From recordbooks to revenue: the quiet revolution paying off for data‑driven dairy farms.

Executive Summary: Across the country, producers are realizing that clean data is money in the bank. Europe might have built its sustainability systems first, but American dairies already outperform them in efficiency—you just have to prove it. The FARM Environmental Stewardship Version 3 program, aligned with the international Greenhouse Gas Protocol, makes that proof easy with records you already keep. Verified data now pays through carbon‑credit sales, 45Z clean‑fuel incentives, and better financing rates. The payoff isn’t futuristic—it’s here. For farms that treat recordkeeping with the same discipline as herd health, verified sustainability turns daily management into measurable profit.

Suppose you’ve been at a milk meeting or leaned on the gate with a neighbor lately. In that case, sustainability has probably come up—carbon markets, data verification, maybe the buzz around “net-zero milk.” And someone almost always says, “Europe’s ahead of us.”

That’s partly true. Europe’s been building sustainability frameworks for over a decade. FrieslandCampina’s Climate Plan, for example, now involves more than 11,000 member farms tracking emissions performance, and Ireland’s Origin Green program—run by Bord Bia—includes about 99 percent of national dairy herds. Those systems tie data verification directly to milk pay.

But here’s what’s interesting: America’s dairymen are already leading on the production side. USDA and FAO data confirm that U.S. cows produce roughly four times the global average milk yield per animal while maintaining a carbon footprint about half the world average. Efficiency, genetics, and feed science have taken us quietly to world-class performance; we just haven’t documented it in a way global buyers recognize.

And with that documentation increasingly tied to future premiums, the advantage is ours to capture—if we move now.

Europe’s Model—and Why Our Playbook Can Be Faster

Europe’s systems rely on national policy, multi-agency oversight, and cooperative mandates. They deserve credit for structure but pay a price in speed. American farms, with their flexibility and drive for innovation, can get results faster by using voluntary systems that meet the same verification standards.

| Factor | European Model | American Model |

| Implementation | National policy mandates | Voluntary market-driven ✓ |

| Speed to Market | 10+ years to build | 2-3 years active ✓ |

| Farmer Flexibility | Lower (mandatory) | Higher (opt-in) ✓ |

| Farmer Cost | Covered by co-op ✓ | $0-500 one-time ✓ |

| Coverage Rate | 99% (Ireland), 11,000+ farms ✓ | Growing rapidly |

A good starting place is the FARM Environmental Stewardship Version 3 (FARM ES) program from the National Milk Producers Federation, built to align with the Greenhouse Gas Protocol that global processors and brands already trust. It takes information most farms already manage—herd size, milk sold, feed rations, energy use, and manure plans—and converts it into a certified emissions profile.

The surprising thing? It’s not expensive. Many co‑ops provide FARM ES audits at no cost, and independent producers pay roughly what they’d make off one cull cow. For that effort, a farm gains new eligibility for financial and marketing benefits that will matter more every year.

