One million U.S. cows are under AI surveillance—and they’re making 20% more milk. Here’s how.

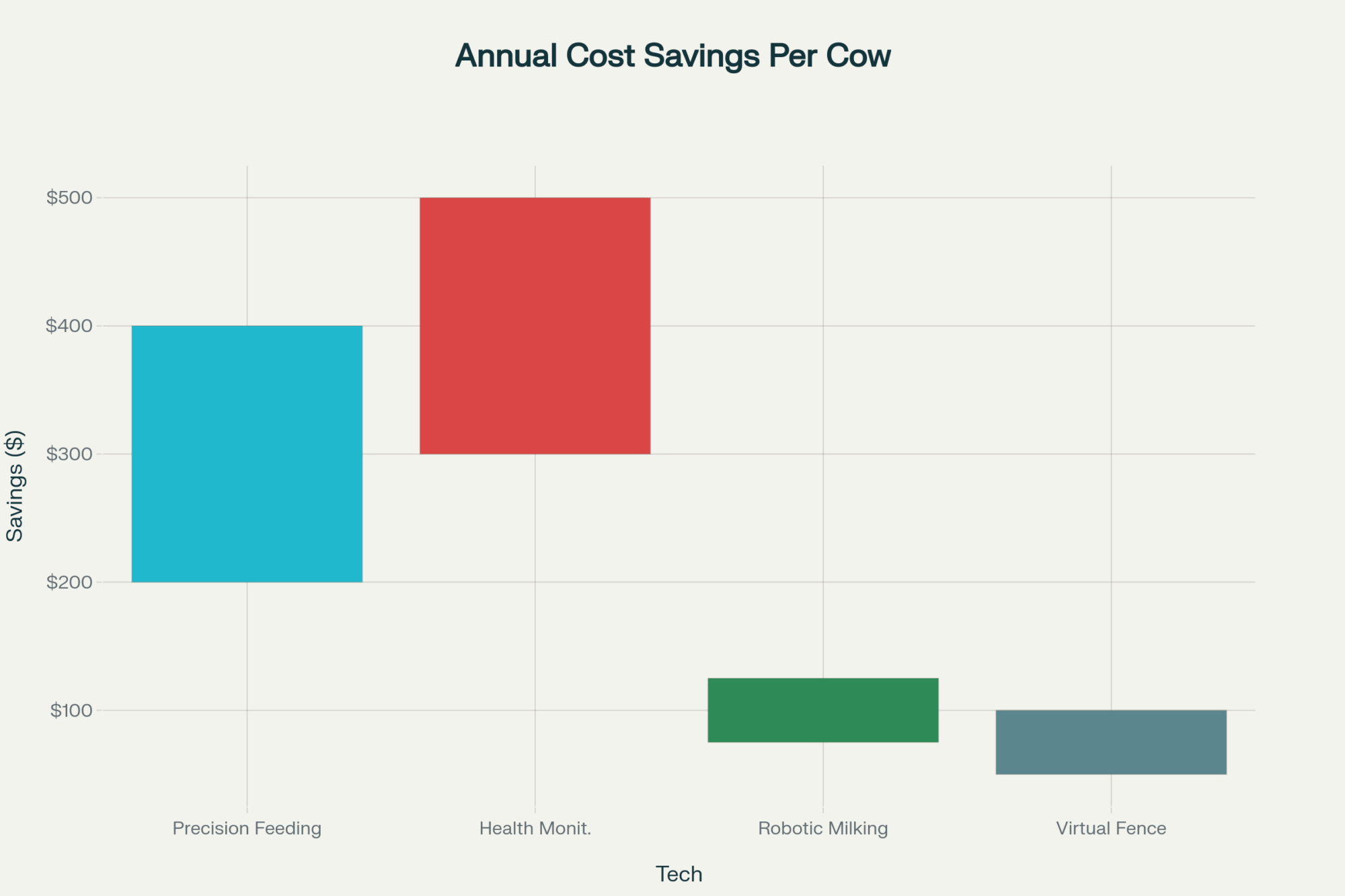

EXECUTIVE SUMMARY: Look, I’ve been saying this for years—the old “gut feeling” approach to dairy management is done. The farms crushing it right now are using precision tech to slash input costs by 25% while boosting milk yields 10-20%, and it’s not just the mega-dairies doing it. We’re talking real money here: $200-400 per cow in feed savings, plus another $300-500 saved on vet bills when you catch lameness early. The numbers from North America and Asia indicate that these technologies pay for themselves in 2-4 years, even with milk prices fluctuating around $18 per hundredweight. Small farms, big farms—doesn’t matter. What matters is selecting the right technology for your setup and actually utilizing it. Bottom line? If you’re not at least exploring this area, you’re leaving significant money on the table while your competitors pull ahead.

