings per robot—but here’s the reality check: maintenance and energy costs can tack on another $5,000 to $25,000 each year. Budget accordingly.

The latest vision technology, utilizing advances such as YOLOv9 algorithms, now achieves 90% accuracy in identifying health issues, even in the chaos of a working barn, according to presentations at the 2025 AI for Agriculture Symposium.

The Reality Check You Need to Hear

Here’s what nobody talks about enough: industry consultants at the Agricultural Economics Institute estimate that roughly 40% of AI projects fail to deliver expected returns, usually due to integration problems or a lack of ongoing support after the sale.

Even more concerning? Technology audits reveal that only about 5% of available AI tools have undergone rigorous, independent validation. That’s a red flag for doing your homework on suppliers.

Jeffrey Bewley at the University of Kentucky Extension nails the core issue: “AI amplifies what you’re already doing right, but it won’t patch up fundamental management problems.”

What Actually Works in Practice

My take? Start small and scale smart. Test AI applications on a subset of your herd first—health monitoring or reproductive management work well as pilots. Get your team appropriately trained… extension services consistently report that operations that skimp on training hit roadblocks they could’ve avoided.

Before jumping in anywhere, establish clear baselines. Track your current mastitis treatment costs, feed conversion efficiency, and reproductive performance metrics. Without baseline data, you’re flying blind on measuring real impact.

The Future That’s Already Starting

What gets me excited is watching how AI, genetics data, and nutritional management are starting to weave together. We’re moving beyond individual tools toward integrated decision-making systems that learn your operation’s unique patterns and challenges.

The bottom line? Operations that feed precisely, monitor continuously, and act early on problems are consistently outperforming traditional approaches. The competitive advantage is becoming measurable and sustainable.

If you haven’t started exploring these technologies, today might be a good day for a conversation with your county extension agent or established technology providers. Ask the hard questions about training, support, and realistic implementation timelines. What’s the one area on your farm where you think data could make the biggest difference?

Because really, the best time to plant that tree was twenty years ago. The second best time is today.

Your cows are generating data every minute, whether you use it or not. The question is whether you’ll let that information work for your operation’s future.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The 7 Habits of Highly Effective Robotic Milking Herds – Go beyond the purchase price with this tactical guide. It reveals the essential management protocols that top producers use to maximize milk output and herd health in an automated milking environment, turning your technology investment into a true profit center.

- The 8 Profitability Metrics That Define Success in Today’s Dairy Industry – This strategic overview breaks down the key financial metrics that separate profitable dairies from the rest. Learn to analyze your operation’s performance beyond milk price, giving you a powerful framework to measure the true impact of your technology investments.

- Genomics: The Crystal Ball That’s Reshaping the Dairy Industry – Look beyond operational AI and into the future of herd improvement. This piece details how genomic testing provides predictive insights to accelerate genetic gain, reduce disease risk, and build a more profitable and resilient herd for the next decade.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!