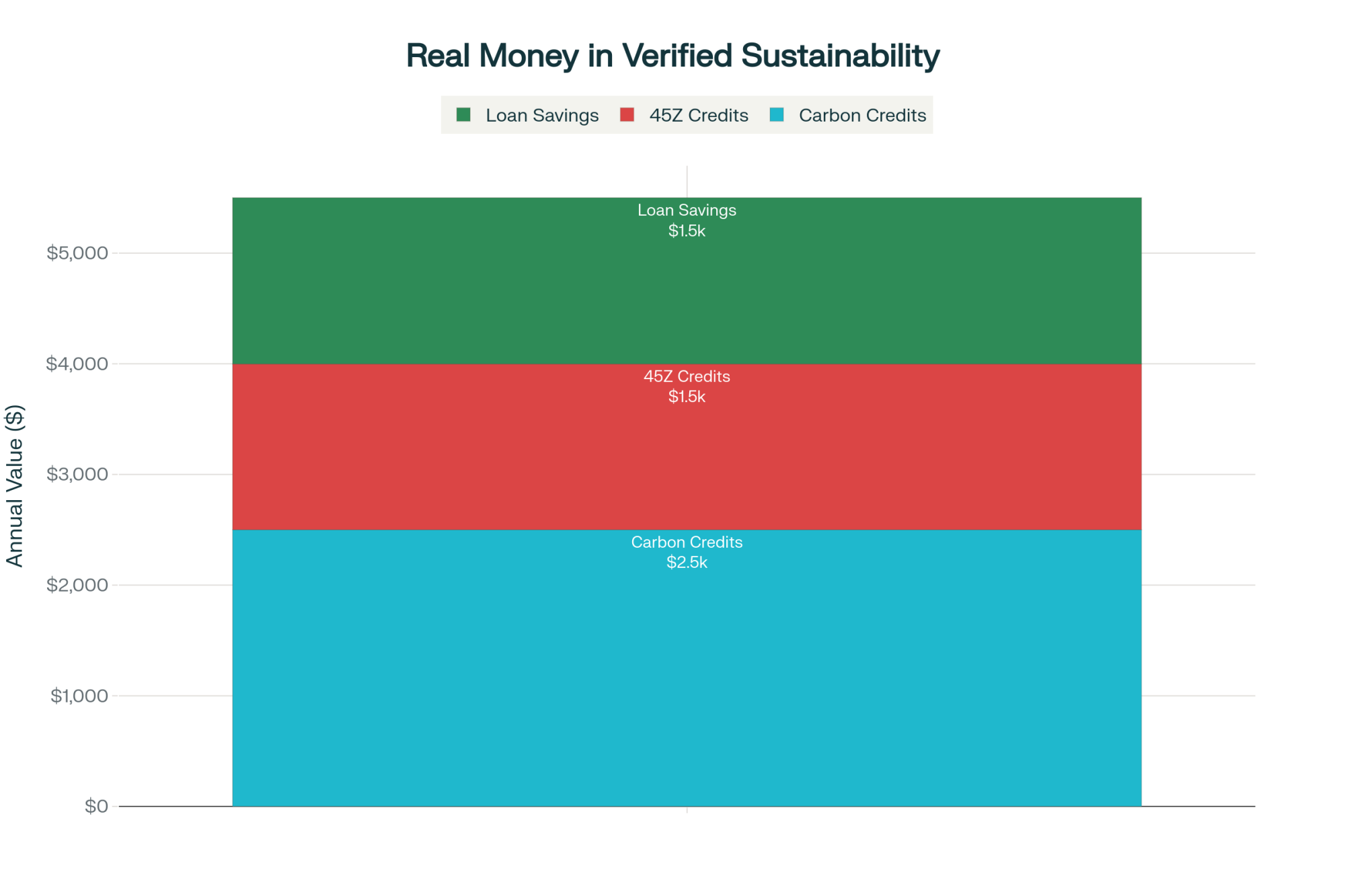

The Financial Benefits

1. Carbon Markets

The Athian Marketplace certifies U.S. livestock emission reductions and has paid between $15 and $35 per metric ton of CO₂ equivalent, depending on verification costs. Because Athian’s model passes roughly 75 percent of each credit’s value back to the farm, producers keep the majority of the payout.

2. Federal Incentives

The 45Z Clean Fuel Production Credit pays for verifiable reductions in carbon intensity—not acres or estimates, but actual farm numbers. Feed and manure efficiencies documented through FARM ES can qualify as part of these performance‑based credits.

3. Financing Leverage

Lenders like CoBank and Farm Credit Council are piloting sustainability‑linked loans that reduce interest rates for verified operations. A FARM ES audit doesn’t just help with policy—it can make capital cheaper.

Together, these programs show how verified data shifts from compliance paperwork to productive income. One organized afternoon can turn recordkeeping from routine into return.

Why Some Tech Never Delivers ROI

Many of us have watched a promising piece of farm technology fizzle. The problem often isn’t the device—it’s the data.

A 2024 Journal of Dairy Science study found that about 70 percent of U.S. dairies adopting new digital systems didn’t hit ROI targets in the first 18 months, mainly due to incomplete or inconsistent data. One feeder logs as‑fed weights while the nutritionist records dry matter. Treatments get entered late. Before long, the system’s analytics are unreliable, and confidence fades.

University of Wisconsin Extension specialists remind producers that digital accuracy depends on analog habits. Just as inconsistent milking prep ruins routine, inconsistent data entry ruins results. The farms that use tech profitably treat recordkeeping like herd health: daily, disciplined, verified.

Mindset Over Machinery

Paul Windemuller, a Michigan producer and 2024 Nuffield Scholar, puts it plainly: “Technology should strengthen what good farmers already do well—not take over their jobs.”