KEY TAKEAWAYS:

- Cut feed costs 15-25% — Start with precision feeding systems that optimize your TMR and individual cow rations. With feed making up 50-60% of your expenses, better feed conversion efficiency isn’t a nice-to-have anymore—it’s a matter of survival in 2025’s tight margins.

- Boost milk yield 10-20% — Robotic milking systems keep your protocols consistent and reduce cow stress through more frequent milking. Labor shortages aren’t improving, so implementing solid milking protocols via automation makes financial sense now.

- Save up to $500 per cow on health costs — AI-powered lameness detection and reproductive monitoring catch problems before they cost you big. With vet bills climbing and animal welfare scrutiny increasing, automated health monitoring is becoming essential.

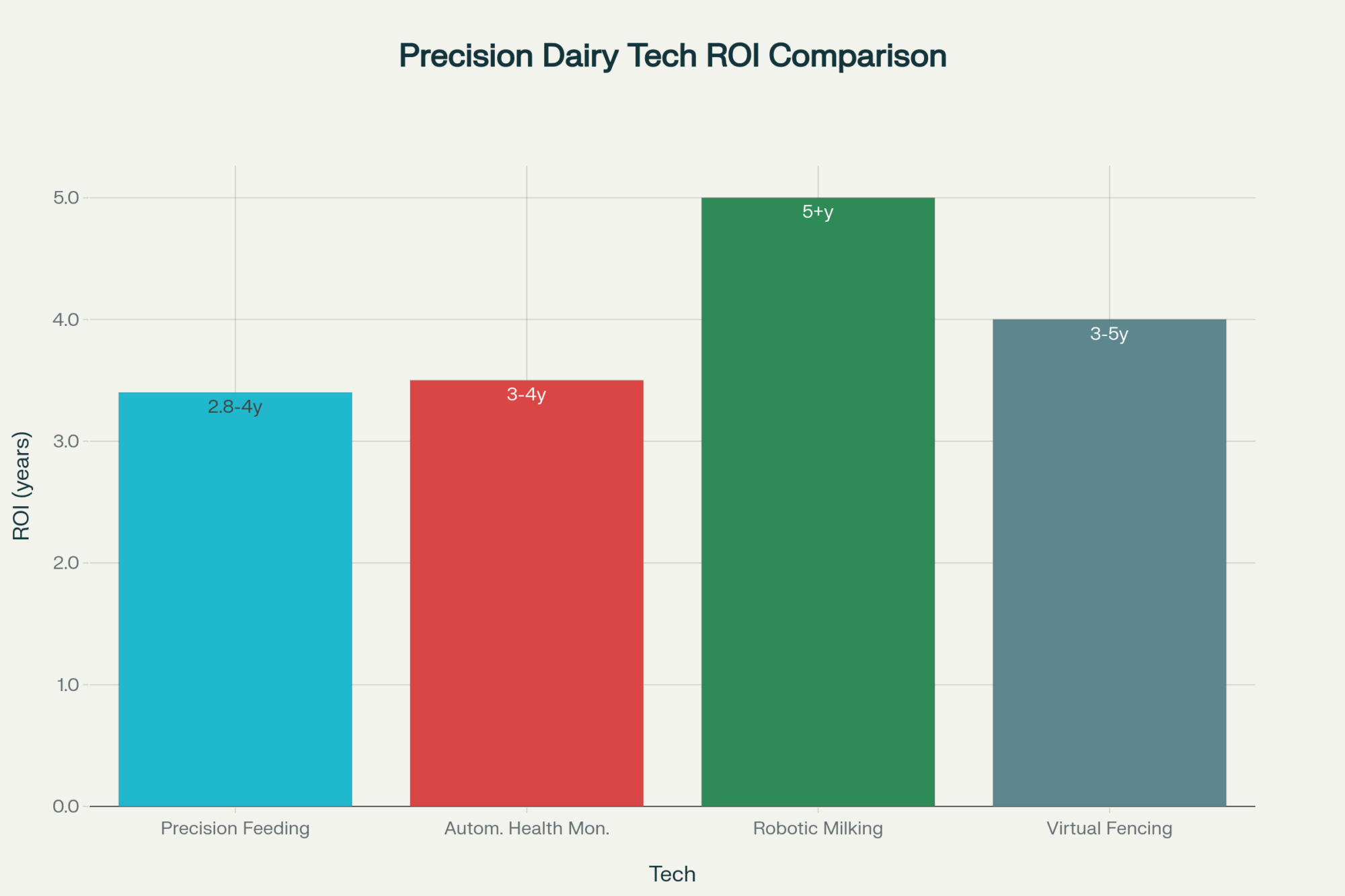

- Achieve your ROI in 2-4 years — Precision feeding pays back the fastest, often within 3 years. Virtual fencing and health monitoring follow close behind. Even robotic milking, with its higher upfront costs, delivers solid returns when labor savings and consistent protocols are factored in. Here’s the takeaway: these technologies aren’t just shiny toys. They’re real tools that can put more money in your pocket and give you more time for what matters. If you haven’t looked into precision feeding, robotic milking, or AI health tools yet, you’re missing a trick in today’s fast-evolving dairy game.

With volatile milk prices squeezing dairy margins, farmers are turning to precision technology not just to survive, but to thrive. With Class I and Class III prices hovering around $18 and $17 per hundredweight, operations utilizing AI and automation are discovering smarter ways to reduce costs and increase yields.

The precision dairy-tech market is projected to reach $5.59 billion by 2025 and is expected to expand at a rate of 9-15% annually, driven by tangible on-farm benefits. Early adopters report slashing labor costs by 20-50% and lifting milk yields by 10-20%, according to a Data Bridge Market Research report.

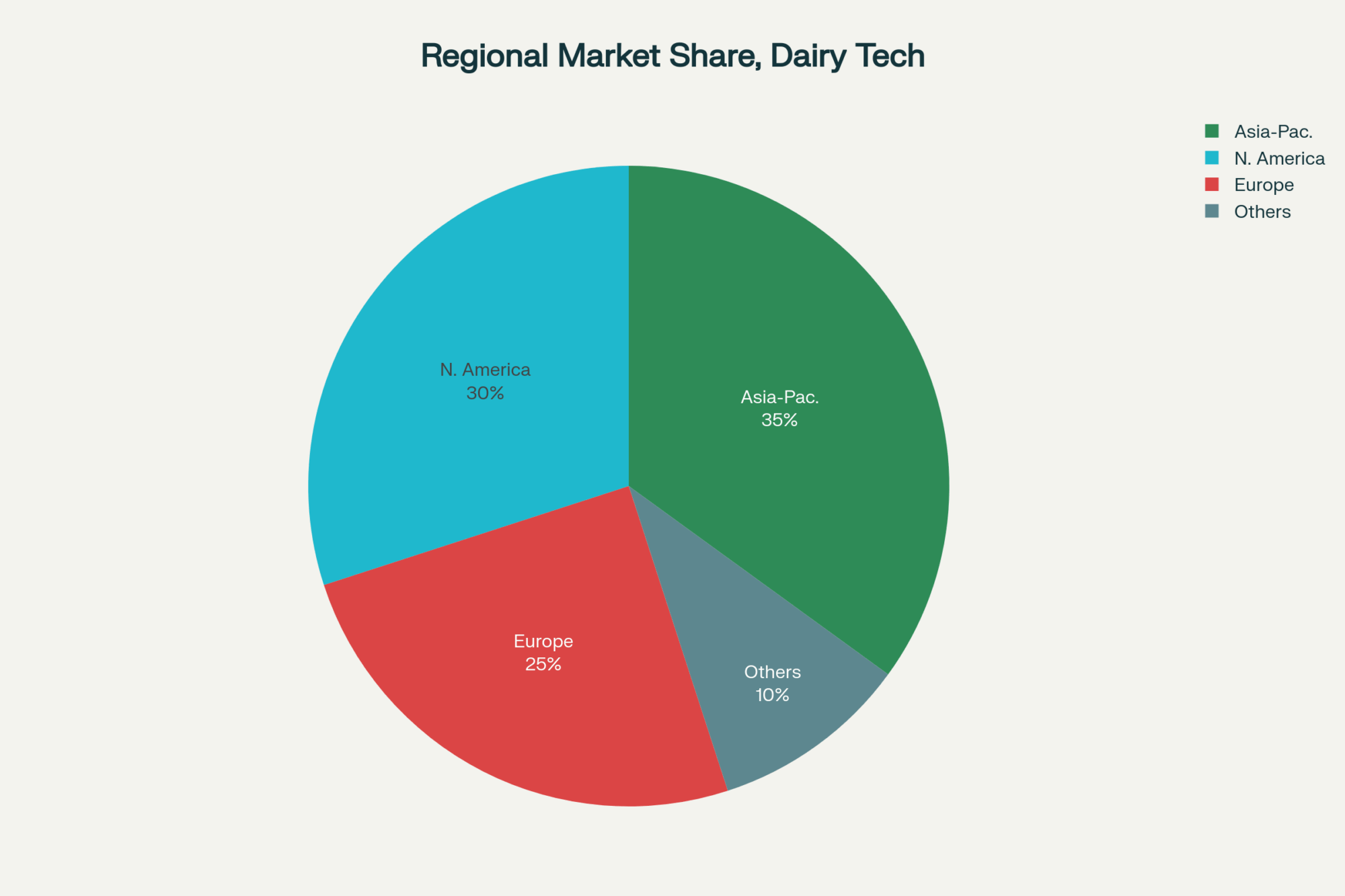

Regionally, North America accounts for about 30% of the market, driven by labor cost pressures and solid tech infrastructure. European advances are driven by strict environmental and welfare regulations that encourage precision livestock farming tools. The Asia-Pacific is the fastest-growing market segment, modernizing dairy farming traditions with AI and robotics at a rate of approximately 6% CAGR.

Health & Reproduction Monitoring: The New Eyes in the Barn

AI health monitoring is no longer just a buzzword. Over one million U.S. cows are under continuous AI surveillance, with research from Liverpool University showing a lameness detection accuracy of nearly 85%. Catching lameness early can save $300-500 per cow annually.

Platforms like CattleEye and Ever.Ag identify heat cycles up to 24 hours before visual detection, leading to conception rate improvements of 8-12%. Dr. Sarah Johnson from Texas A&M confirms these systems can cut vet bills 25-30% while boosting herd fertility—benefits that farms see reflected quickly.

What producers should do: Consult with your veterinarian to select systems that integrate well with your existing herd health programs. Start with one technology rather than trying to implement everything at once.

Precision Feeding: Cutting Costs and Boosting Conversions

Feed costs chew up 50-60% of their total expenses. Precision feeding systems typically pay for themselves within 2 to 4 years, delivering feed savings between 15-25% per cow. European milk prices hold steady at €50.60 per 100 kg, making input control essential.

AI-driven feeding cuts feed expenses 5-10%, saving $200-400 annually per cow, depending on scale and prices. Real-time ration adjustments prevent $50-$ 75 per cow losses caused by nutritional imbalances.

Lucas Fuess from RaboResearch notes this tech improves feed conversion by 15-20%, a crucial edge in tight feed markets.

Implementation advice: Carefully assess your current feed costs and waste patterns to optimize your feed management. Consider exploring government grants or financing options specifically for agricultural technology to help with upfront costs.

Robotic Milking: Why Automation is a Growing Investment

In Ontario, the number of farms using robotic milking systems doubled between 2016 and 2021, with many reporting milk yield gains of 2.5 to 2.9 kg per cow per day due to consistent milking protocols that reduce stress and allow for more frequent milking.

Mike Thompson from Progressive Dairy Solutions points out that robots don’t just replace labor—they trim $15-25k annually in labor turnover costs by keeping milking protocols reliable.