Windemuller’s international research—shared at the IDF World Dairy Summit—found that farms using automation to amplify stockmanship saw higher ROI than those expecting machines to replace experience. It’s a point echoed by researchers at the University of Agricultural Sciences (Sweden) and Danish Extension: operations treating technology as an extension of stockmanship achieved better herd health, higher butterfat stability, and lower labor turnover.

It all comes back to mindset. The best farms use technology to earn back time—not give it away to screens. They don’t chase innovation for its own sake—they fit it to their team and goals.

The 70/30 Success Pattern

Out of hundreds of farms tracked in adoption studies, about 30 percent achieve sustained ROI from dairy technology. Their success habits share a pattern:

- Start simple. Focus on one clear metric—say, butterfat‑to‑protein ratio or feed conversion—and master it before adding more.

- Assign accountability. One “data captain” ensures consistency across team members.

- Expect lag time. Smaller herds might need 6–9 months to reach stable results; larger herds, a full year.

- Link systems. Connecting herd, feed, and parlor software reduces manual entry errors by 40–50 percent, according to UW Extension research.

These behaviors create measurable gains. Annual feed savings typically range from $10 to $15 per cow, often achieved before new hardware is installed.

Why U.S. Dairies Can Move Faster

Europe’s verification model rewards patience; ours rewards practicality. Because private‑sector partnerships drive most American initiatives, change happens barn‑by‑barn instead of country‑by‑country.

Some examples already proving useful:

- Athian Marketplace, a carbon exchange explicitly designed for livestock, keeps most income on farms.

- Milk Sustainability Center, built by John Deere and DeLaval, links soil, feed, and milk data in one platform.

- Farm‑Twin, from Scotland’s Rural College, is open‑source and now adapted for North American dairies to simulate feed or manure outcomes before investing.

These tools work exactly where many producers excel—through efficiency and autonomy.

Your First Step

If you want to get started quickly, schedule a FARM ES assessment. Almost everything you need—DHIA production data, feed summaries, herd inventories, energy records, and manure plans—is already in your files. For most farms, the process takes half a day.

Midwest pilot programs in 2024 showed farms completing verification in a single session. One co‑op manager summed it up best: “It’s not about being perfect—it’s about documenting progress.” Those verified numbers can then be applied to farm loans, processor requirements, or carbon credit programs with confidence.

Consistency Outperforms Complexity

Veteran producers remember when DHIA testing was “extra work.” Now, you wouldn’t run a herd without it. Data verification will follow the same curve.

From Wisconsin free‑stalls to California dry lots to Vermont pasture systems, farms that treat recordkeeping as another layer of herd health management are already ahead. Clean data isn’t bureaucracy—it’s evidence of good farming.

The Bottom Line

Technology doesn’t make great dairies—people do. The producers pairing their practical know‑how with verifiable data are defining what’s next. Verification isn’t red tape; it’s a receipt for the hard work this industry has already done to feed the world efficiently and responsibly. And now, we get to prove it.

Key Takeaways

- Across the U.S., farms are learning that clean, consistent data turns management into money—through carbon markets, 45Z credits, and low‑interest loans.

- FARM Environmental Stewardship Version 3 helps producers prove what they already do well, using herd records, feed sheets, and energy logs they already track.

- American dairies outperform Europe on efficiency; now it’s time to put those numbers to work.

- The best ROI in technology isn’t from buying more—it’s from managing better.

- Producers who verify now will set the standard, earning sustainability premiums while strengthening dairy’s public trust.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The Carbon Credit Programs Every Dairy Should Join Before 2026 – This strategic analysis expands on the financial incentives by detailing actual carbon revenue streams, providing specific return figures (up to $450 per cow), and revealing the crucial differences between voluntary and compliance markets. It offers deep economic context for the sustainability verification advocated in the main article.

- Tech Reality Check: The Farm Technologies That Delivered ROI in 2024 (And Those That Failed) – This innovation-focused piece provides specific performance metrics for technology like robotic milkers, demonstrating with hard data why top-performing farms achieve 42% more output than struggling operations. It complements the “Mindset Over Machinery” section by showing precisely how execution drives or destroys ROI.

- From Data to Dollars: Small Steps to Maximize Dairy Profits Through Accurate Herd Management – This tactical article provides actionable implementation steps, demonstrating how common data entry errors (e.g., missed dry-off lists or wrong pen counts) cascade into costly mistakes. It provides the “how-to” guide for achieving the data discipline foundational to both technology ROI and FARM ES success.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!