Key considerations: Ensure you have reliable system support and invest heavily in crew training. The technology is only as good as the management behind it.

Pasture Management Reinvented: The Rise of Virtual Fencing

Virtual fencing contains herds 99% of the time, cuts fencing maintenance by as much as $15,000, and frees up 20-40 labor hours weekly. The GPS-enabled collars guide cattle movement through audio cues and mild stimulation, eliminating most physical barriers.

University of Wisconsin research highlights a 17% boost in pasture utilization, converting underused land into productive feed. Recent regulatory approvals in areas such as New South Wales further support the adoption.

Before implementing: Evaluate local regulations and ensure you have strong cellular coverage. Begin by testing the effectiveness of a small section of your operation.

Typical ROI Timelines and Primary Benefits

- Precision Feeding: 2-4 years – Feed cost savings (15-25%)

- Automated Health Monitoring: 3-4 years – Reduced vet bills, increased yield

- Robotic Milking: 5+ years – Labor savings, increased milk yield

- Virtual Fencing: 3-5 years – Labor savings, enhanced pasture use

Scale matters: smaller farms (50-200 cows) see fastest payback through health monitoring and precision feeding. Larger operations benefit more from robotic milking and integrated automation systems.

The Real Challenges of Adopting Precision Tech

Adoption is not without its challenges. Nearly 30% of tech projects stall due to tight cash flow and inadequate staff training, according to Dr. Jennifer Walsh of Cornell. Training, management buy-in, and ongoing education are decisive factors.

Training & Management: Success requires time and investment in staff education, as well as new management skills to interpret and act on data. Many farms underestimate this learning curve.

Maintenance & Support: Equipment downtime can quickly erode expected savings. Establish relationships with reliable local dealers and develop comprehensive support plans before installation.

Data & Integration: Many systems lack effective communication, resulting in frustrating data silos. Invest in a central farm management platform for seamless integration—budget for additional software and consulting costs.

Cybersecurity: Connected operations must protect their data from growing cyber threats. Develop and regularly update data protection plans, as well as security protocols.

Solutions: Explore government financing programs, start with pilot projects, and prioritize vendor relationships with strong local support networks.

Looking Ahead: What the Future Holds

Precision tech adoption is forecast to triple by 2030. Mike North at EverAg warns that farms ignoring automation will face shrinking margins as labor becomes tighter and costs escalate.

Those embracing these technologies early enjoy not only cost savings but also improved animal welfare and sustainability certifications that open doors to premium markets, which are increasingly demanding transparency and environmental stewardship.

Bottom Line

The drive to precision technology isn’t a fad—it’s a strategic imperative for farms of all sizes. While the benefits are clear, success hinges on thoughtful planning, solid financing, committed training, and a willingness to evolve management practices.

The farms that will win in the long term won’t be those that buy the fanciest gadgets first—they’ll be the ones that better harness these tools to become smarter, more resilient businesses. Technology is the enabler; smart management remains the differentiator.

Start small, plan thoroughly, and remember: the goal isn’t just to adopt technology, but to use it strategically to build a more profitable and sustainable operation.

This analysis draws on the latest USDA data, peer-reviewed research from universities such as Liverpool and Wisconsin, and insights from leading dairy market analysts, extending through 2025.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- Profit and Planning: 5 Key Trends Shaping Dairy Farms in 2025 – This article takes a step back from specific technologies to focus on the big-picture economic trends. It reveals how to leverage technology to navigate volatile markets, offering actionable advice on feed conversion ratios, genomic testing, and cleaning up your balance sheet to prepare for future investments.

- The Robotics Revolution: Embracing Technology to Save the Family Dairy Farm – Beyond the headlines, this piece provides practical insights and case studies from real farms that have successfully implemented robotic milking systems. It demonstrates how to calculate ROI, busts common myths about automation, and shows how robots can transform a farm’s labor structure and improve quality of life.

- 5 Technologies That Will Make or Break Your Dairy Farm in 2025 – This article delves deeper into the specifics of cutting-edge technology, from next-generation calf monitoring to advanced TMR systems. It highlights the tangible benefits and potential savings, providing a roadmap for what to invest in and what to expect in return.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!